Method for preparing epoxy chloropropane by cyclizing chloropropene

A technology of epichlorohydrin and chloropropene, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing, etc., can solve the problems of difficult control of reaction temperature, low conversion rate of epichlorohydrin, etc. The effect of not heating in time, inhibiting side reactions, improving conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

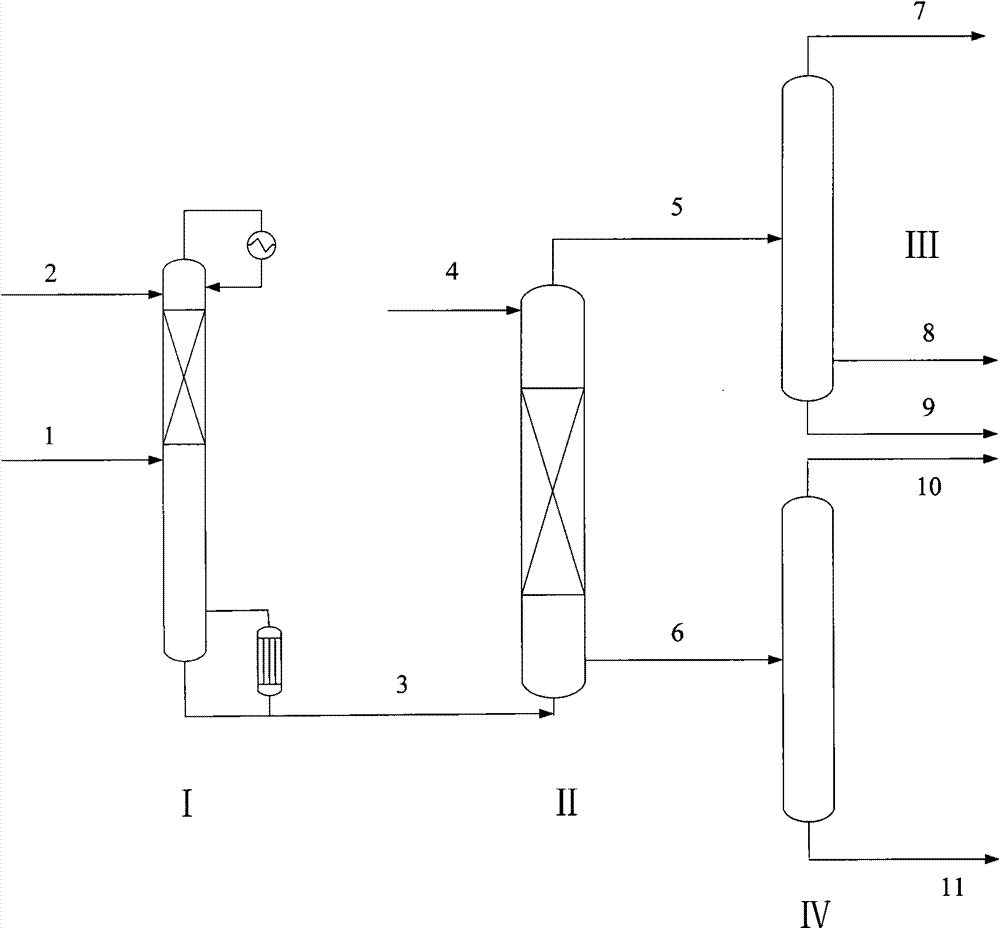

[0023] according to figure 1 As shown, the theoretical plate number of the stripping section of the catalytic distillation column is 15, the separation efficiency of the catalytic reaction section is equivalent to the theoretical plate number of 18, and the catalyst is SiO 2 / TiO 2 The titanium-silicon molecular sieve with a molar ratio of 80, 30% by weight of hydrogen peroxide and methanol mixture (methanol content of 70% by weight) entered the first theoretical plate (counting from top to bottom, the same below) at a flow rate of 1.00 g / min. The flow rate of 2.00 g / min enters from the bottom of the catalytic reaction section, the operating temperature of the reaction section is 43 to 48 °C, the weight ratio of the first part of the tower to the second part of the material is 3:1, and the bottom of the tower is extracted with a flow of 3.00 g / min, The bottom of the tower is drawn into the top of the extraction tower with a theoretical plate number of 15, the extractant water...

Embodiment 2

[0025] according to figure 1 As shown, the theoretical plate number of the stripping section of the catalytic distillation column is 30, the separation efficiency of the catalytic reaction section is equivalent to the theoretical plate number of 50, and the catalyst is SiO 2 / TiO 2 Molar ratio of 180 titanium-silicon molecular sieve, 50% by weight of hydrogen peroxide and methanol mixture (methanol content of 30% by weight) at a flow rate of 1.00 g / min, and propene chloride at a flow rate of 12.00 g / min from the top of the catalytic distillation column to enter, the reaction section The operating temperature is 38-43°C, the weight ratio of the first part of the column to the second part of the material is 1:1, the bottom of the column is extracted at a flow rate of 13.00 g / min, and the bottom of the column is extracted into an extraction column with a theoretical plate number of 40 At the top, the extraction agent ethylene glycol enters the bottom of the extraction tower at 2...

Embodiment 3

[0027] according to figure 1 As shown, the number of theoretical plates in the stripping section of the catalytic distillation column is 5, the separation efficiency of the catalytic reaction section is equivalent to 5 theoretical plates, and the catalyst is SiO 2 / TiO 2 Molar ratio of 20 titanium-silicon molecular sieves, 2 wt% hydrogen peroxide and methanol mixture (methanol content of 50 wt%) entered the first theoretical plate at a flow rate of 1.00 g / min, and propene chloride flowed from the middle of the catalytic reaction section at a flow rate of 5 g / min Entering, the operating temperature of the reaction section is 42-46 °C, the weight ratio of the first part of the tower to the second part of the material is 15:1, the bottom of the tower is extracted at a flow rate of 6.00 g / min, and the number of theoretical plates extracted from the bottom of the tower is 5 At the top of the extraction tower, the extraction agent 1,3-propanediol enters the bottom of the extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com