A kind of small hollow container blow molding material and preparation method thereof

A small hollow, raw material technology, applied in the field of blow molding plastics, can solve the problems of reduced rigidity and insufficient hardness of blow molding containers, and achieve the effect of satisfying processing performance and various physical and mechanical properties, stable supply, and good anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

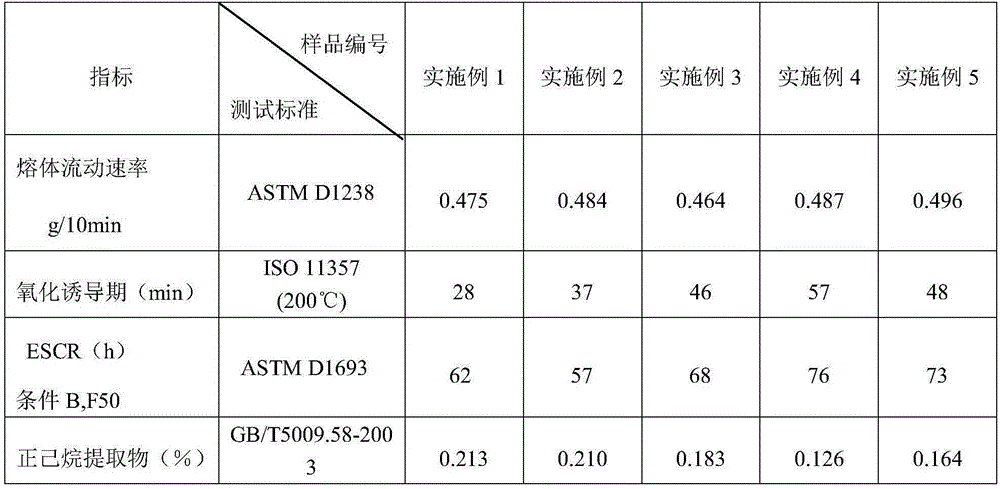

Examples

Embodiment 1

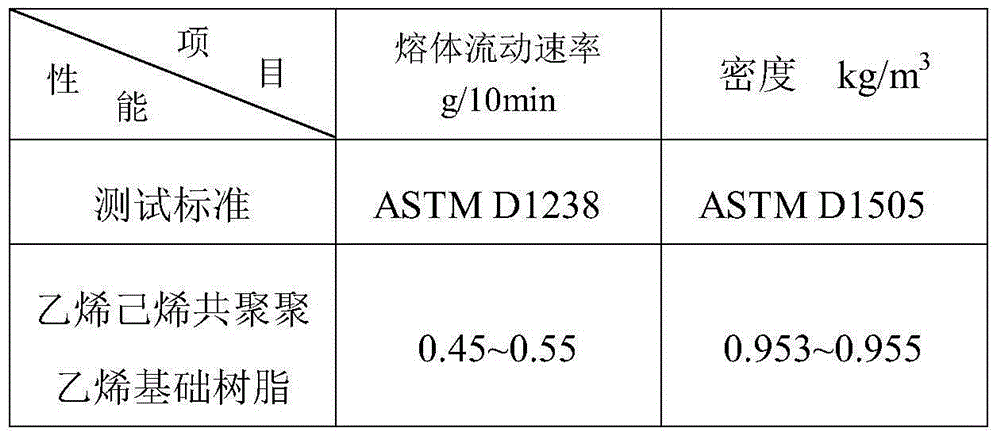

[0043] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0044] The raw materials for the production of base resins are the following substances:

[0045] 1) The feed rate of polymer grade ethylene is 43 tons / hour

[0046] Item Purity % Water Content 10 -6 CO content10 -6 o 2 Content 10 -6

[0047] Index≥99.2≤1≤1≤2

[0048] 2) Catalyst: 969MPI-788-RCP3 of GRACE company, the addition amount is 220kg / hour

[0049] 3) The amount of 1-hexene added is 195kg / hour

[0050] Item Purity % Water Content 10 -6 CO content10 -6 Isomerized alpha olefins

[0051] Index≥98.5≤20≤5≤1%

[0053] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0054] The diluent isobutane is always in a circulating state, inject ethylene and 1-hexene into the loop reactor respectively, strictly control the feeding ratio of ethylene and 1-hexene, and add a pre-activated catalyst to control the The reaction temper...

Embodiment 2

[0065] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0066] The raw materials for the production of base resins are the following substances:

[0067] 1) The feed rate of polymer grade ethylene is 40 tons / hour

[0068] Item Purity % Water Content 10 -6 CO content10 -6 o 2 Content 10 -6

[0069] Index≥99.2≤1≤1≤2

[0070] 2) Catalyst; 969MPI-788-RCP3 of GRACE company, add-on 200kg / hour

[0071] 3) The amount of 1-hexene added is 180kg / hour

[0072] Item Purity % Water Content 10 -6 CO content10 -6 Isomerized alpha olefins

[0073] Index≥98.5≤20≤5≤1%

[0074] 4) An appropriate amount of diluent isobutane.

[0075] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0076] The diluent isobutane is always in a circulating state, inject ethylene and hexene into the loop reactor respectively, strictly control the feed ratio of ethylene and hexene, and add a pre-activated catalyst, and control the reaction tempe...

Embodiment 3

[0085] Raw materials for ethylene-hexene copolymerized polyethylene base resin:

[0086] The raw materials for the production of base resins are the following substances:

[0087] 1) The feed rate of polymer grade ethylene is 38 tons / hour

[0088] Item Purity % Water Content 10 -6 CO content10 -6 o 2 Content 10 -6

[0089] Index≥99.2≤1≤1≤2

[0090] 2) Catalyst: 969MPI-788-RCP3 from GRACE company, the addition amount is 200kg / hour

[0091] 3) The amount of 1-hexene added is 210kg / hour

[0092] Item Purity % Water Content 10 -6 CO content10 -6 Isomerized alpha olefins

[0093] Index≥98.5≤20≤5≤1%

[0094] 4) An appropriate amount of diluent isobutane.

[0095] The preparation method of ethylene-hexene copolymerized polyethylene base resin:

[0096] The diluent isobutane is always in a circulating state, inject ethylene and hexene into the loop reactor respectively, strictly control the feed ratio of ethylene and hexene, and add a pre-activated catalyst, and control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com