Finished product prestress steel strand

A technology of prestressed steel strands and prestressed tendons, applied in structural elements, building components, buildings, etc., can solve problems such as affecting the quality of prestressed reinforced concrete structures, prone to twisting and entanglement, and remaining hidden dangers in tensioning operations. To achieve the effect of reducing the hidden danger of tensioning, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

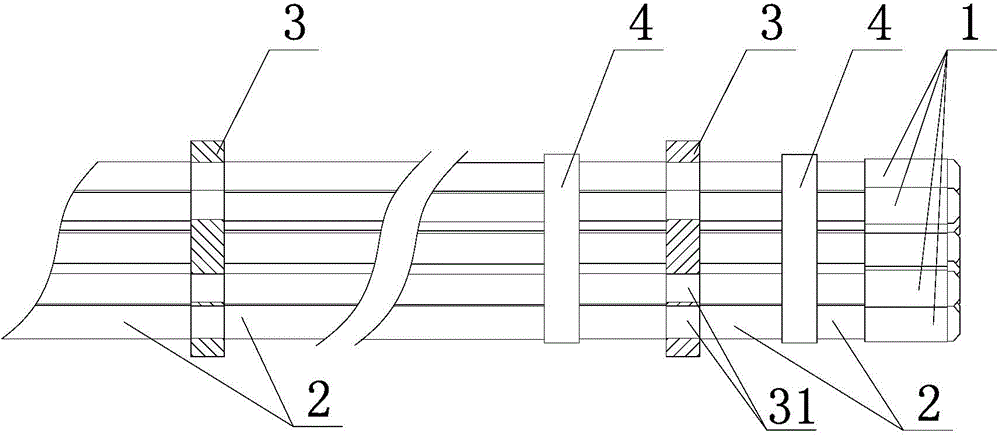

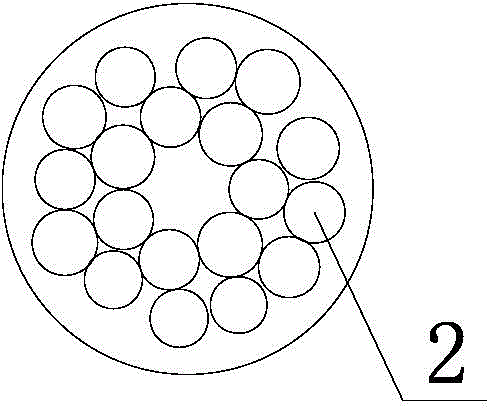

[0028] see Figure 1-Figure 8 Shown, a kind of finished prestressed steel strand bundle, it comprises nineteen prestressed tendon threading devices 1, prestressed tendons 2 and two marking plates 3 matched with the number of prestressed tendon threading devices 1; There are perforations 31 matching the number and diameter of the prestressing tendon threading device 1 on each marking plate 3, and one end of each prestressing tendon 2 passes through the perforation 31 of a marking plate 3 and is fixed in the prestressing tendon threading device 1 , and the other end of the prestressing tendon 2 passes through the perforation 31 at the same position of the other marking plate 3 .

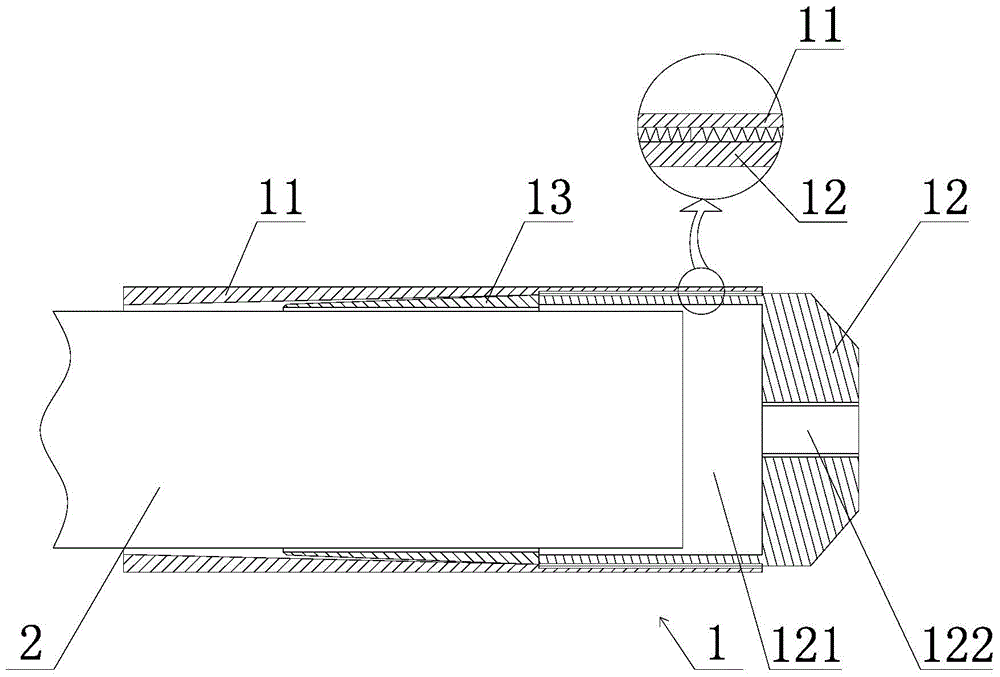

[0029] The prestressing tendon threading device 1 includes an outer sleeve 11, a traction head 12 and four inner clamping pieces 13, the inner wall of the outer sleeve 11 and the outer wall of the traction head 12 are provided with threads in matching positions, and the traction head 12 is screwed toge...

Embodiment 2

[0042] see Figure 9 As shown, a finished prestressed steel strand bundle is different from Embodiment 1 in that the number of whole bundles of prestressed tendons 2 to be threaded is seven, and the overall outer diameter of the seven prestressed tendons 2 is 100 mm; Correspondingly, the quantity of the inner clamping piece 13 is 3 pieces, the length of the inner clamping piece 13 is 50 millimeters, the inner diameter of the inner clamping piece 13 is 49 millimeters, and the outer diameter of the thinner end of the inner clamping piece 13 is 52 mm. mm, the outer diameter of one end of the inner clamping sheet 13 wall thickness is 56 millimeters, and the first included angle α is 3.5 °; the total length of the outer sleeve 11 is 120 millimeters, and the outer diameter is 59 millimeters; the outer sleeve 11 equal wall thickness The inner diameter of the part is 52 mm, the length of the wall thickness gradient part is 48 mm, the inner diameter gradually changes from 52 mm to 51 m...

Embodiment 3

[0044] see Figure 10 As shown, a finished prestressed steel strand bundle is different from Embodiment 1 in that the number of whole bundles of prestressed tendons 2 to be threaded is thirteen, and the overall outer diameter of the thirteen prestressed tendons 2 Correspondingly, the quantity of the inner clamping piece 13 is 4 pieces, the length of the inner clamping piece 13 is 80 millimeters, the inner diameter of the inner clamping piece 13 is 74 millimeters, and the outer diameter of one end of the inner clamping piece 13 is thinner. 78 mm, the outer diameter of one end of the inner clamping sheet 13 wall thickness is 80 mm, and the first angle α is 4.6 °; the total length of the outer sleeve 11 is 200 mm, and the outer diameter of the outer sleeve 11 is 88 mm, and the outer sleeve The inner diameter of the part of the same wall thickness of the sleeve 11 is 78 mm, the length of the wall thickness gradual change part of the outer sleeve 11 is 80 mm, the inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com