Special peptone for producing inosine through fermentation as well as preparation method and application of peptone

A technology of peptone and inosine, which is applied in the field of peptone preparation, can solve the problems of high production cost affecting the large-scale production of inosine, different effects of inosine fermentation level, and high requirements for equipment conditions, so as to prolong the synthesis time of inosine and improve the production efficiency of inosine. Yield, the effect of promoting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

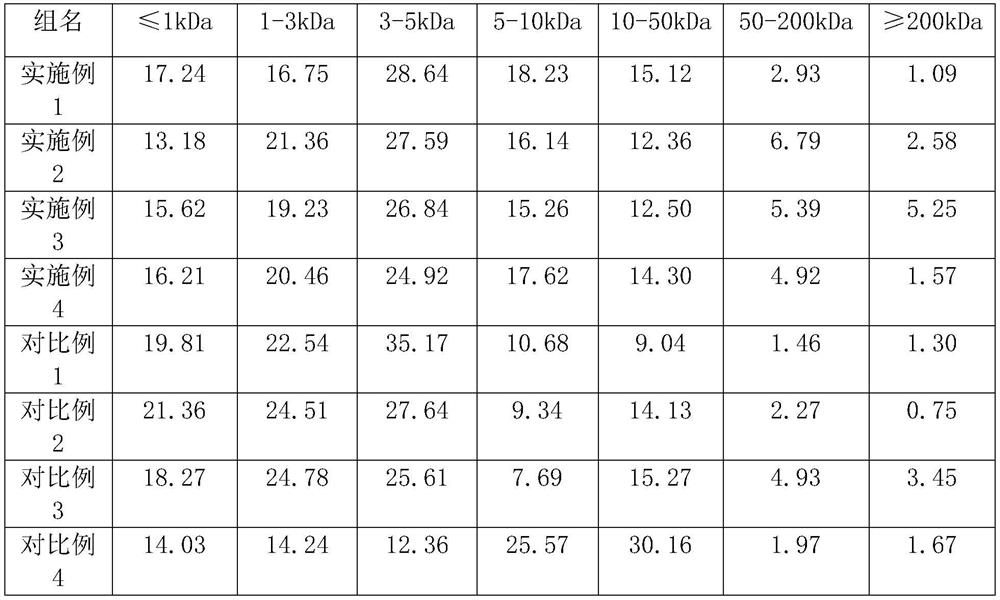

Examples

Embodiment 1

[0029] A preparation method for producing inosine-specific peptone by fermentation, comprising the following steps:

[0030] (1) Take fresh fish bones, add water to cook under high temperature and high pressure (the mass ratio of fresh fish bones to water is 1:6), and keep warm for 1 hour under 3 standard atmospheric pressure. Press the bone broth into the storage tank (the tank's own pressure), pass through the oil-water separator, put the bone broth with the oil layer removed into the enzymolysis tank, adjust the pH value to 7, and the temperature is 50 ° C, add minced fish bones with a total weight of 1‰ Protease, 2‰ of aminopeptidase, 1‰ of neutral protease, stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 15 minutes, stirring for 15 minutes and stopping for ...

Embodiment 2

[0035](1) Take fresh fish bones, add water to cook under high temperature and high pressure (the mass ratio of fresh fish bones to water is 1:6), and keep warm for 1 hour under 3 standard atmospheric pressure. Press the bone broth into the storage tank (the tank's own pressure), pass through the oil-water separator, put the bone broth with the oil layer removed into the enzymolysis tank, adjust the pH value to 7.2, and the temperature is 50°C, add minced fish bones with a total weight of 1‰ Protease, 2‰ of aminopeptidase, 1‰ of neutral protease, stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 15 minutes, stirring for 15 minutes and stopping for 15 minutes. After the enzymatic hydrolysis, add 500mL of acetic acid, then adjust the pH to 5.2 with hydrochloric acid,...

Embodiment 3

[0040] (1) Take fresh fish bones, add water to cook under high temperature and high pressure (the mass ratio of fresh fish bones to water is 1:6), and keep warm for 1 hour under 3 standard atmospheric pressure. Press the bone broth into the storage tank (the tank's own pressure), pass through the oil-water separator, put the bone broth with the oil layer removed into the enzymolysis tank, adjust the pH value to 7.4, and the temperature is 45°C, add minced fish bones with a total weight of 1‰ Protease, 2‰ of aminopeptidase, 1‰ of neutral protease, stirring slowly, stirring for 10 minutes and stopping for 5 minutes, stirring for 10 minutes and stopping for 5 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 10 minutes, stirring for 15 minutes and stopping for 15 minutes, stirring for 15 minutes and stopping for 15 minutes. After enzymatic hydrolysis, add 500mL of acetic acid, then adjust the pH to 5.3 with hydrochloric acid, ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com