Full-automatic shower curtain hole locking device and operation method

A fully automatic, curtain lock technology, applied in the field of sewing machines, can solve problems such as low efficiency, achieve high efficiency, facilitate batch installation, and facilitate transportation and handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

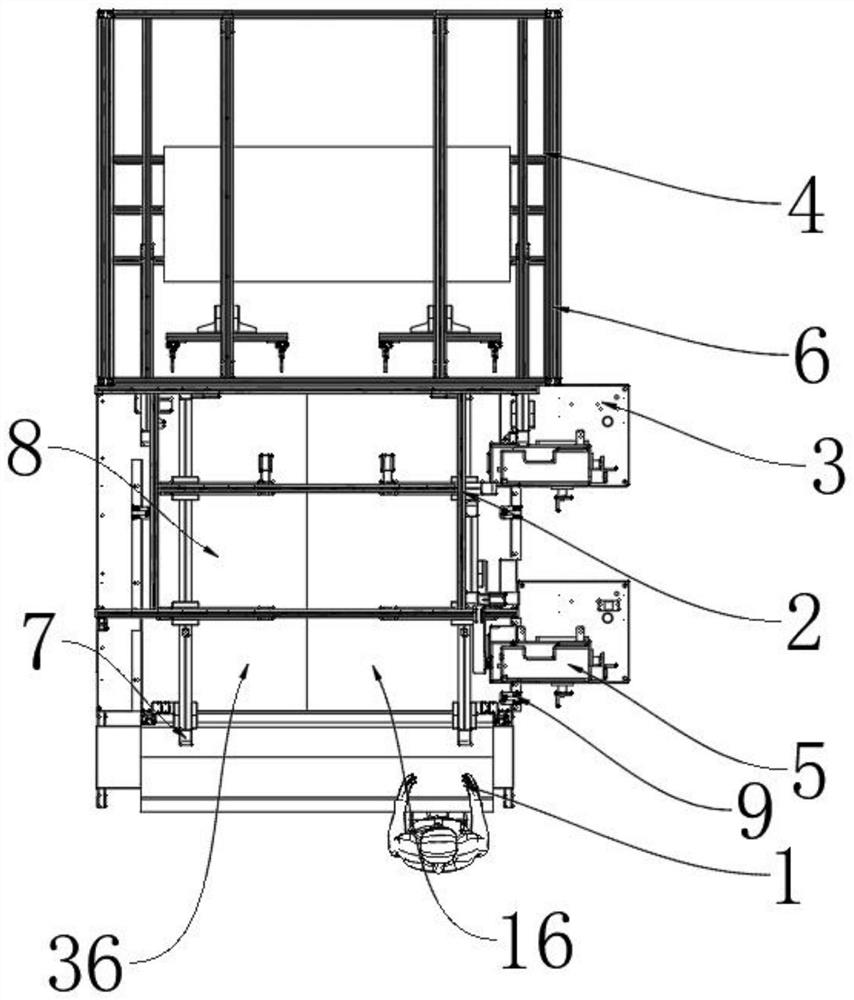

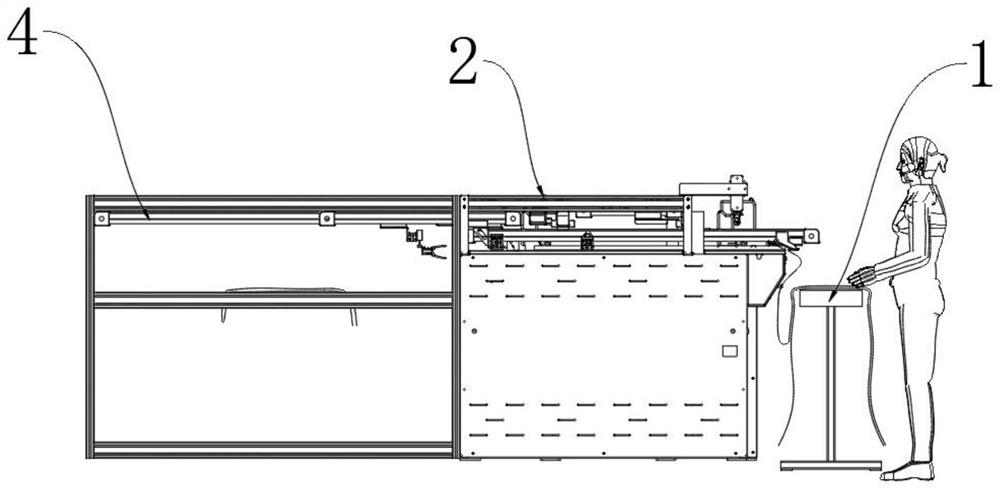

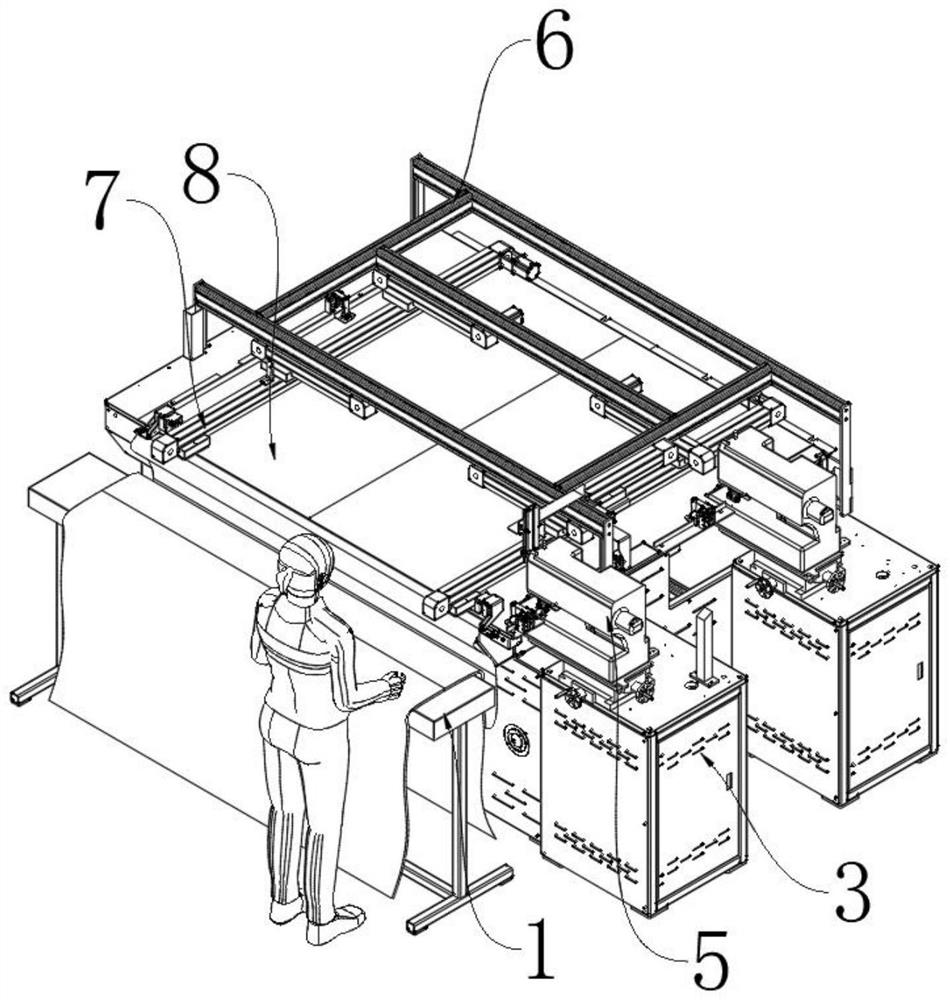

[0054] combine Figure 1-12 As shown, a fully automatic shower curtain keyhole device comprises.

[0055] Further, as a kind of preferred embodiment, comprise frame, frame comprises material rack 1, receiving frame 4, keyhole sewing machine 5 frame 3, workbench 8 and main frame 2; 1 is detachably connected; the other end of the main frame 2 is detachably connected with the receiving rack 4; the two sides of the main frame 2 are respectively provided with a number of keyhole sewing machines 5 frames 3, and the bottom of the main frame 2 is provided with a workbench 8, the main frame 2. The top is composed of several installation beams 6;

[0056] Both sides of 8 workbenches are respectively symmetrically provided with several work areas 36, and each work area 36 corresponds to a keyhole sewing machine 5 frame 3; a keyhole sewing machine 5 is installed on each sewing machine frame;

[0057] Feeding device 7: The feeding device 7 is installed on the main frame 2. The feeding de...

Embodiment 2

[0083] An information management system for a fully automatic shower curtain keyhole device, including the above-mentioned fully automatic shower curtain keyhole device, and also includes: S1, start-up, electrical initialization: return the motor, cylinder and keyhole machine to the set standby position;

[0084] S2. Program setting: set the keyhole distance and the number of keyholes, set the number A of keyholes, set the distance B between adjacent keyholes and set the distance C of the specified position;

[0085] S3, feeding: pick up the cloth and place them in the feeding fixture device 10 respectively, click the start button to complete the feeding action;

[0086] S4. The first stepping mechanism 11 drives the feeding jig device 10 to the position set by the first eye, and the deviation adjustment cylinder in the feeding jig device 10 and the deviation adjustment cylinder of the feeding jig itself start to press down to adjust the deviation. Then the two sewing machines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com