Alkyd resin preparation method and resin prepared by the same, and acrylic acid modified alkyd resin preparation method and resin prepared by the same

An alkyd resin, functional technology, applied in coatings and other directions, can solve problems such as high VOC emissions, lax alcoholysis process control, and impact on paint film quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

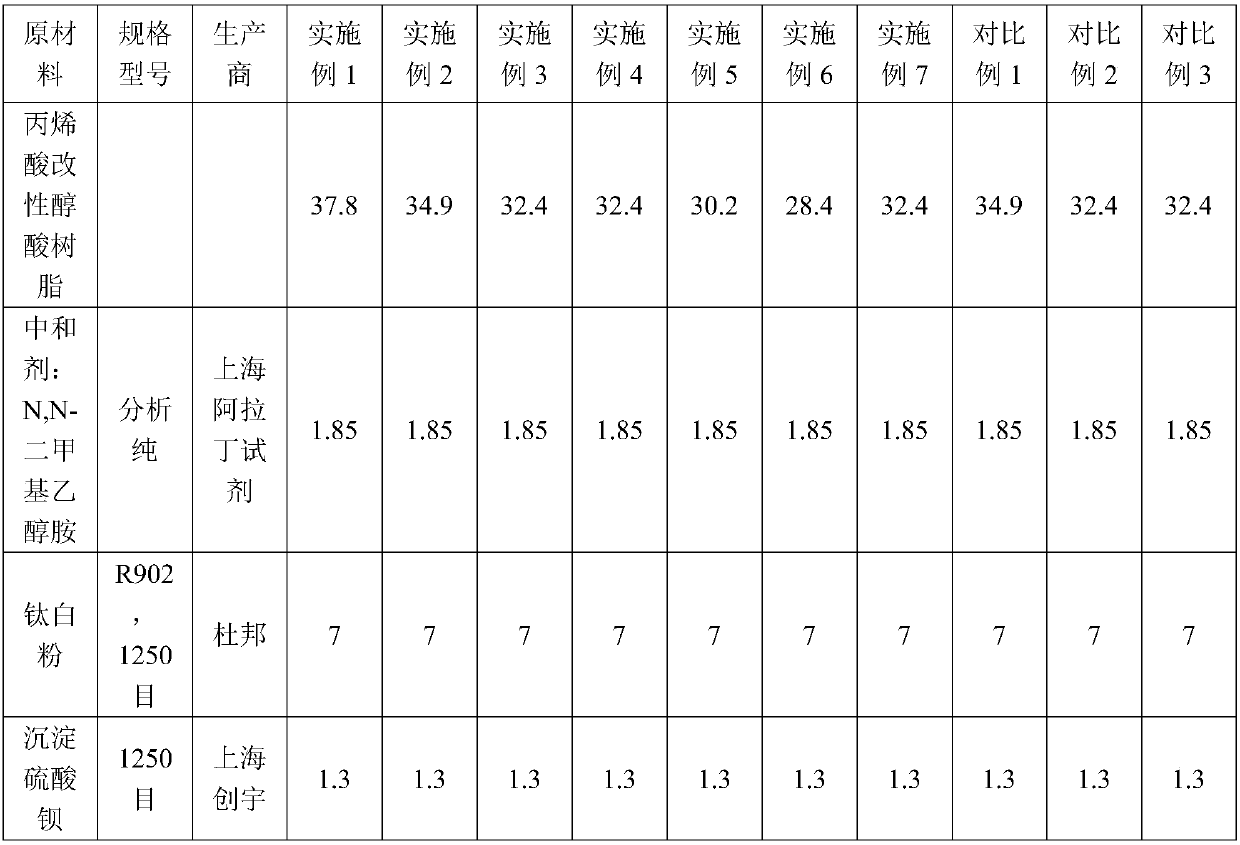

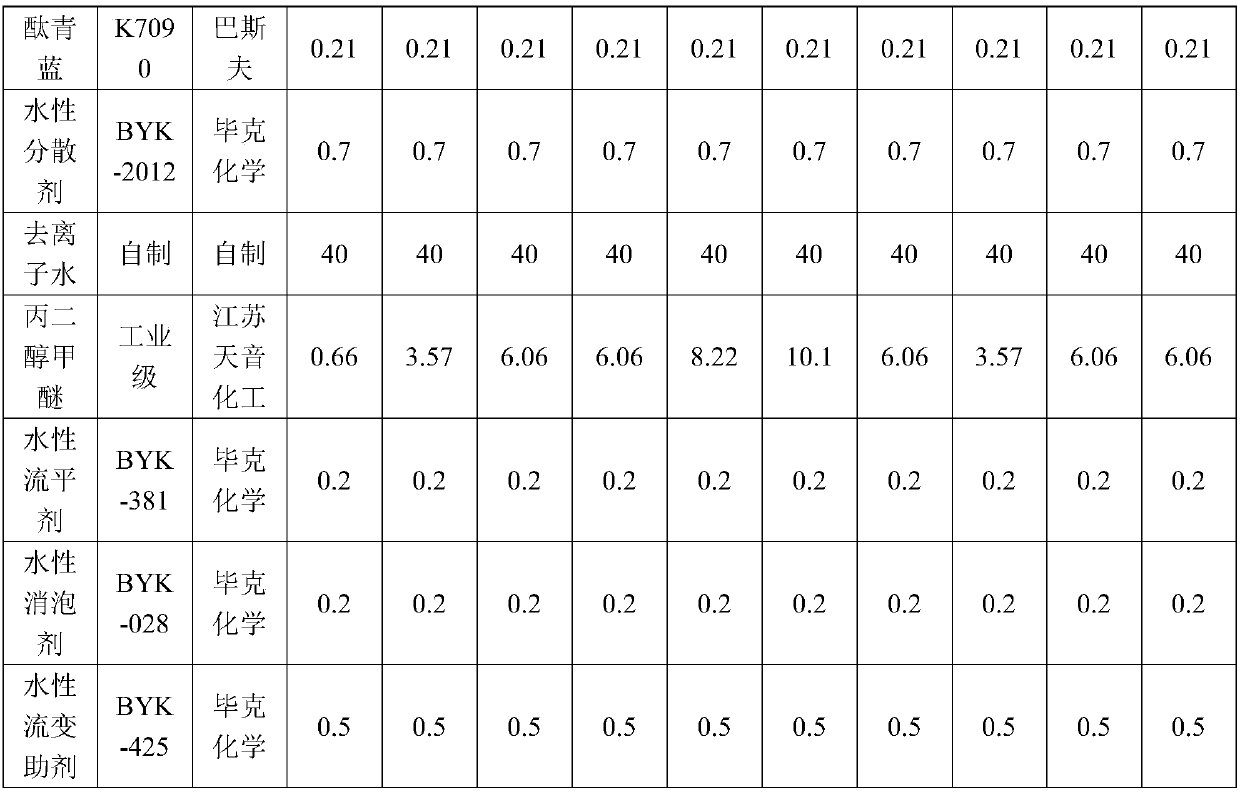

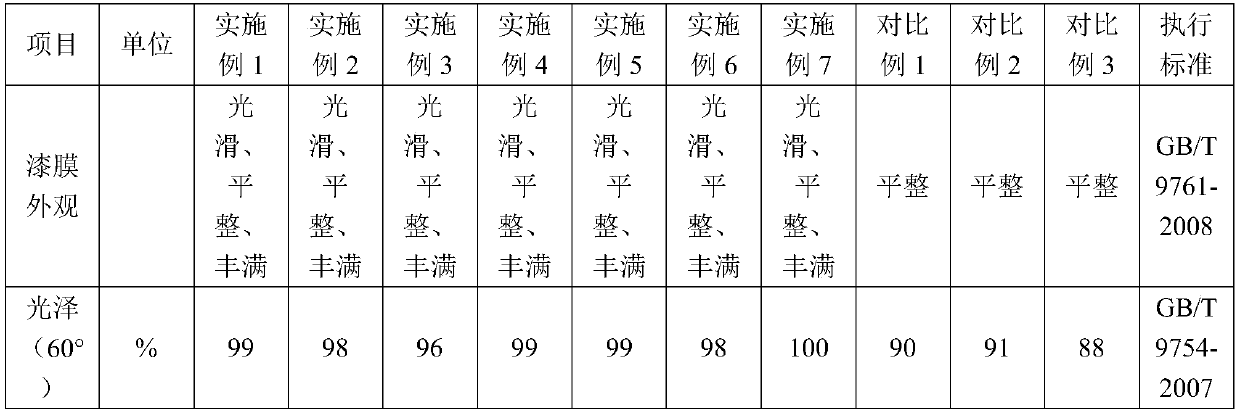

Examples

Embodiment 1

[0102] The tolerance test method of Example 1: Take the sample and methanol in the reactor for testing, mix the sample and methanol at a volume ratio of 1:2 at 25°C and let it stand, when the standing mixture is clear and transparent When the tolerance test is passed.

Embodiment 2

[0103] The tolerance test method of Example 2, Example 5, and Comparative Example 1: Take the sample and methanol in the reactor for testing, mix the sample and methanol at a volume ratio of 1:3 at 25°C and let it stand , when the standing mixture is clear and transparent, the tolerance test is passed.

Embodiment 3

[0104] Example 3, Example 4, Example 6, Comparative Example 2, and Comparative Example 3 Tolerance test method: Take the sample and ethanol in the reactor for testing, and make the sample and ethanol at 25°C at a ratio of 1:5 The volume ratio is fully mixed and allowed to stand. When the standing mixture is clear and transparent, it indicates that the tolerance test has passed.

[0105] Example 1

[0106] The preparation method of alkyd resin is as follows:

[0107] 1. Under a nitrogen atmosphere, put 238g of soybean oil, 349.5g of trimethylolpropane, and 35g of pentaerythritol into the reactor, start stirring, heat up to 220°C, and put in 0.06g of lithium hydroxide for alcoholysis reaction. During the reaction, from Sampling test tolerance in the reactor, if the test is qualified, the alcoholysis reaction is ended; the reaction time used for the alcoholysis reaction is 1.5 hours;

[0108] 2. Control the temperature of the reactor at 180°C, add 353g of phthalic anhydride, 9....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com