Bimodal polyethylene resin for large-caliber thick-wall low-sag pipes and preparation method of bimodal polyethylene resin

A polyethylene resin and large-diameter technology, applied in the field of bimodal polyethylene pipe resin and its preparation, can solve problems such as unreasonable molecular weight distribution, uncontrollable distribution, and post-processing difficulties, so as to achieve reasonable molecular weight distribution and improve mechanical properties , the effect of excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] In the embodiment, the preparation method of bimodal polyethylene composition, concrete steps are as follows:

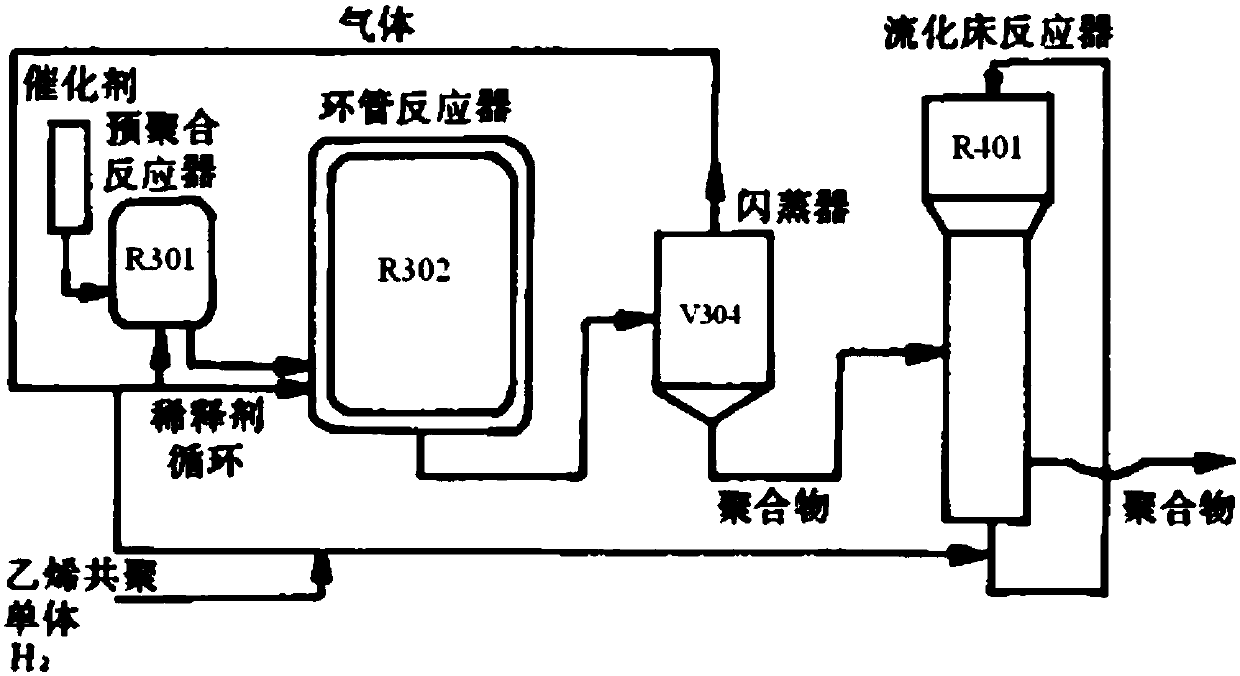

[0018] In step (1), ethylene, hydrogen, and comonomer (alpha olefin) are polymerized by a series reactor method in the presence of a polymerization catalyst to obtain polyethylene powder, and the loop reactor is polymerized to obtain a low molecular weight part, and the fluidized bed reaction The high molecular weight part is obtained by polymerization in the reactor, and the production rate of the two reactors is adjusted to adjust the ratio of the high molecular weight part to the low molecular weight part. The reaction flow chart of the device is as follows figure 1 shown.

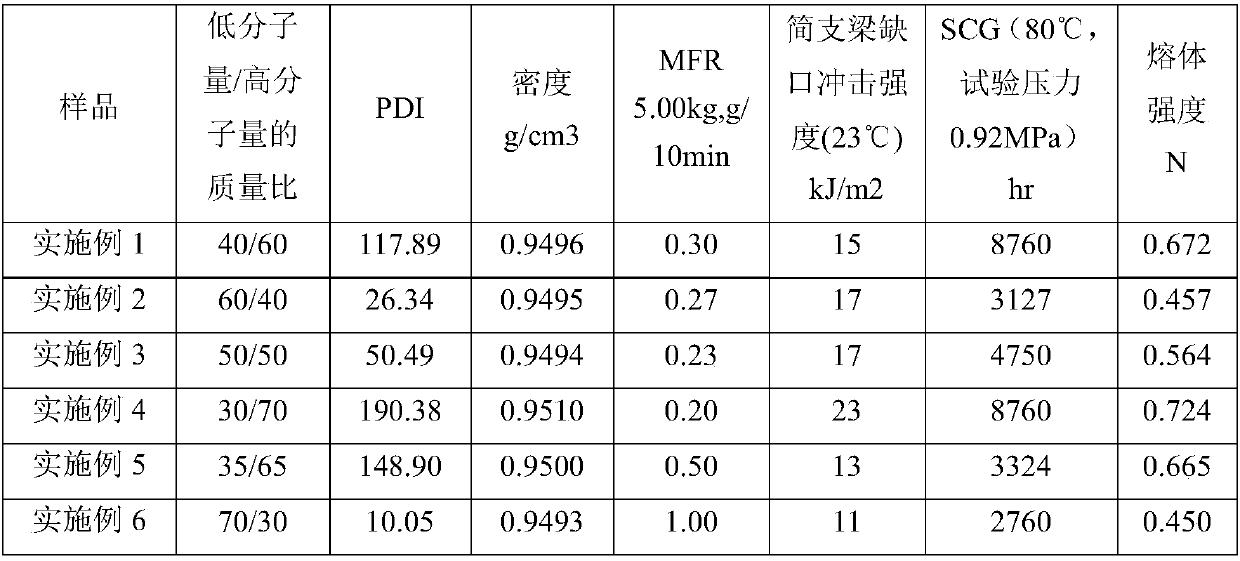

Embodiment 1

[0021] Bimodal polyethylene resin powder, calculated by mass parts, including 100 parts of high-density polyethylene (MFR: 0.30, α-olefin mass content of 0.9, molecular weight distribution of 117.89), 0.05 parts of light stabilizer 2020, 0.1 parts of UV absorber UV328, 0.2 parts of antioxidant 1010 and antioxidant 168 with a weight ratio of 2:1, 5 parts of carbon black masterbatch.

Embodiment 2

[0023] Bimodal polyethylene resin powder, calculated by mass parts, including 100 parts of high-density polyethylene (MFR: 0.27, α-olefin mass content of 0.6, molecular weight distribution of 26.34), 0.05 parts of light stabilizer 2020, 0.1 parts of UV absorber UV328, 0.2 parts of antioxidant 1010 and antioxidant 168 with a weight ratio of 2:1, 5 parts of carbon black masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com