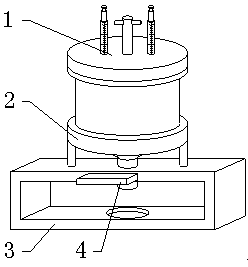

Filling equipment for honey processing and production

A filling equipment, honey technology, applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as poor filling effect and control of honey stirring and filling volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

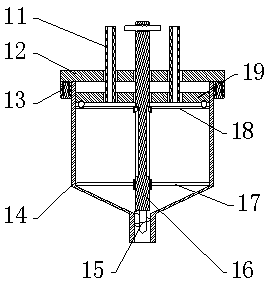

[0020] Specific implementation method: in actual use, the user turns the locking bolt to separate the cover plate 12 from the fixed ring 13, and then the user removes the sealing floating plate 19 from the inside of the storage tank 14, and then the user puts the The honey is poured into the storage tank 14, and when the honey is poured into the designated position, the user puts the sealing floating plate 19 into the storage tank 14 again, and uses locking bolts to fasten the cover plate 12 to the fixed ring 13 the upper end surface, and then the user pulls the injection barrel to vacuumize the honey inside the storage tank 14, and then the user places the empty honey bottle in the middle of the lower end surface of the frame 3, and aligns the mouth of the bottle with the storage tank 14 end face, and then the user pulls the baffle plate 4 outwards, thereby opening the lower end face of the storage tank 14, and then the user turns the handle bar, thereby driving the rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com