High-strength nano solid waste concrete prepared from iron oxide hollow spheres and method thereof

A waste concrete and hollow sphere technology, applied in the field of building materials, can solve the problems of failing to improve the compactness and impermeability of concrete, being unsuitable for preparing high-strength solid waste concrete, and difficult to improve the strength of concrete, so as to improve the creep resistance. Ability, fracture toughness improvement, strength improvement effect

Active Publication Date: 2021-10-08

ANGANG STEEL CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It uses iron ore tailing waste rock and river sand instead of iron tailing sand, and uses expensive nano-titanium dioxide, which has a single purpose and fails to improve the performance of concrete such as compactness and impermeability, and has poor practicability and economy.

[0006] The above patents use some solid waste and nano-materials, but it is difficult to improve the strength of concrete, so it is not suitable for the preparation of high-strength waste concrete

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

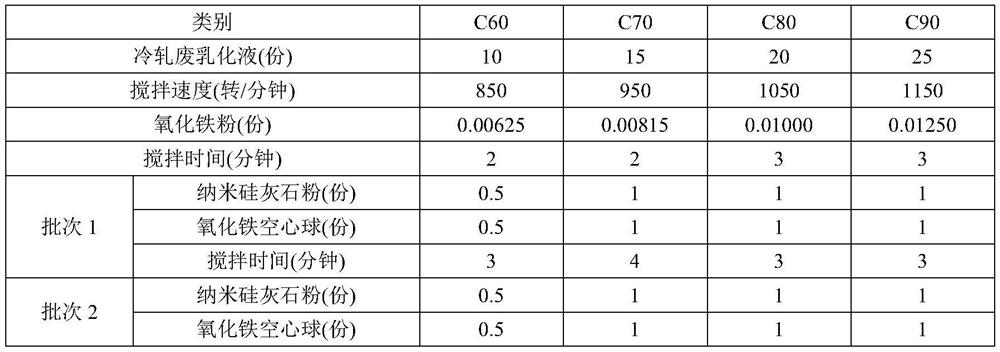

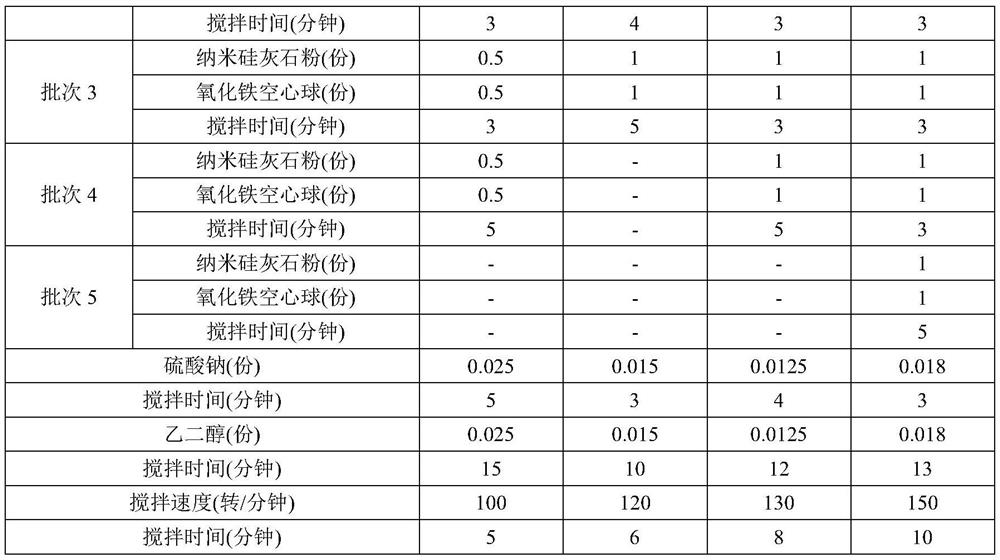

[0077] Embodiment 1: (unit in the concrete proportioning scheme: part; 28d strength unit: MPa)

[0078]

Embodiment 2

[0079] Embodiment 2: (unit in the concrete proportioning scheme: part; 28d strength unit: MPa)

[0080]

Embodiment 3

[0081] Embodiment 3: (unit in the concrete proportioning scheme: part; 28d strength unit: MPa)

[0082]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides high-strength nano solid waste concrete prepared from iron oxide hollow spheres and a method thereof, and the concrete comprises the following components: 100 parts of a cementing material, 155-196 parts of coarse aggregate, 132-282 parts of fine aggregate, 2.2-2.8 parts of a high efficiency water reducing agent, an admixture mainly composed of 2-5 parts of nanometer wollastonite powder, 2-5 parts of iron oxide hollow spheres, 1-4 parts of converter secondary dedusting ash, 10-25 parts of cold rolling waste emulsion, 0.0125-0.025 part of sodium sulfate, 0.00625-0.0125 part of iron oxide powder and 0.0125-0.025 part of ethylene glycol, and 29-32 parts of water. The preparation method comprises the following steps: mixing the coarse aggregate and the fine aggregate, adding the cementing material, conducting mixing, adding the high-efficiency water reducing agent and the make-up water, conducting mixing, conducting stirring, injecting the formed mixture into a concrete transport vehicle, and adding the converter digested secondary dedusting ash and the dispersed nanometer wollastonite powder before or simultaneously adding the water reducing agent and the make-up water. Dispersion of the nanometer material is promoted through the iron oxide hollow spheres, the strength of the nanometer solid waste concrete is improved, the mixing amount of metallurgical solid waste in the concrete is larger than or equal to 75%, and high-value utilization of the metallurgical solid waste is achieved.

Description

technical field [0001] The invention belongs to the field of building materials, and in particular relates to a method for preparing high-strength nano solid waste concrete by utilizing iron oxide hollow spheres. Background technique [0002] In recent years, researchers have continuously explored the method of adding nanomaterials to modify concrete, and found that the improvement of nanomaterials to concrete mechanics and durability is mainly due to the promotion of hydration, which makes the hydration products uniform, crystallized and dense, and improves the concrete. Mechanisms such as reducing the porosity and refining the micro-cracks under load. Using nano-assembly technology, nano-materials are grown or grafted onto micron-scale mineral admixtures and fibers to form micro-nano multi-scale materials. On the one hand, it can solve the problem that nano-materials can still be uniformly dispersed in concrete under a large amount, and on the other hand. On the one hand,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04

CPCC04B28/04C04B2201/50C04B2201/52C04B18/027C04B18/062C04B18/14C04B18/12C04B14/308C04B22/147C04B24/026C04B2103/302C04B14/043

Inventor 耿继双徐鹏飞王飞吴文浩杨大正钱峰肖会刚张大利刘睿冯硕

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com