Preparation method of adhesive for outer layer of aluminum plastic film of lithium battery

A lithium battery and aluminum-plastic film technology, applied in the direction of adhesives, etc., can solve the problems that the application properties of adhesives such as bonding, extension, and stretching are difficult to meet the performance requirements of lithium batteries for aluminum-plastic films, and achieve reasonable molecular weight distribution. Good hydrolysis resistance, good flexibility and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

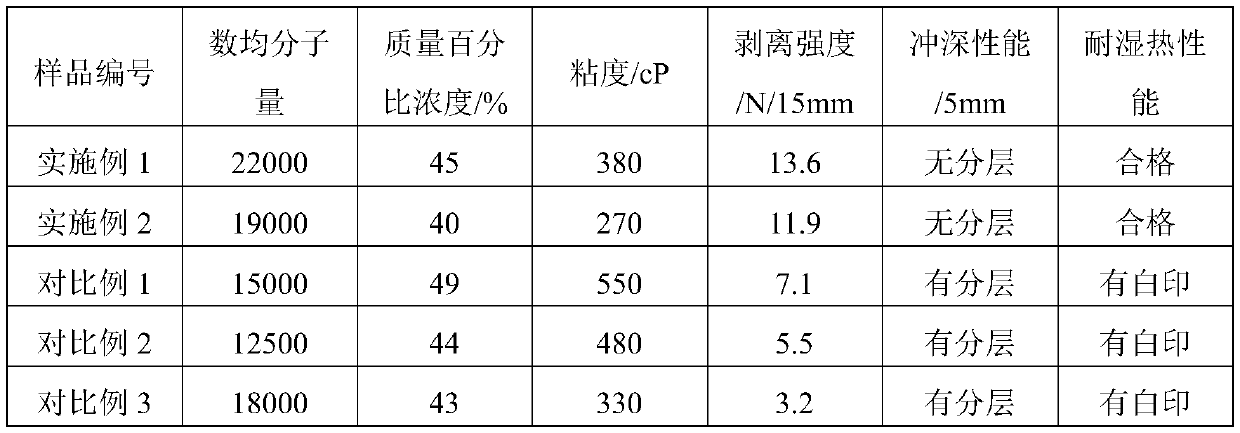

Embodiment 1

[0028]Add 181.8g99% of 1,3-butanediol and 147.5g99% of 1,6-adipic acid into the reaction flask, add 0.4g of tetrakis (3,5-di-tert-butyl-4-hydroxyhydrocinnamic acid) For pentaerythritol ester, replace the air in the reaction system with nitrogen, then raise the temperature to 100°C under the protection of nitrogen, start stirring after the solid material melts, and raise the temperature to the esterification reaction temperature of 160°C at a speed of 30°C / h, and carry out the heat preservation reaction 2h. Then continue to slowly heat up to 210°C, add a mixture of 21.0g99% phthalic acid and 62.9g99% terephthalic acid, react for 2h, then heat up to the polycondensation reaction temperature of 270°C, add 27.4g98% trimethylol Propane, after continuing to react for 0.5h, add 0.12g of dibutyltin oxide, and carry out decompression reaction under 60Pa absolute pressure for 4h, and obtain a polymer with a target molecular weight of 22,000. Then under the reaction temperature, restore...

Embodiment 2

[0030] Add 298.0g 99% 3-methyl-1,5-pentanediol and 166.7g 99% 1,5-pentanedioic acid into the reaction flask, add 0.6g 2,4-dimethyl-6-tert-butylphenol After replacing the air in the reaction system with nitrogen, the temperature was raised to 100°C under the protection of nitrogen. After the solid material melted, stirring was started, and the temperature was raised to the esterification reaction temperature of 170°C at a rate of 30°C / h, and the heat preservation reaction was carried out for 2 hours. Then continue to slowly heat up to 220°C, add a mixture of 28.0g99% phthalic acid and 55.9g99% terephthalic acid, react for 2h, then heat up to the polycondensation reaction temperature of 260°C, add 14.1g99% glycerol, After continuing the reaction for 0.5 h, 0.26 g of zinc isooctanoate was added, and the decompression reaction was carried out at an absolute pressure of 100 Pa for 4 h to obtain a polymer with a target molecular weight of 19,000. Then under the reaction temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com