Self-weight-based uniform filling device for sewage treatment agent production

A sewage treatment agent and filling device technology, which is applied in liquid treatment, packaging, bottle filling, etc., can solve the problems of treatment agent leakage, poor filling accuracy, and high use limitations, so as to improve the filling effect and reduce the Small impact force, the effect of improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

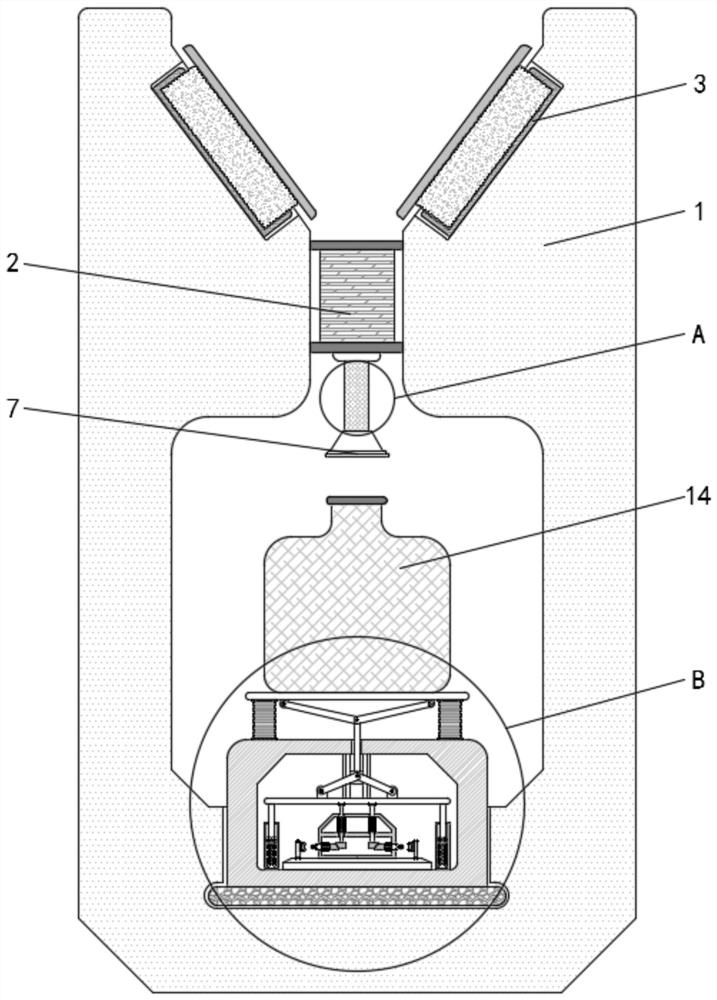

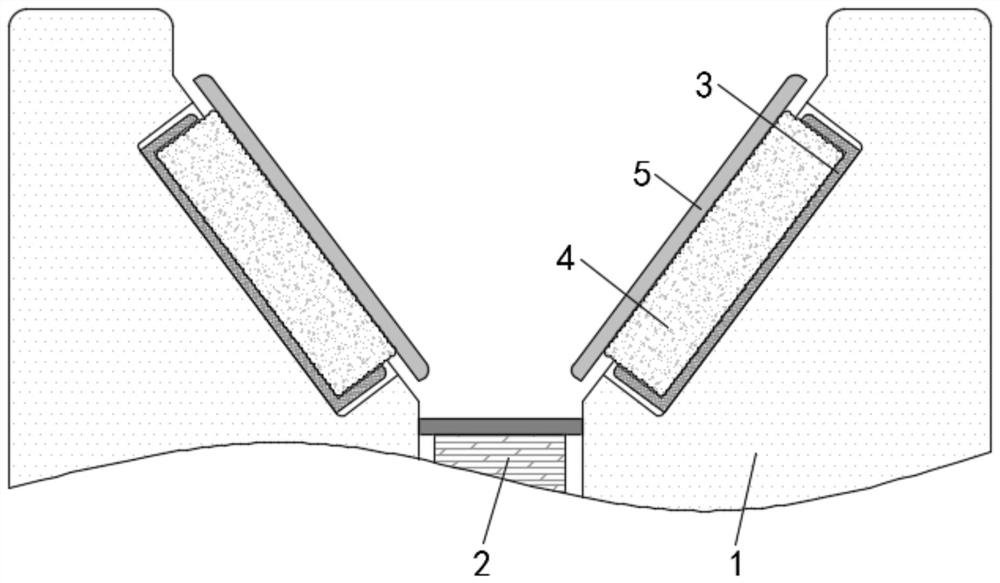

[0025] as attached figure 1 To attach Figure 5 Shown:

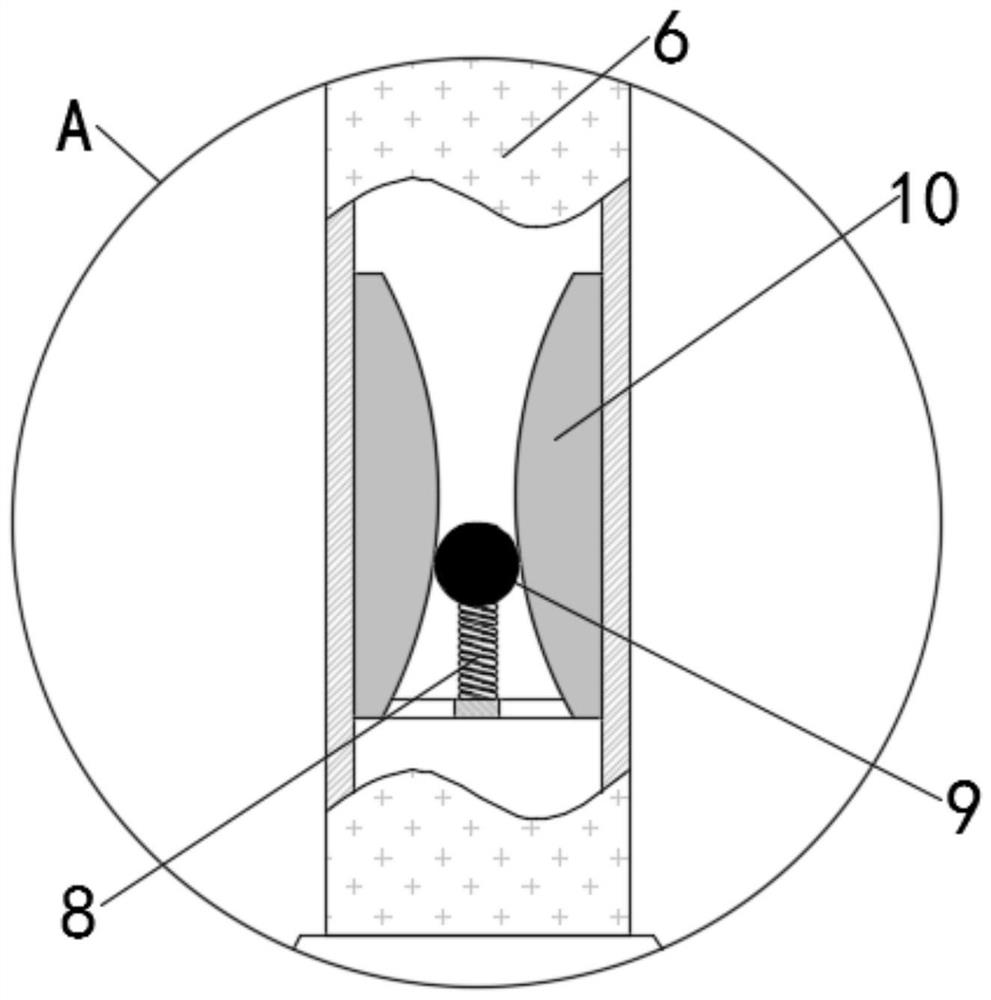

[0026] The invention provides a self-weight-based uniform filling device for the production of sewage treatment agents, which includes a housing 1, a filling device 2 is installed on the upper side of the housing 1, and a shock-absorbing air bag 4 is installed inside the buffer device 3. The outer side of the shock-absorbing airbag 4 is provided with a shock-absorbing plate 5, and the effective installation of the shock-absorbing airbag 4 and the shock-absorbing plate 5 can reduce the impact force when the treatment agent is fed downward, thereby improving the practicality of the equipment. performance, the inside of the housing 1 is embedded with a buffer device 3, the lower side of the filling device 2 is installed with a filling pipe 6, and the inside of the filling pipe 6 is installed with a spring mechanism 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com