Bi-component solvent-free polyurethane adhesive for solar backboard

A solvent-free polyurethane and solar backsheet technology, which is applied in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of insufficient moisture and heat resistance of adhesives, and achieve improved hydrolysis resistance Performance, meeting application performance requirements, good bonding strength and heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

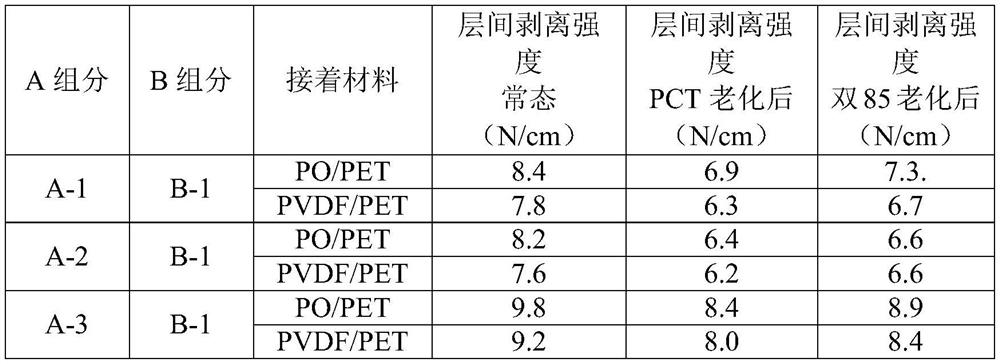

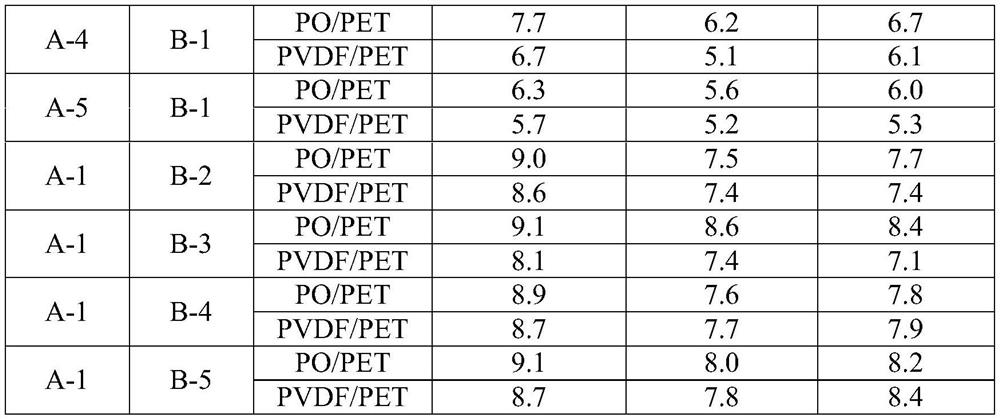

Examples

Embodiment 1

[0027]Preparation of component A-1: 150g of poly-2-methyl-1,3-propylene glycol phthalate (molecular weight 1000), poly-2-methyl-1,3-propylene isophthalate Add 150g (molecular weight 1000), polypropylene glycol 510g (molecular weight 1500) into a 3L reactor, heat to 70-80°C to melt the raw materials, start stirring to 120rpm to mix the raw materials evenly, add 697g of isophorone diisocyanate, and react The temperature of the kettle was raised slowly to 90°C, and after constant temperature reaction for 1 hour, 0.75 g of dibutyltin dilaurate was added as a catalyst, and then the reaction temperature was maintained at 95°C for 1 hour to obtain component A-1. A-1 has a viscosity of 7000 mPa·s at 25°C and an isocyanate group content of 9.23%.

Embodiment 2

[0029] Preparation of component A-2: 150g of polyphthalate-3-methyl-1,5-pentanediol ester (molecular weight 1000), polyisophthalate-3-methyl-1,5- Add 150g of pentylene glycol ester (molecular weight 1000), 510g of polypropylene glycol (molecular weight 1500) into a 3L reaction kettle, heat to 70-80°C to melt the raw materials, start stirring to 120rpm to mix the raw materials evenly, add isophorone diisocyanate 697g, the temperature of the reactor was slowly raised to 90°C, and after constant temperature reaction for 1h, 0.75g of dibutyltin dilaurate was added as a catalyst, and then the reaction temperature was maintained at 95°C for 1h to obtain A component A-2. A-2 has a viscosity of 55000 mPa·s at 25°C and an isocyanate group content of 9.07%.

Embodiment 3

[0031] Preparation of A component A-3: 150g of polyneopentyl glycol phthalate (molecular weight 1000), 150g of polyneopentyl isophthalate (molecular weight 1000), and 510g of polypropylene glycol (molecular weight 1500) were added Put it into a 3L reaction kettle, heat it to 70-80°C to melt the raw materials, start stirring to 120rpm to mix the raw materials evenly, add 697g of isophorone diisocyanate, slowly raise the temperature of the reaction kettle to 85°C, and add catalyst two after constant temperature reaction for 1 hour. 0.75 g of dibutyltin laurate, and then maintain the reaction temperature at 90° C. for 1 h to obtain A component A-3. A-3 has a viscosity of 75000 mPa·s at 25°C and an isocyanate group content of 9.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com