Regeneration method of SCR denitration catalyst

A technology of SCR catalyst and denitration catalyst, applied in the field of catalyst regeneration, can solve the problems of complicated separation and purification procedures, difficulty in separation and purification, and high processing cost, and achieve the effect of saving heavy metal resources, avoiding adverse effects and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

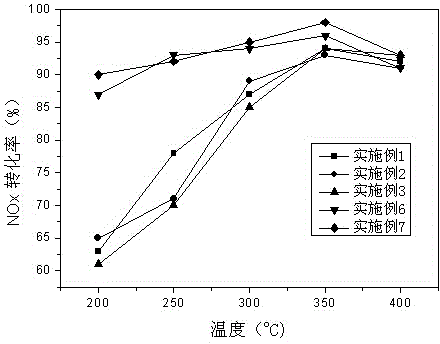

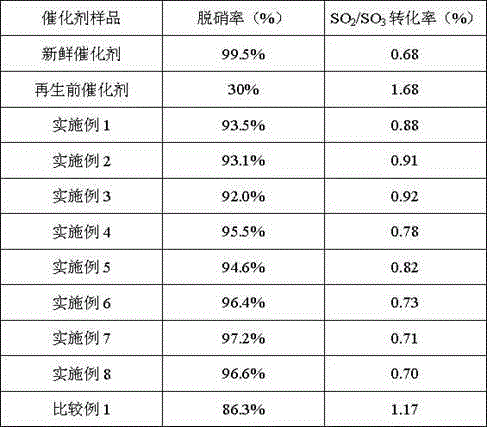

Embodiment 1

[0027] Preparation of cleaning solution: Weigh 0.05Kg of isooctyl alcohol polyoxyethylene ether phosphate, 0.05Kg (0.2%) of ammonium lauryl sulfate, and weigh 49.90Kg (99.8%) of sulfuric acid with an acid molar concentration of 0.5mol / L. Stir for 5 minutes to make it evenly mixed and prepare a 50Kg cleaning solution.

[0028](1) Take the discarded denitrification catalyst and the SCR denitrification monolithic honeycomb catalyst (150×150×1000mm) whose denitrification activity has been reduced from 90% to 30%, and blow it with 0.2MPa oil-free dry compressed air for 30 minutes to clean the surface. and dust accumulation in the hole. Soak the purged catalyst in 50Kg cleaning solution, and make the cleaning solution flush the catalyst for 20 minutes to remove the alkali metals and alkaline earth metals that are bonded to the catalyst and make the catalyst poisoned, then put the catalyst into a blast drying box for The temperature was raised to 100°C at a rate of 10°C / min, and kep...

Embodiment 2

[0034] Preparation of cleaning solution: Weigh 0.05Kg of polyoxyethylene lauryl ether phosphate ammonium salt, 0.05Kg (0.2%) of fatty amine (alkylamine) polyoxyethylene ether, and weigh 0.5mol / L acid molar concentration Sulfuric acid 49.90K (99.8%), stirred for 10 minutes to make it evenly mixed, and prepared as 50Kg cleaning solution.

[0035] (1) Take the discarded denitrification catalyst and the SCR denitrification monolithic honeycomb catalyst (150×150×1000mm) whose denitrification activity has been reduced from 90% to 20% from a factory, and blow it with 0.2MPa oil-free dry compressed air for 30 minutes to remove the surface and dust accumulation in the hole. Soak the purged catalyst in 50Kg cleaning solution, and make the cleaning solution flush the catalyst for 20 minutes to remove the alkali metals and alkaline earth metals that are bonded to the catalyst and make the catalyst poisoned, then put the catalyst into a blast drying box for The temperature was raised to 1...

Embodiment 3

[0041] Preparation of cleaning solution: weigh 0.1Kg of alkylphenol polyoxyethylene ether and 0.1Kg (0.4%) of ammonium lauryl sulfate, weigh 49.80Kg (99.6%) of sulfuric acid with an acid molar concentration of 0.5mol / L, and stir for 15 Minutes, make it mix evenly, and prepare 50Kg cleaning solution.

[0042] (1) Take the discarded denitrification catalyst and the SCR denitrification monolithic honeycomb catalyst (150×150×1000mm) whose denitrification activity has been reduced from 90% to 40% from a factory, and blow it with 0.2MPa oil-free dry compressed air for 30 minutes to remove the surface and dust accumulation in the hole. Soak the purged catalyst in 50Kg cleaning solution, and make the cleaning solution flush the catalyst for 20 minutes to remove the alkali metals and alkaline earth metals that are bonded to the catalyst and make the catalyst poisoned, then put the catalyst into a blast drying box for The temperature was raised to 100°C at a rate of 10°C / min, and kept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com