Green and environment-friendly printing process method

A green and environmentally friendly technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of poor absorption of polluted gases, large use limitations, wrong drying, etc., to enhance green environmental protection performance, enhance Environmentally friendly performance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

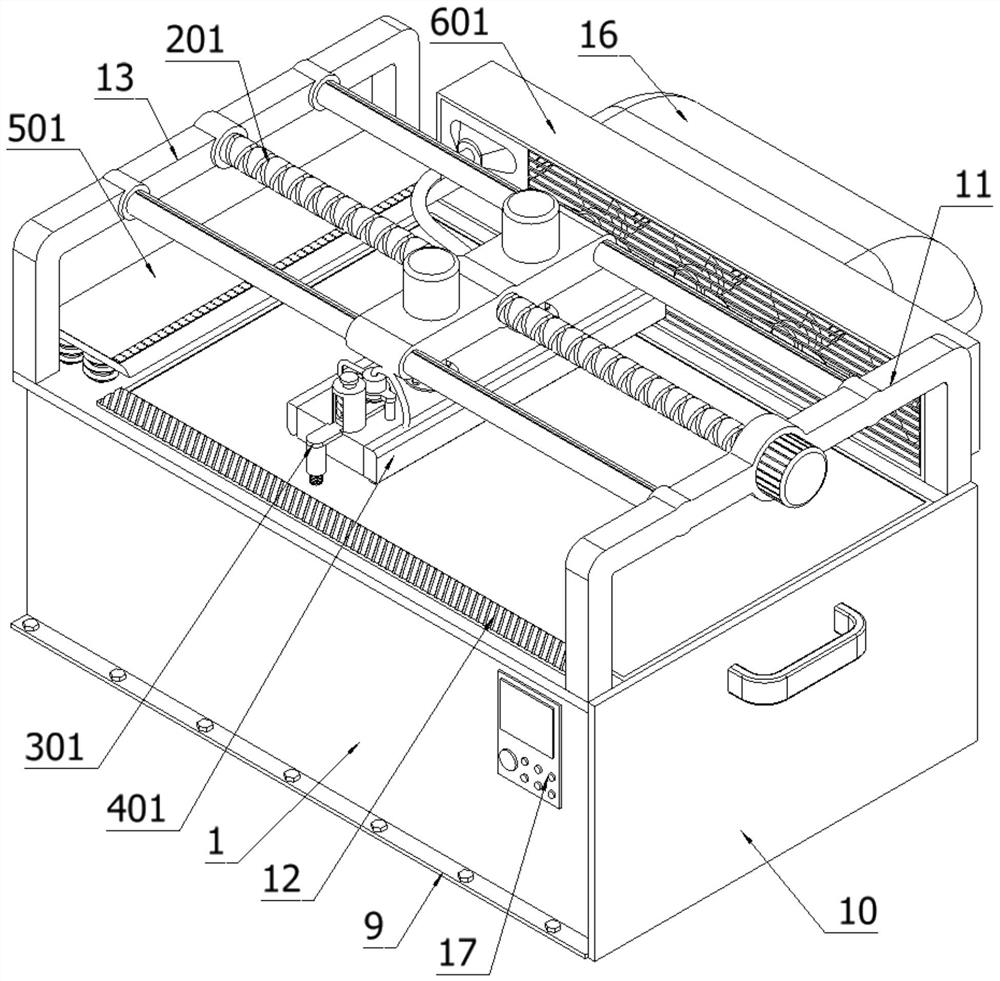

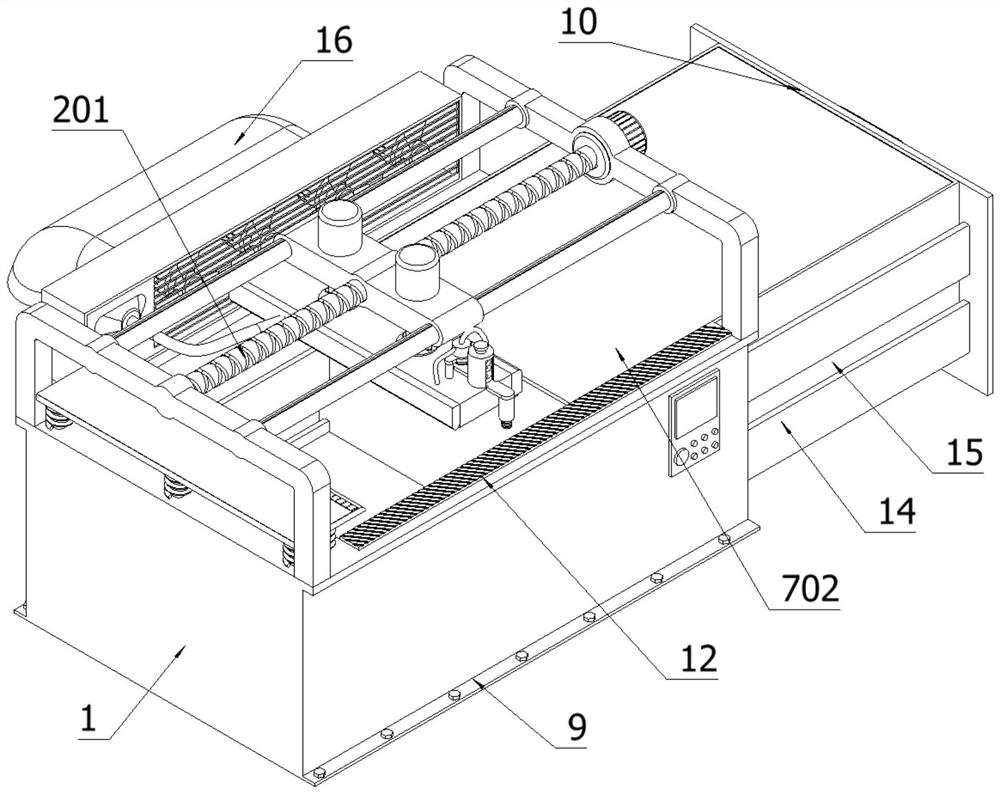

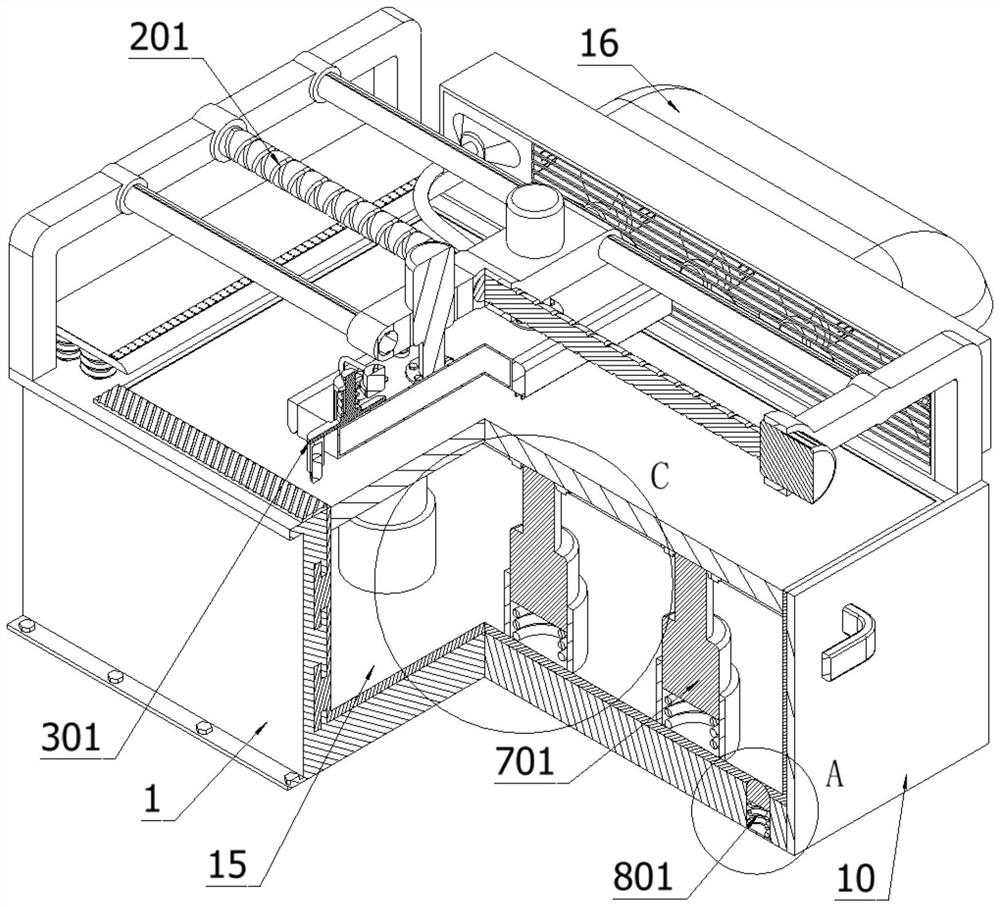

[0032] as attached figure 1 to attach Figure 11 Shown:

[0033] The invention provides a green environmental protection printing process method, the green environmental protection printing process method uses the green environmental protection printing process equipment to complete the printing process; the green environmental protection printing process equipment includes an installation shell 1; the two sides of the bottom of the installation shell 1 Both are fixedly connected with the shell mounting plate 9, and the bottom of the shell mounting plate 9 is flush with the bottom of the mounting shell 1; There is a driving device 2; the shaft end of the driving device 2 is fixedly set on the shaft end fixing bracket 13, and the bottom of the shaft end fixing bracket 13 is fixedly connected to the top of the rear side of the installation housing 1; the bottom of the driving device 2 is fixedly connected to the precision printing device 4, And the top of the precision printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com