Preparing method for amino-terminated polyurethane for improving tenacity of cured epoxy material

A technology of amino-terminated polyurethane and cured product, which is applied in the field of preparation of amino-terminated polyurethane, can solve the problems of low flexibility, unclear preparation method, weak generalization, etc., and achieves reasonable molecular weight distribution, uniform molecular chain and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

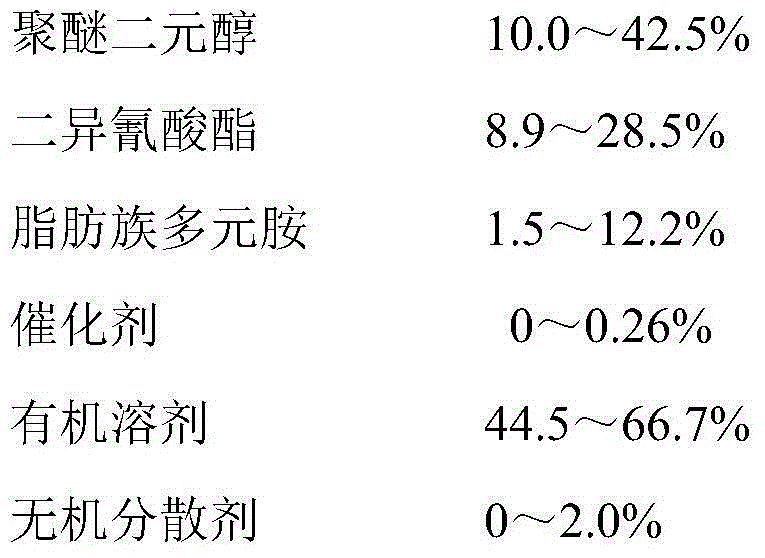

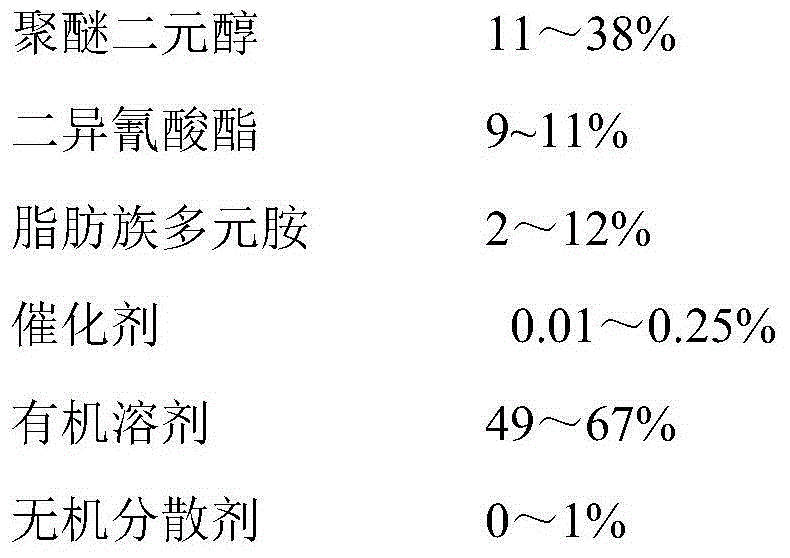

Method used

Image

Examples

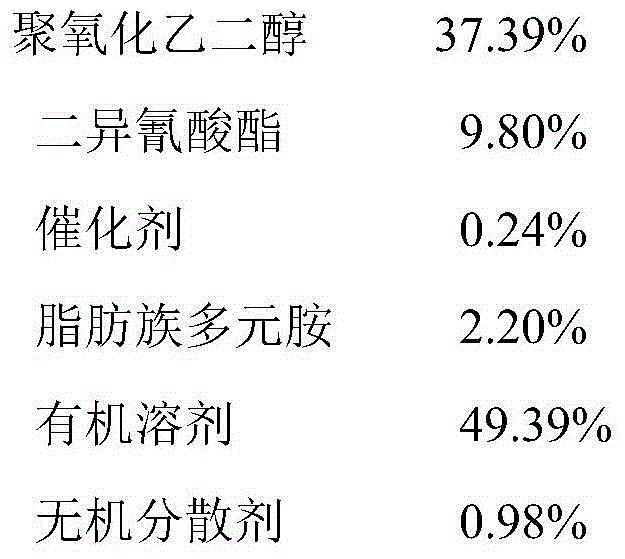

Embodiment 1

[0025] (1) Polyoxyethylene glycol with an average molecular weight of 1000 and TDI are reacted for 3 hours at 60° C. in the presence of a catalyst through nitrogen and deoxygenation; the catalyst is dibutyltin dilaurate;

[0026] (2) Cool down and add THF solvent and a small amount of sodium metaphosphate to dilute the prepolymer system to a certain viscosity;

[0027] (3) The diluted polyurethane prepolymer solution is slowly added to the ethylenediamine-ethyl acetate solution with a weight concentration of 25% through an atomizing spray head, and kept below 10°C to control the temperature change caused by the violent reaction. Lift;

[0028] (4) After the polyurethane prepolymer solution is added, the temperature is raised to 50°C at a heating rate of 2°C / min and kept for 2 hours;

[0029] (5) Tetrahydrofuran, ethyl acetate solvent, and excess monomer in the system are removed under reduced pressure, and sodium metaphosphate is filtered off to obtain the product;

[0030] ...

Embodiment 2

[0034] (1) In the presence of a catalyst, polyoxypropylene glycol with an average molecular weight of 400 and HDI was passed through nitrogen to remove oxygen, and reacted at 40°C for 1.5 hours; the catalyst was a composite catalyst of stannous octoate and dibutyltin dilaurate, with a ratio of 4:6;

[0035] (2) Cool down and add toluene solvent to dilute the prepolymer system to a certain viscosity;

[0036] (3) The diluted polyurethane prepolymer solution is slowly added to the tetraethylenepentamine-ethyl acetate solution with a weight concentration of 40% through the atomizing spray head, and kept below 5°C to control the temperature caused by the violent reaction surge;

[0037] (4) After the polyurethane prepolymer solution is added, the temperature is raised to 40°C at a heating rate of 1°C / min and kept for 2 hours;

[0038] (5) Toluene, ethyl acetate solvent, and excess monomer in the system are removed under reduced pressure to obtain a viscous amino-terminated polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com