A Strip Wet Filling and Roofing Mining Method

A technology of wet filling and mining method, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problem of unsuitable mining of phosphate rock, and achieve the effect of ensuring economic feasibility, improving safety factor, and reducing the amount of cemented filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

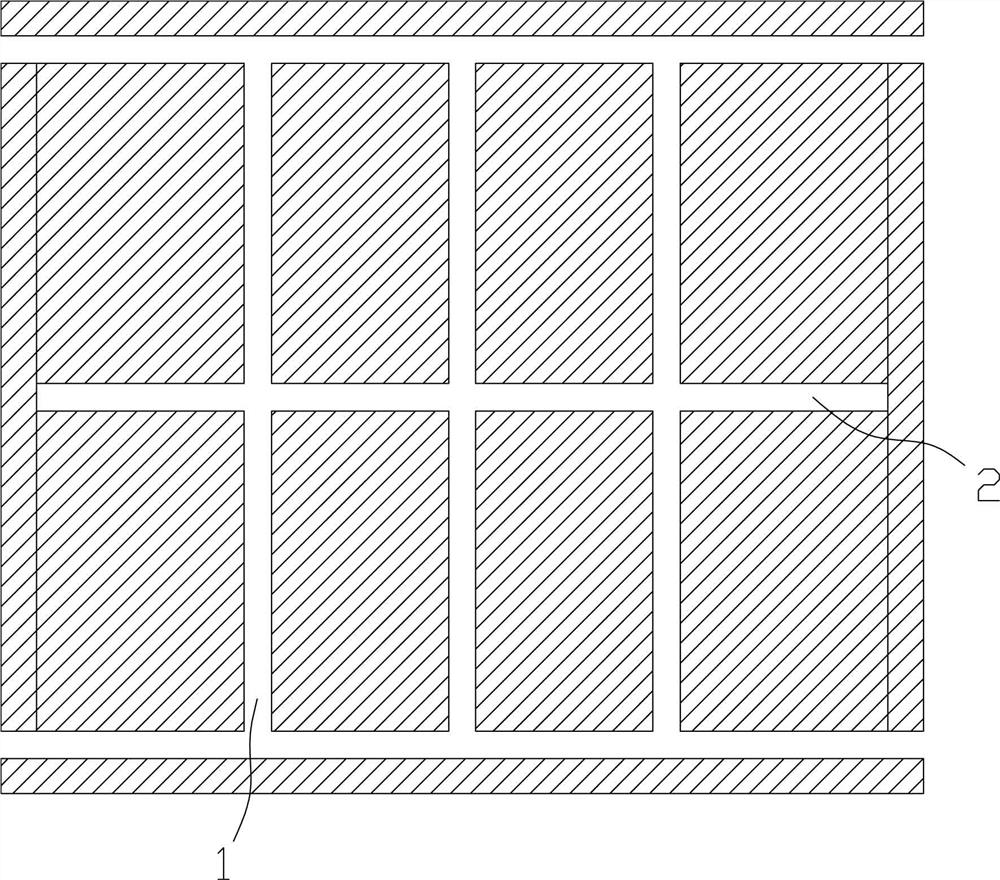

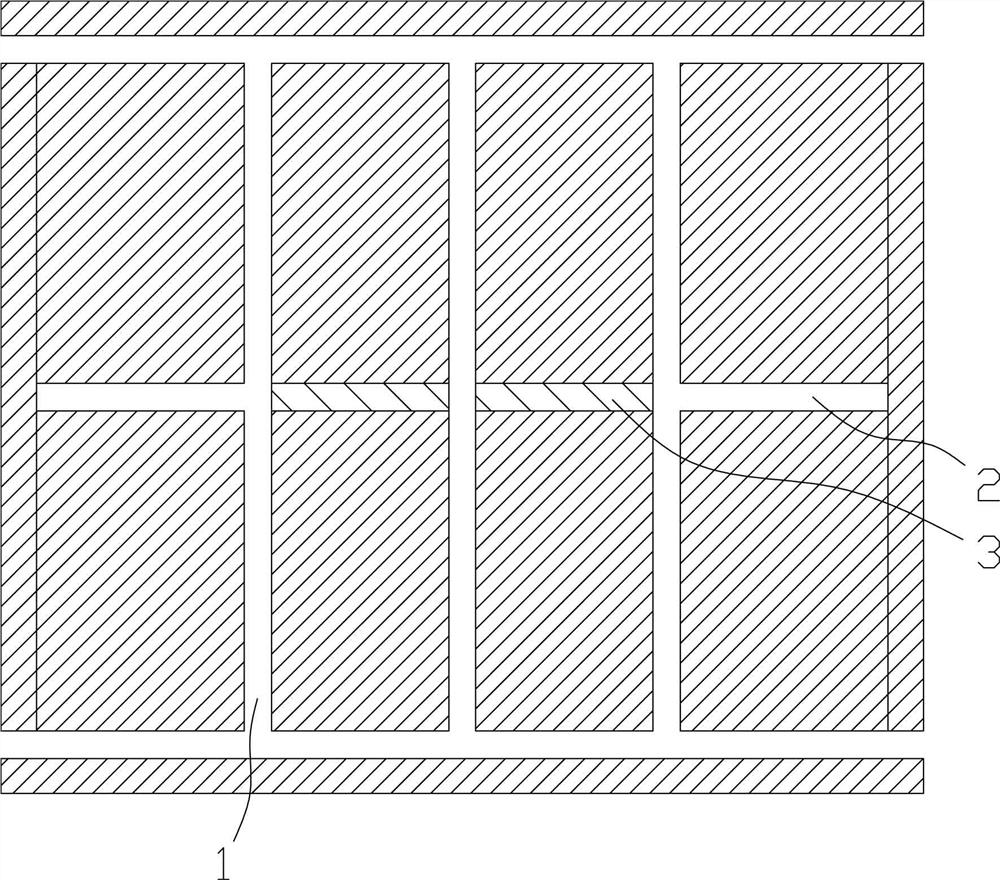

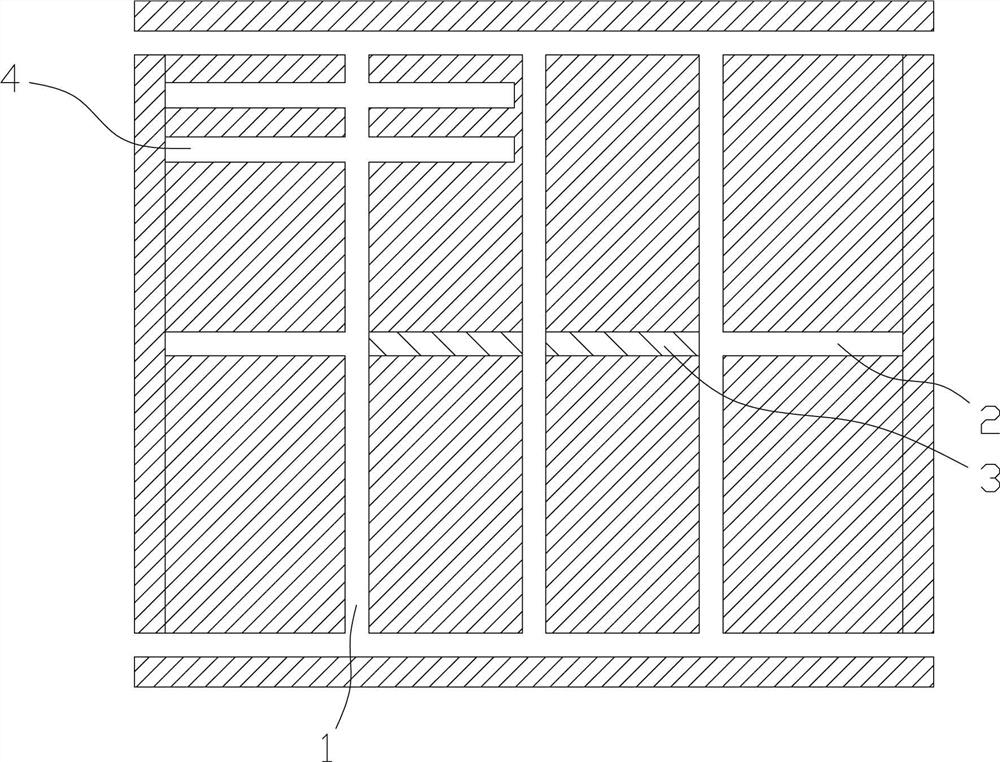

Image

Examples

Embodiment 2

[0041] On the basis of Embodiment 1, in step 1), the distance between two adjacent segmented roadways 2 is not greater than 50 meters. The distance between the sub-section roadways 2 is controlled to be no more than 50 meters to achieve the purpose of controlling the distance between the filling material unloading site 3 and the working surface, reducing the filling material transfer distance, and improving the filling efficiency.

Embodiment 3

[0043] On the basis of Example 1, in step 3), the two ends of the first bottom-drawing roadway 4 respectively extend into two adjacent excavation units, and both ends of the first bottom-drawing roadway 4 do not penetrate through, wherein A 1.5m rear pillar is left at one end. The non-penetrating method is used to construct the bottom roadway, which avoids the pouring of retaining walls, reduces the amount of cemented filling, and improves the filling efficiency.

[0044] In a preferred solution, the length of the columns 6 between the two strips is controlled to be 30-40 meters, and the width is controlled to be 3-3.5 meters.

[0045] The bottom-drawing roadway is 3-3.5 meters wide, which controls the filling volume of the wet strip, reduces the bottom filling cost, and ensures the economic feasibility of the filling mining plan; it is 30-40 meters long to ensure the filling efficiency, and at the same time controls the 6 columns between the strips The recovery period ensure...

Embodiment 4

[0047] On the basis of Example 1, the strip column 6 between the second first bottom-drawing roadway 4 and the third first bottom-drawing roadway 4 is mined and runs through the mine house to form a safety exit without backfilling. In this way, the safety exit is continuously advanced with the advancement of mining, and it is always ensured that the safety exit does not exceed three rows of ore pillars in the mining area, and the safety factor of the safety exit is improved.

[0048] In this application, the raw materials for the wet filling material are the waste rock produced in the shaft, the tailings of the ore dressing plant and the machine-made sand as the main aggregates. The raw materials are cheap and the solid waste can be reused. With 100kg cement per cubic meter, the comprehensive strength of the filling body is 4-6MP, and the comprehensive filling cost is 100-120 yuan / m 3 .

[0049] The filling process adopts the filling process of mixing on the ground, truck tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com