Synthetic method of nitrogen-containing flame-retardant phenolic resin

A technology of phenolic resin and synthesis method, which is applied in the field of preparation of modified phenolic resin, can solve problems such as increased process complexity, cumbersome process, and influence on product electrical properties, and achieves the effects of reasonable molecular weight distribution, simple operation, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

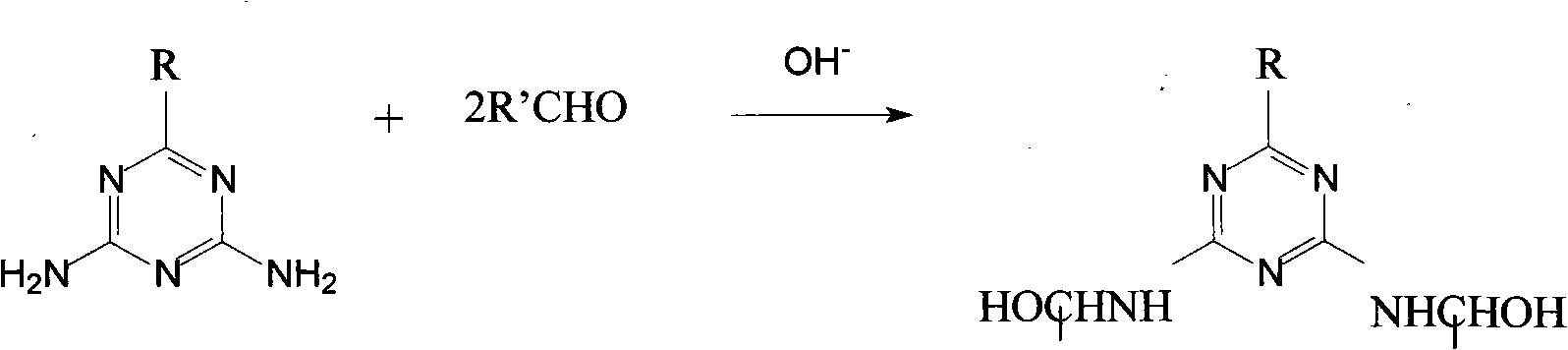

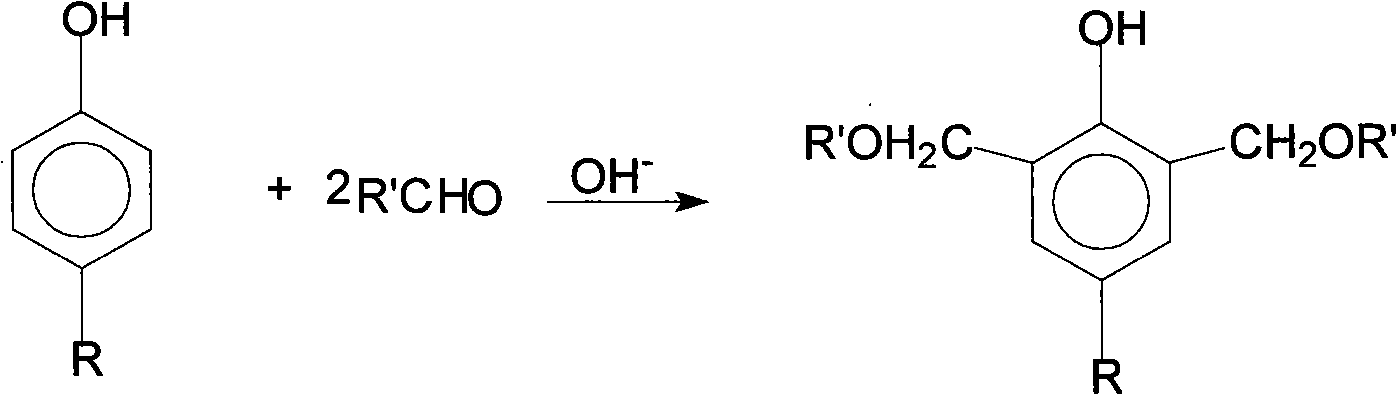

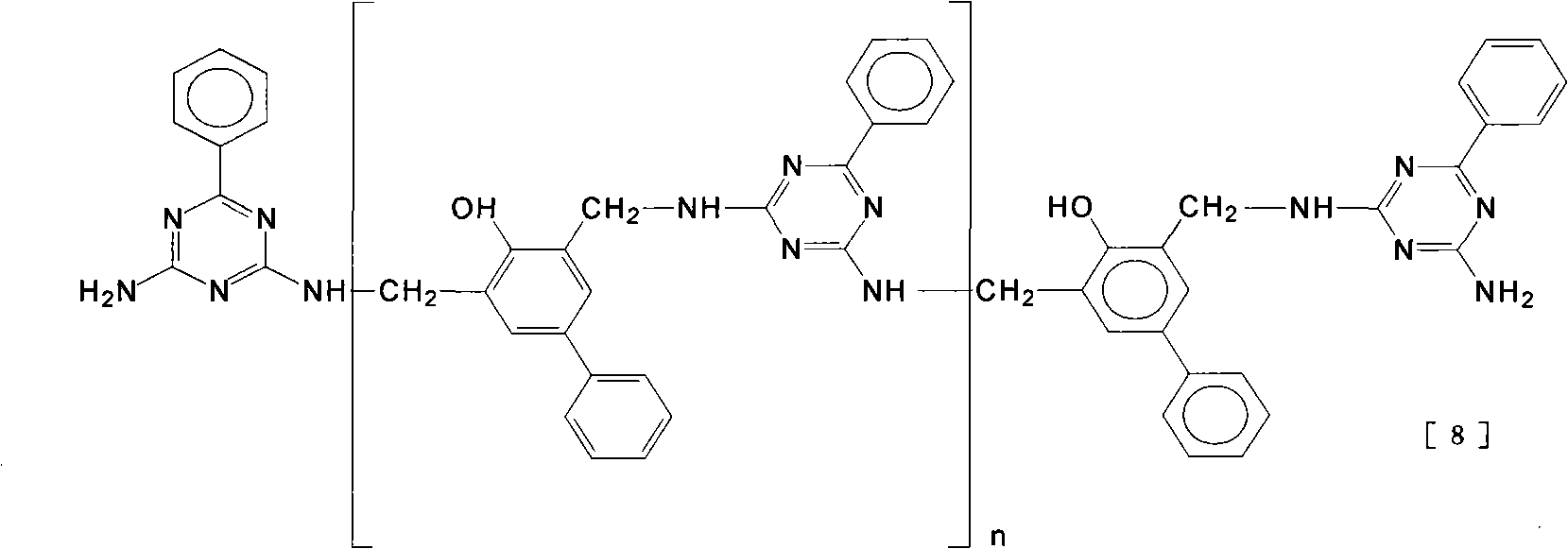

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Methylmelamine / formaldehyde / guanidine carbonate / p-phenylphenol prepares nitrogen-containing flame-retardant phenolic resin

[0035] In a 1000ml three-necked flask equipped with stirring, take by weighing 140 grams of methyl melamine by weight, 100 grams by weight of 100 wt% acetaldehyde solution, add 250 g of water and stir evenly, then adjust the pH of the solution with 15 wt % guanidine carbonate aqueous solution The value is 8.5, the temperature is raised to 70°C, and the temperature is maintained at 70-75°C for 40 minutes. Subsequently, add 108 gram parts by weight of p-cresol and 120 gram parts by weight of 100wt% acetaldehyde solution, adjust the pH value of the solution to 9.0 with 15wt% guanidine carbonate aqueous solution, heat up to 70°C, keep the temperature at 70~75°C React for 40 minutes. Continue to use 15wt% guanidine carbonate aqueous solution to adjust the pH of the solution to 9.5, raise the temperature to 80° C., and keep the temperatur...

Embodiment 2

[0037] Embodiment 2: Methylmelamine / formaldehyde / guanidine carbonate / p-phenylphenol prepares nitrogen-containing flame-retardant phenolic resin

[0038] In the 1000ml there-necked flask with stirring, take by weighing the methyl melamine of 140 gram parts by weight, the 37wt% formaldehyde solution of 240 gram parts by weight, after stirring evenly, adjust the pH value of solution with 10wt% guanidine carbonate aqueous solution to be 10.0, Raise the temperature to 65°C and keep the temperature between 65°C and 70°C for 60 minutes. Add the phenylphenol of 170 grams by weight and the 37wt% formaldehyde of 260 grams by weight, adjust the pH value of the solution with 20wt% guanidine carbonate aqueous solution to be 9.5, heat up to 75°C, keep the temperature between 75~80°C for reaction 80 minutes. The pH value of the solution was adjusted to 9.5 with 15 wt % guanidine carbonate aqueous solution, the temperature was raised to 85° C., and the temperature was kept between 85° C. and 9...

Embodiment 3

[0040] Embodiment 3: Preparation of nitrogen-containing flame-retardant phenolic resin by benzomelamine / formaldehyde / aminoguanidine / p-phenylphenol

[0041] In the 1000ml there-necked flask that is equipped with stirring, take by weighing the benzomelamine of 187 gram parts by weight, the 37wt% formaldehyde aqueous solution of 200 gram parts by weight, after stirring evenly, adjust the pH value of solution with 10wt% aminoguanidine aqueous solution to be 10.0, Raise the temperature to 80°C and keep the temperature between 80-85°C for 30 minutes. Add 170 gram parts by weight of p-phenylphenol and 220 gram parts by weight of 37wt% formaldehyde, adjust the pH value of the solution to 10.0 with 10wt% aminoguanidine aqueous solution, heat up to 85°C, and keep the temperature between 85~90°C React for 60 minutes. The pH value of the solution was adjusted to 10.0 with 10 wt % guanidine carbonate aqueous solution, the temperature was raised to 90° C., and the temperature was maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com