Biodegradable film modified by epoxidized lignin and preparation method thereof

A biodegradation and lignin technology, applied in the field of polymer materials, can solve the problems of poor processing performance, high production cost and low strength of biodegradable films, and can solve the problems of reduced processing performance and mechanical properties, good environment, and improved melt. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

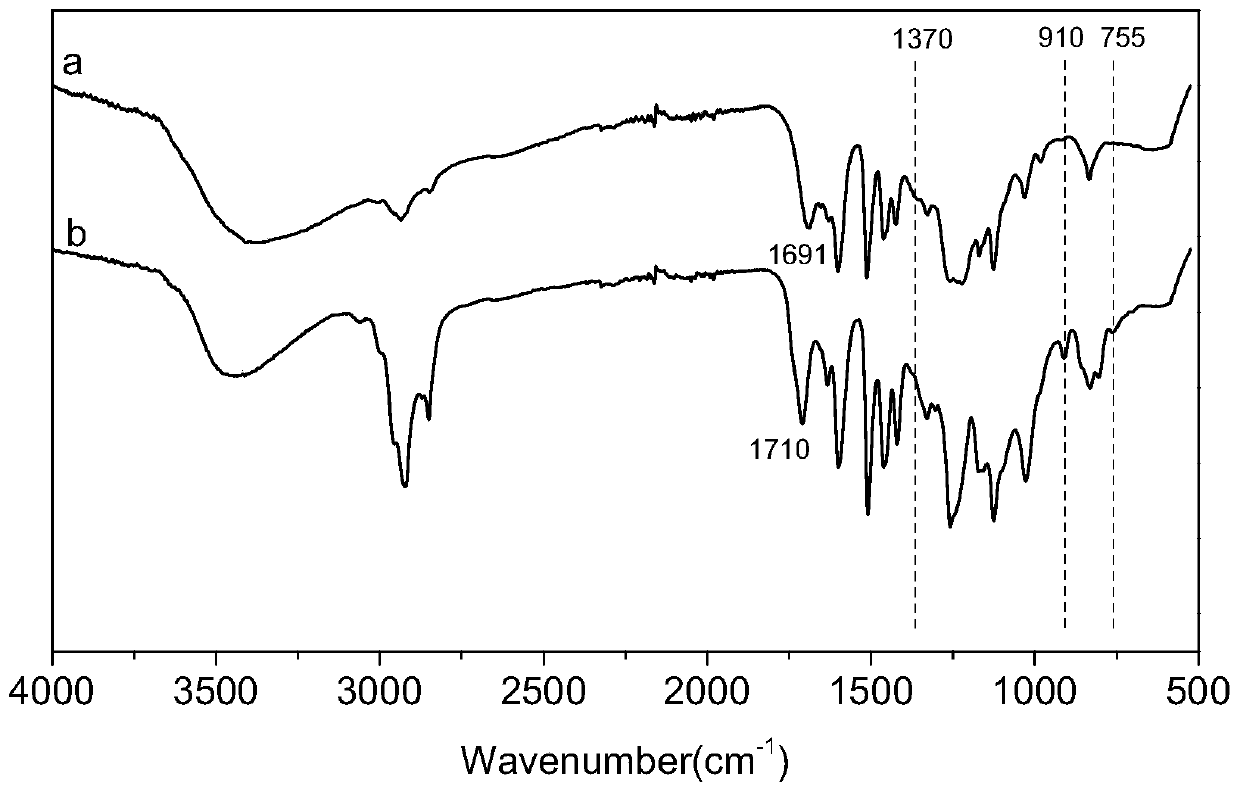

Image

Examples

Embodiment 1

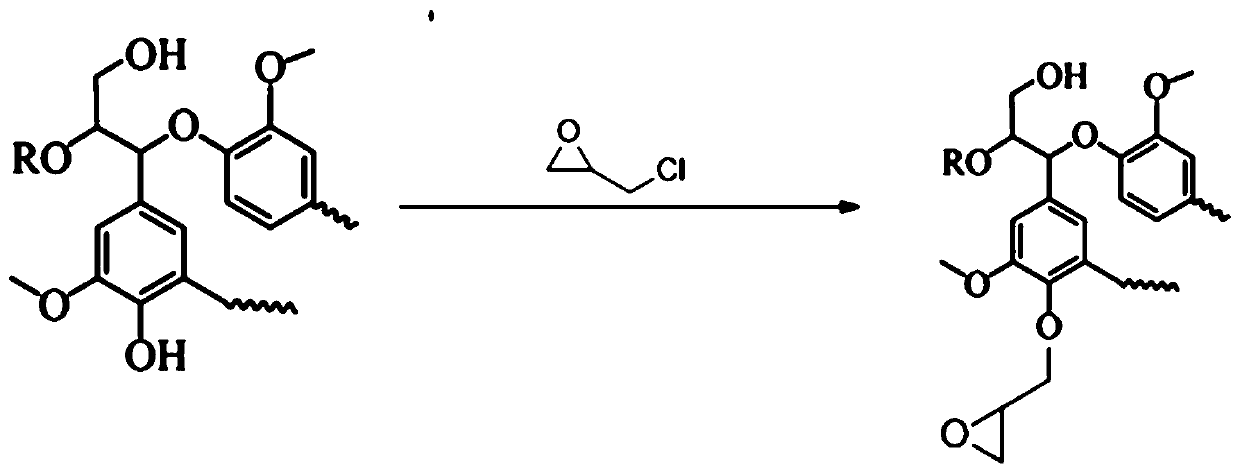

[0047] (1) Disperse alkali lignin at a mass ratio of 1:20 in a mixed solution made of 50 parts of water / acetone at a volume ratio of 1:1, filter to remove insoluble matter, and then add 3 parts of sodium hydroxide and 20 parts of epoxy Add chloropropane into the mixed solution, stir and react at 55°C for 5 hours, then add 50 parts of water, adjust the pH to 3.5 with 0.1M hydrochloric acid, wash the solid collected by filtration with water to remove residual acid, dry and pulverize to obtain epoxidized wood white. Among them, the alkali lignin is obtained from the black liquor of corncob and straw after alkali cooking;

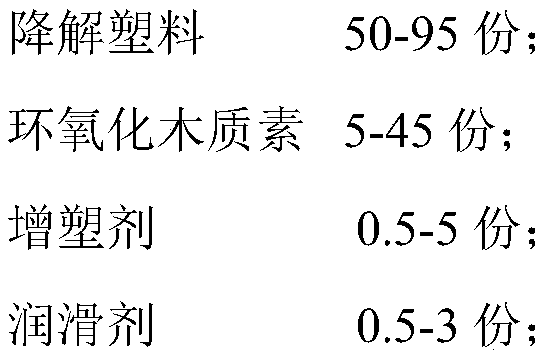

[0048] (2) Add 60 parts of PBAT, 10 parts of PLA, 30 parts of epoxidized lignin described in step (1), 3 parts of tributyl citrate, 2 parts of zinc stearate in the high mixer, with 800rpm Rotating speed, mix 20min, obtain premix;

[0049] (3) Mix the premix described in step (2) with a twin-screw extruder and then granulate to obtain modified particles. The t...

Embodiment 2

[0052](1) Disperse enzymatic lignin in a mixed solution made of 50 parts of water / acetone with a volume ratio of 1:1 at a mass ratio of 1:20, filter to remove insoluble matter, and then add 3 parts of sodium hydroxide and 20 parts of ring Add oxychloropropane to the mixed solution, stir and react at 55°C for 5 hours, then add 50 parts of water, adjust the pH to 3.5 with 0.1M hydrochloric acid, wash the solid collected by filtration with water to remove residual acid, dry and pulverize to obtain epoxidized Lignin; the enzymatic lignin is obtained from the residue of corncobs and straws enzymatically hydrolyzed by cellulase;

[0053] (2) add 45 parts of PBAT, 30 parts of PBS, epoxidized lignin described in 25 parts of steps (1), 2 parts of triacetin, 1 part of ethylene bis stearic acid amide in high mixer, with The rotating speed of 1000rpm, mix 10min, obtain premix;

[0054] (3) Mix the premix described in step (2) with a twin-screw extruder and then granulate to obtain modifi...

Embodiment 3

[0057] (1) Disperse enzymatic lignin in a mixed solution made of 50 parts of water / acetone with a volume ratio of 1:1 at a mass ratio of 1:20, filter to remove insoluble matter, and then add 3 parts of sodium hydroxide and 20 parts of ring Add oxychloropropane to the mixed solution, stir and react at 55°C for 5 hours, then add 50 parts of water, adjust the pH to 3.5 with 0.1M hydrochloric acid, wash the solid collected by filtration with water to remove residual acid, dry and pulverize to obtain epoxidized Lignin; the enzymatic lignin is obtained from the residue of corncobs and straws enzymatically hydrolyzed by cellulase;

[0058] (2) add 50 parts of PBS, 25 parts of PLA, epoxidized lignin described in 25 parts of step (1), 2 parts of triacetin, 1 part of ethylene bis stearic acid amide in high mixer, with The rotating speed of 1000rpm, mix 10min, obtain premix;

[0059] (3) Mix the premix described in step (2) with a twin-screw extruder and then granulate to obtain modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com