Preparation method of polyether ketone/sulfone high-temperature resistant material

A polyether ketone and high temperature resistant technology, applied in the field of high temperature resistant material preparation, can solve problems such as product performance decline, and achieve the effects of improving quality, reducing production cost and reasonable molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

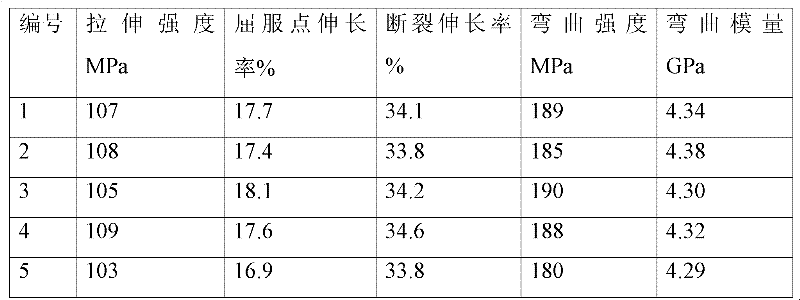

Embodiment 1

[0037] Example 1 Preparation of polyether ether ketone by sulfolane system

[0038]Add 49Kg sulfolane solvent, 3.303Kg hydroquinone, 6.677Kg4,4'-difluorobenzophenone and 3.5Kg anhydrous sodium carbonate in the first reaction kettle made of 50L enamel, take hot water as heating medium at 90 Under the condition of ℃, after mixing for 30 minutes with a propulsive enamel stirring paddle at a speed of 200 r / min, after all the monomers were dissolved, a mixed material with a viscosity of 38 mPa·S was obtained. Transfer the mixed material to the second reaction kettle made of 50L enamel, use 200°C heat conduction oil as the heating medium, stir with a plate and frame paddle stirrer coated with polytetrafluoroethylene at 150 rpm, and use 2.5L xylene as the After the water-carrying agent is fully water-carrying, the material with a viscosity of 127mPa·S is obtained, and the material is put into the third reaction kettle made of 50L stainless steel, and the heat transfer oil is used as ...

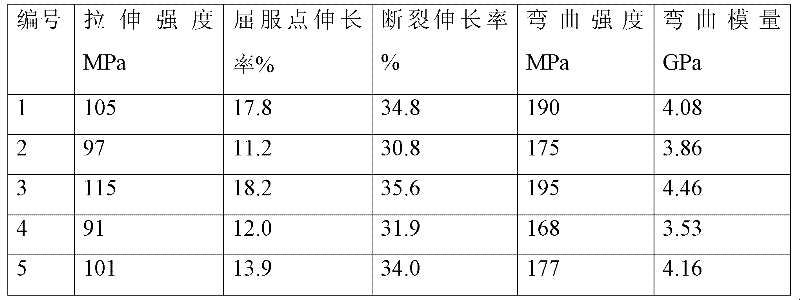

Embodiment 2 2

[0045] Example 2 Preparation of polyether ether ketone ketone by diphenyl sulfone system

[0046] Add 35.49Kg diphenylsulfone, 7.497Kg4, 4'-dihydroxybenzophenone, 7.713Kg4, 4'-difluorobenzophenone and 3.9Kg anhydrous sodium carbonate in the first reaction kettle made of 50L enamel, Water vapor at 160°C was used as the heating medium to feed into the inner coil of the kettle, and a flat-bladed enamel stirring paddle was used to mix at a speed of 180 rpm for 30 minutes until the monomers were completely dissolved, and a mixed material with a viscosity of 44mPa·S was obtained. Transfer the mixed materials into the second reaction kettle made of 50L stainless steel, use heat conduction oil at 220°C as the heating medium, stir with a PTFE-coated inclined-blade paddle stirrer at 120 rpm, and use high-purity nitrogen as protection After the gas and the generated water are taken out to a certain extent, the material enters another 50L stainless steel second reaction kettle to continue...

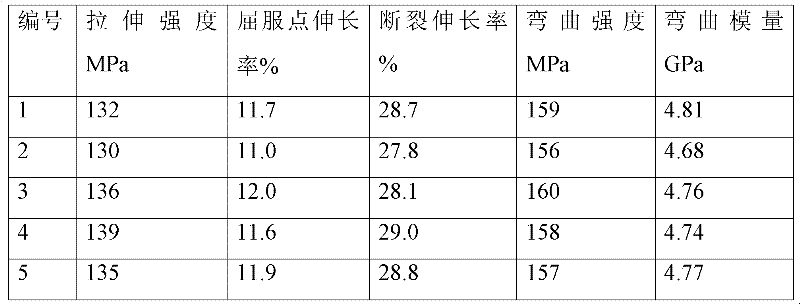

Embodiment 3 2

[0053] Example 3 Preparation of polyether ether ketone by diphenyl sulfone system

[0054] Add 40Kg of diphenyl sulfone solvent, 6.606Kg of hydroquinone, 13.354Kg of 4,4'-difluorobenzophenone and 7.0Kg of anhydrous sodium carbonate into the first reaction kettle made of 50L enamel, and use hot water as the heating medium Under the condition of 120°C, after mixing for 30 minutes with a propulsive enamel stirring paddle at a speed of 200 rpm, after all the monomers were dissolved, a mixed material with a viscosity of 52 mPa·S was obtained. Transfer the mixed material into the second reaction kettle made of 50L enamel, use heat conduction oil at 260°C as the heating medium, stir with a plate-and-frame paddle stirrer coated with polytetrafluoroethylene at 150 rpm, and use 2.5L xylene as the heating medium. After the water-carrying agent and water are completely carried out, the material with a viscosity of 850mPa·S is obtained, and the material is put into the third reaction kettl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com