Method for preparing polysaccharide sulfate by virtue of electrochemical reaction

A technology of sodium alginate diester and electrochemical reaction is applied in the field of preparing sodium alginate diester by electrochemical reaction, which can solve the problems of screening, complicated process, low purity of intermediates and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The main body of this embodiment is the method for quickly and effectively removing sulfate in the PSS bulk drug:

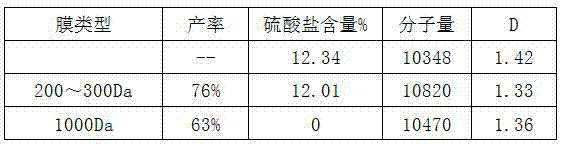

[0010] (1) Experimental procedure: take PSS raw material medicine (tablet raw material medicine, batch number: 0801121, SO 4 2- =12.34%) 100g, dissolved in 2L water (solution concentration 5%), poured the solution into the ultrafiltration and nanofiltration roll-type membrane system, and carried out experiments with 200-300 Da nanofiltration membrane and 1000 Da ultrafiltration membrane respectively. Add 4L of water each time, add water repeatedly to concentrate until the conductivity becomes about 10, concentrate the filtrate to 2L, pour it out, wash the sample on the filter membrane with water, and combine it with the concentrated solution, spray the filtrate to dry, weigh The mass of the sample obtained was used to calculate the yield, and the sulfate content and molecular weight were determined.

[0011] (2) Experimental results and discussion:

[0...

Embodiment 2

[0018] The main body of this embodiment is the selection of ultrafiltration conductance in the preparation of PSS bulk drug:

[0019] (1) Experimental steps: Take PSS API (batch number: 0801121, SO 4 2- =12.34%) 100g, dissolved in 2L water (solution concentration 5%), poured the solution into a nanofiltration instrument, and used a 1000 Da ultrafiltration membrane for ultrafiltration desalination, adding 4L water each time, repeatedly adding water to concentrate until the conductivity Change to about 500, start sampling in the range of 500-10 conductance, 100mL each time (every sampling is guaranteed to be concentrated to about 2L), evaporate each sample to dryness, and use ion chromatography (IC) Determine the most suitable ultrafiltration conductance value by measuring its sulfate content with barium chloride colorimetry.

[0020] (2) Experimental results and discussion

[0021] Ultrafiltration conductivity test results

[0022]

[0023] As can be seen from the result...

Embodiment 3

[0025] The present invention will be further described in conjunction with the main process steps of sodium alginate diester, including five processes of raw material emulsification treatment, acidification chain breaking treatment, esterification treatment, sulfonation treatment and salt formation.

[0026] (1) Raw material emulsification treatment: Take 120 g of alginic acid, moisten it with a small amount of water, dissolve it in polyethylene glycol solution, slowly add 2% of Tween 20, Tween 80 (2:4) compound emulsifier, Put it in a colloid mill and grind for 15 minutes, grind it repeatedly three times to make a uniform oil phase, and transfer it to a reaction tank, gradually add purified water, and stir while adding, until an emulsion is finally formed, usually stirring for 30 minutes to obtain the raw material emulsion ;

[0027] (2) Acidification chain breaking treatment: put the raw material emulsion into the reaction kettle, add 1000 ml of 0.6 mol / L hydrochloric acid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com