Aliphatic-aromatic copolyester and preparation method thereof

An aromatic and copolyester technology, which is applied in the field of preparation of aliphatic-aromatic copolyesters, can solve the problems of high melt index and low melt viscosity of aliphatic-aromatic copolyesters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

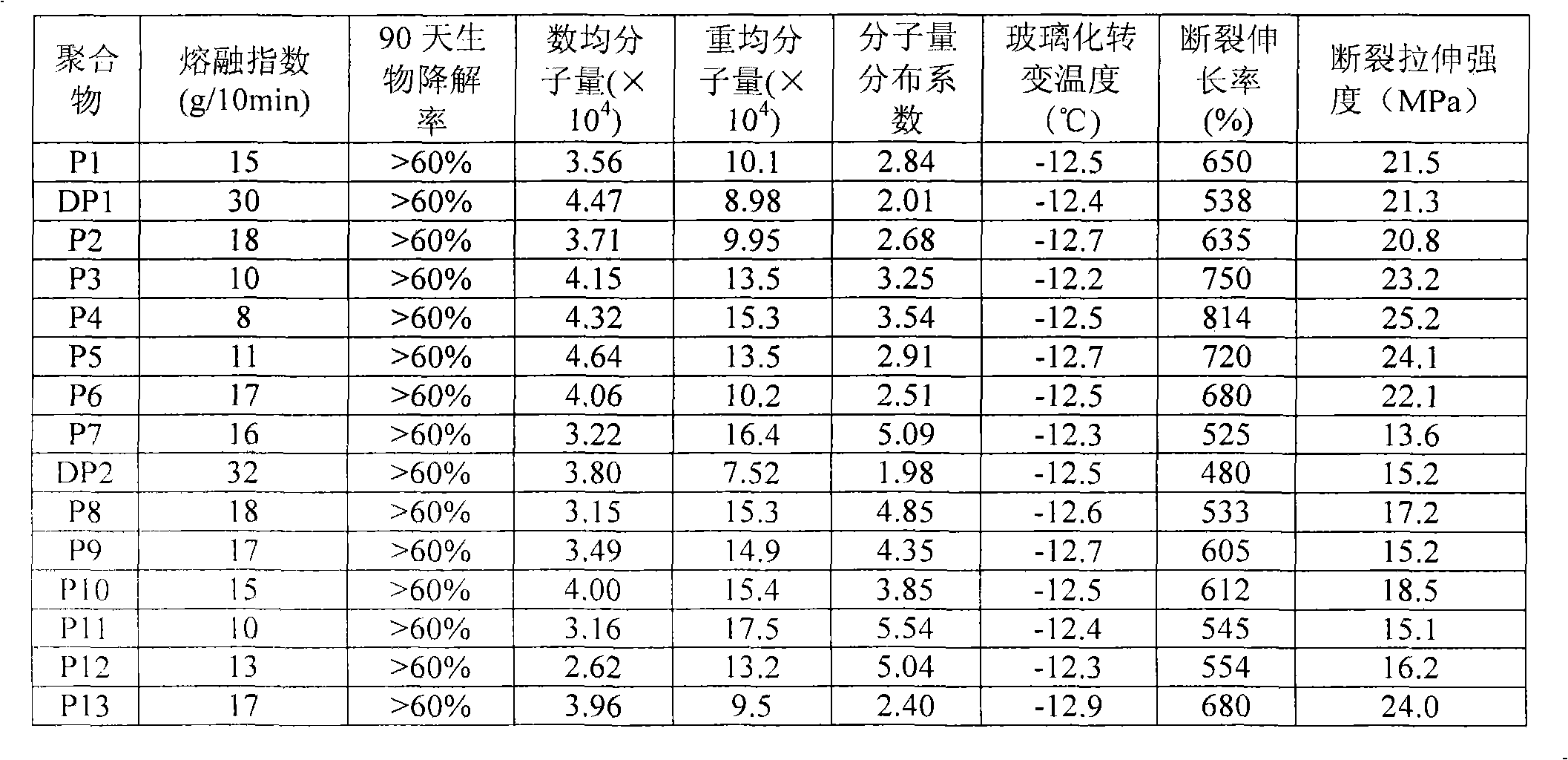

Examples

preparation example Construction

[0015] According to a first aspect of the present invention, the present invention provides a kind of preparation method of aliphatic-aromatic copolyester, the method comprises the following steps:

[0016] (1) Under transesterification reaction conditions, make component a and component b carry out contact reaction in the presence of catalyst, the molar ratio of the addition amount of component a and component b is 1: 0.8-3, and described catalyst containing a first catalyst, and optionally a second catalyst;

[0017] (2) Under esterification reaction conditions, in the presence of the first catalyst and the second catalyst, the reaction mixture obtained in step (1), component c, component d and the optionally added component Part b carries out contact reaction, the molar ratio of the total addition amount of described component a and component c and the total addition amount of described component b is 1: 0.8-6;

[0018] (3) under polycondensation reaction conditions, the r...

Embodiment approach

[0022] According to an embodiment of the present invention, the process of above-mentioned steps (1) and (2) may include:

[0023] Under transesterification reaction conditions, make component a and component b carry out transesterification reaction in the presence of the first catalyst, the molar ratio of the addition amount of component a and component b is 1: 0.8-3, is preferably 1 : 1-3, more preferably 1.2-2.5;

[0024] The reaction mixture obtained by the transesterification reaction, component c, component d and the second catalyst are mixed, and component b is selectively added, so that the total amount of the component a and component c added is the same as that of the component The molar ratio of the total added amount of part b is 1:0.8-6 (preferably 1:1.15-2.5), and then the reaction takes place under the esterification reaction conditions.

[0025] According to another embodiment of the present invention, the process of above-mentioned steps (1) and (2) may inclu...

Embodiment 1

[0059] This example is used to illustrate the aliphatic-aromatic copolyester and its preparation method provided by the present invention.

[0060] Add 1.72mol of dimethyl terephthalate, 2.77mol of 1,4-butanediol and 0.72mmol of tetrabutyl titanate to a 2.5L reactor, stir and heat to reflux under a nitrogen atmosphere, and adjust the temperature to 200°C and react at this temperature. When the methanol generated by the reaction is completely distilled off (the reaction is carried out for about 100 minutes), add 1.86mol of 1,4-butanedioic acid and 2.22mol of 1,4-butane Diol, the pentaerythritol of 7.34mmol and the lanthanum stearate of 0.62mmol continue to heat and stir to reflux, the temperature is adjusted to 220 ℃ and react at this temperature, when the water generated by the reaction is completely steamed out (the reaction is carried out for about 100 minutes) ), adjust the absolute pressure in the reactor to below 200Pa, adjust the temperature to 240°C, and polycondense at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com