A kind of glue for lithium battery aluminum-plastic film outer layer and synthesis method thereof

A technology of glue and synthesis method for the outer layer, applied in the direction of adhesives, etc., can solve the problems of difficult to control the reaction speed, uneven molecular distribution, wide molecular weight distribution, etc., and achieve reasonable molecular weight distribution, simple and easy to control operation process, and high application performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

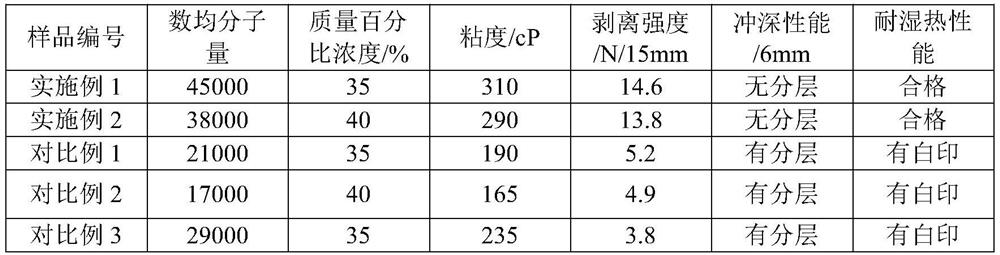

Examples

Embodiment 1

[0035] Add 461.1g of 99% 1,2-propanediol, 407.3g of 99% 1,7-pimelic acid and 422.5g of 99% terephthalic acid into the 2.5L esterification kettle, then add 1.3g of triphenyl phosphite and 0.4g of Antimony oxide, after replacing the reaction system with nitrogen, heated up to 90°C, when the solid material was melted, started stirring, and heated up to the esterification reaction temperature of 170°C at a speed of 40°C / h, carried out a heat preservation reaction for 2h, and then added 34.6g of 99% The maleic anhydride was heated to 200°C and continued to react for 3h, the reaction material was transferred to a decompression reactor, the temperature was controlled to 130°C, 21.2g bisphenol A epoxy resin E44 and 0.4g triethanolamine were added, and the absolute pressure was 20KPa. The ring-opening reaction was carried out for 3h under the following conditions, and when the stirring power of the reactor reached 63-65W, the pressure of the reactor was restored to normal pressure with ...

Embodiment 2

[0037] Add 429.9g 99% ethylene glycol, 384.0g 99% 1,5-glutaric acid and 482.9g99% isophthalic acid into the 2.5L esterification kettle, and then add 0.9g tetra(3,5-di-tert-butyl) -4-Hydroxyhydrocinnamic acid) pentaerythritol ester and 0.7 g of zinc isooctanoate, after replacing the reaction system with nitrogen, the temperature is raised to 90 ° C, when the solid material is melted, the stirring is started, and the temperature is raised to the esterification reaction at a speed of 30 ° C / h The temperature was 180°C, the reaction was kept for 3h, then 59.8g of 99% phthalic anhydride was added, the temperature was raised to 210°C and the reaction was continued for 4h, the reaction material was transferred to the decompression reactor, the temperature was controlled to 110°C, and 10.8g of 1,4-butanediol was added. Diglycidyl ether and 0.3g dimethylethanolamine were subjected to a ring-opening reaction at 30KPa absolute pressure for 4h. When the stirring power of the reactor reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com