BB pill forming device

A technology of projectiles and forming grooves, which is applied in the field of BB projectile forming devices, can solve problems such as poor roundness, influence on accuracy, and reduce service life of forming molds, so as to improve roundness, ensure pass rate, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

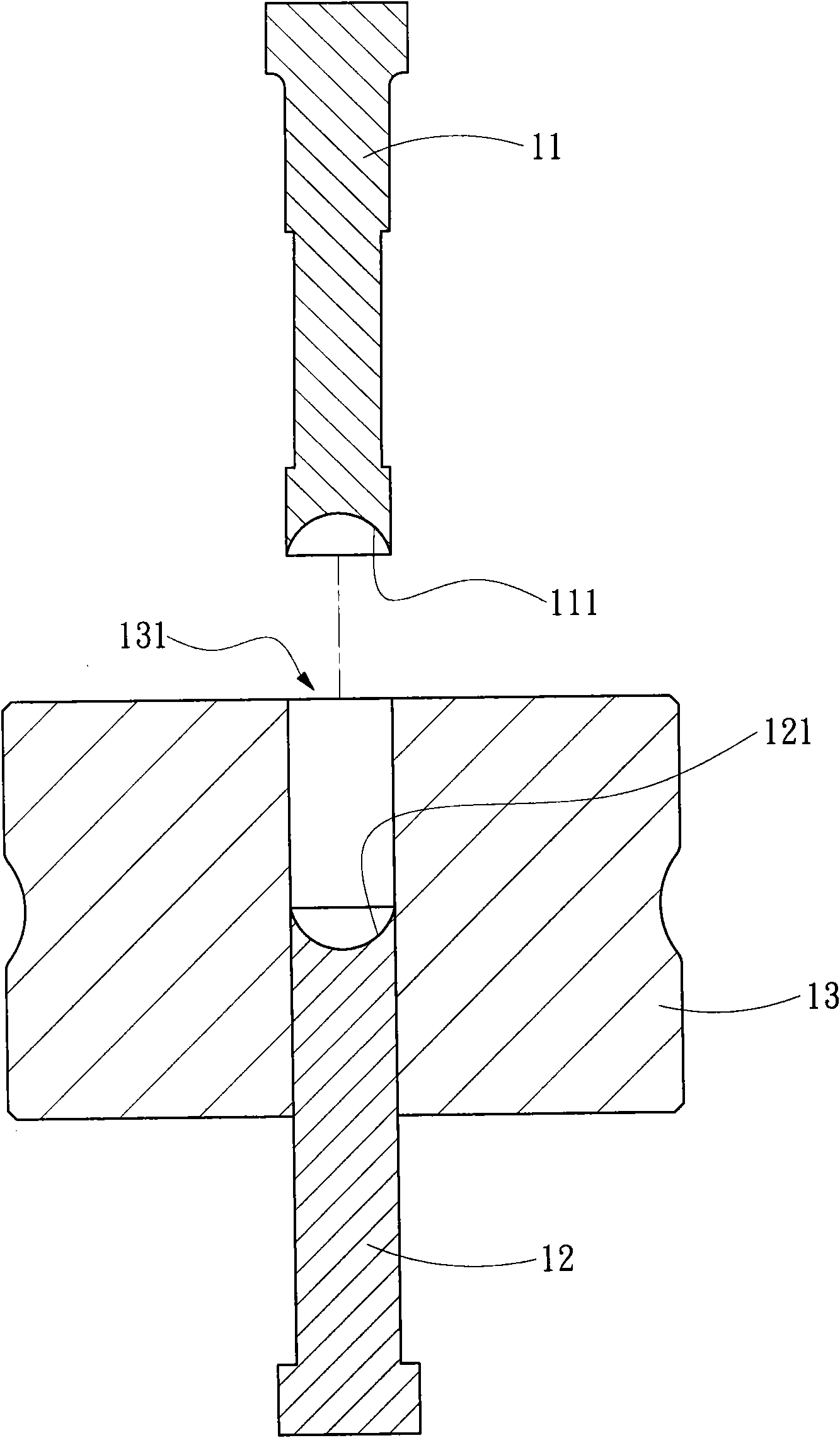

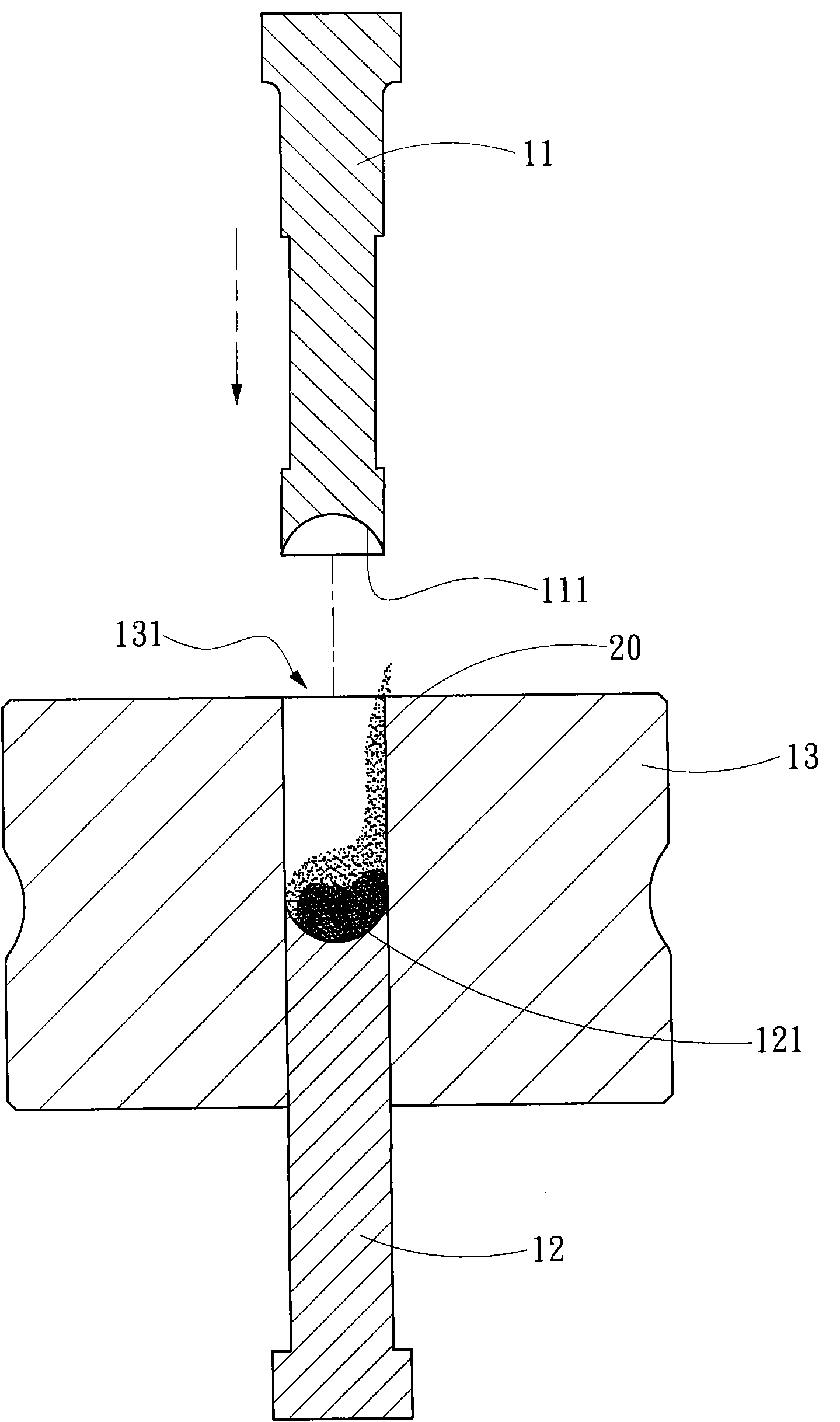

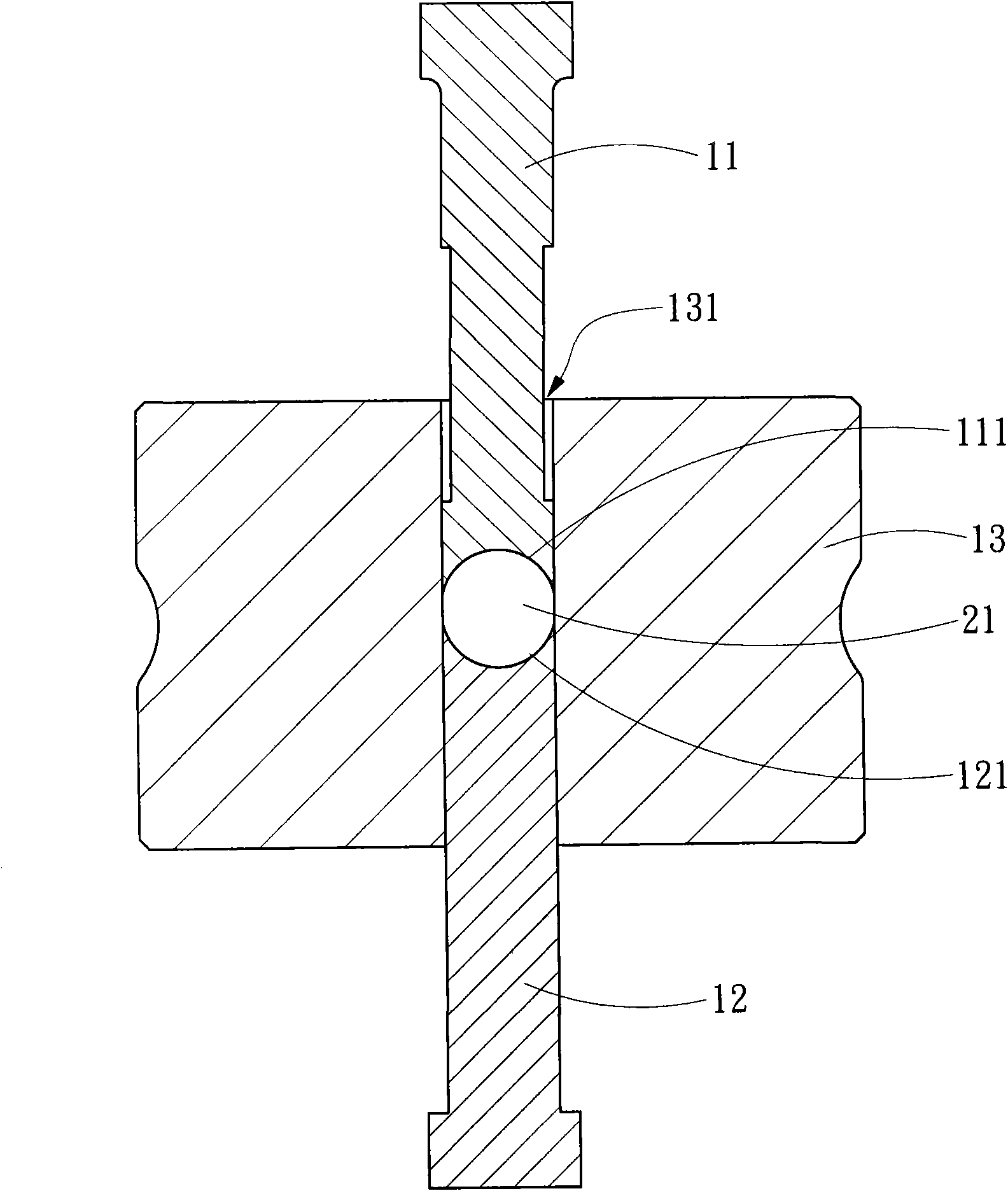

[0019] The detailed description and technical content of the present invention will now be described in conjunction with the accompanying drawings.

[0020] see figure 2 as shown, figure 2 It is a schematic cross-sectional view of a preferred embodiment of the present invention, as shown in the figure: the present invention is a BB shot forming device, including a top mold part 30 , a bottom mold part 40 and a middle mold part 50 . One end of the top mold part 30 is provided with a first forming groove 31 , and the first forming groove 31 has a first arc surface 311 and a first pushing member 312 inside the first arc surface 311 for pushing. The opposite end of the bottom mold part 40 to the first forming groove 31 is provided with a second forming groove 41, and a second arc surface 411 opposite to the first arc surface 311 is formed in the second forming groove 41, and a second arc surface 411 is provided on the second arc surface 411 There is a second pusher 412 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com