Vertical pneumatic filling device and using method thereof

A filling device and vertical technology, applied in the field of vertical pneumatic filling devices, can solve the problems of high viscosity, difficult to flow, difficult to clean the equipment, and bubbles generated during processing, so as to reduce the dead angle of cleaning, easy to package the total amount, Ease of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

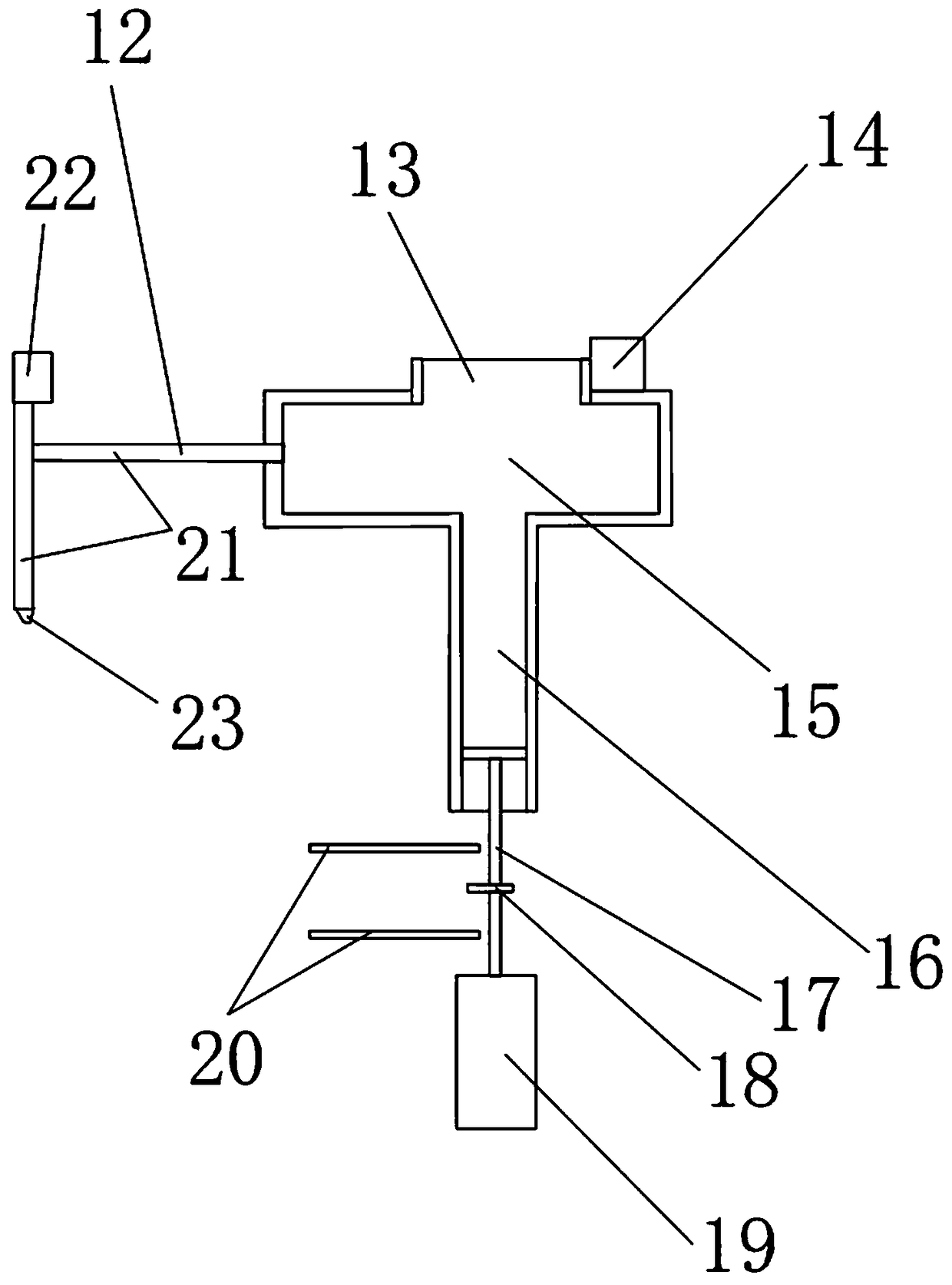

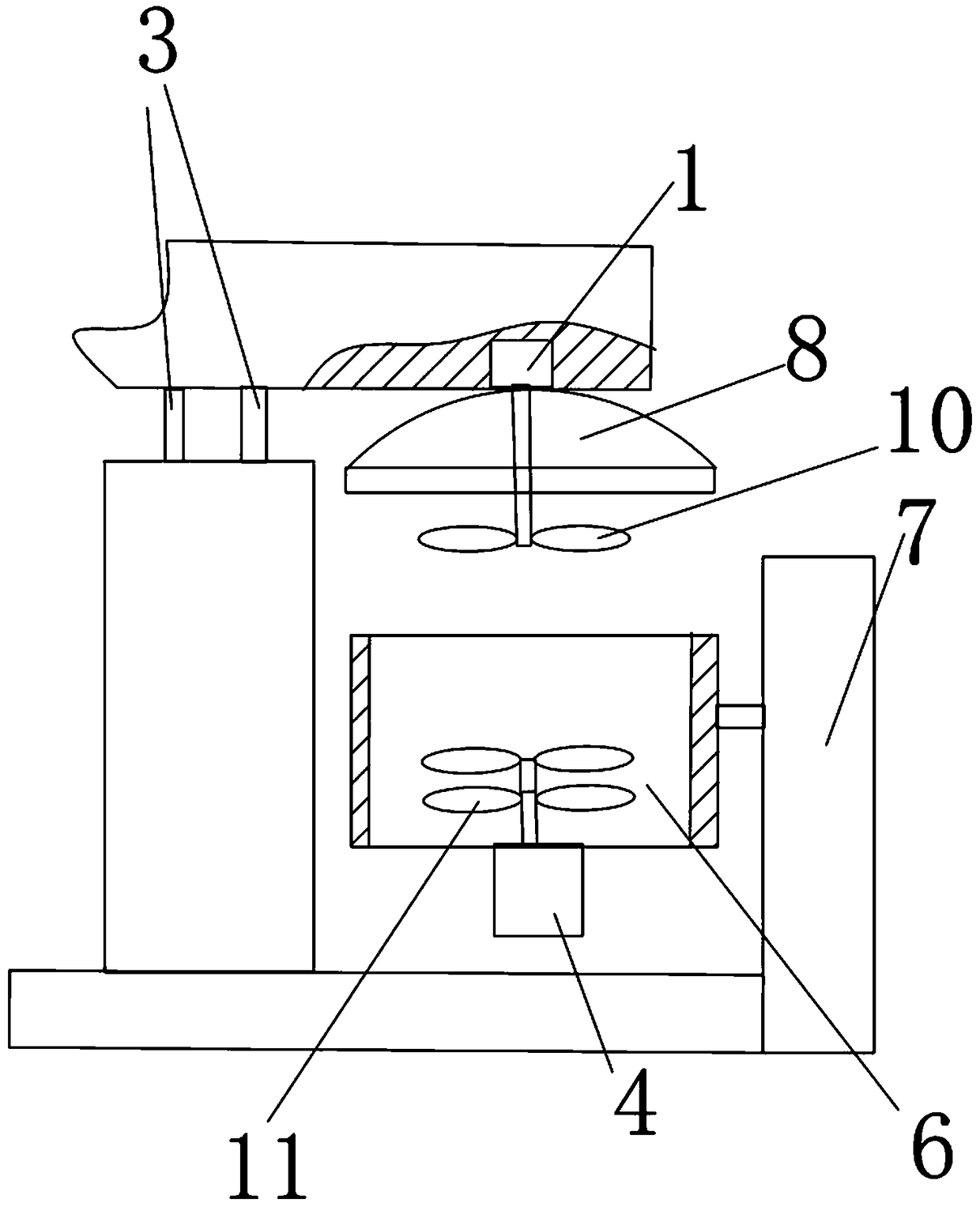

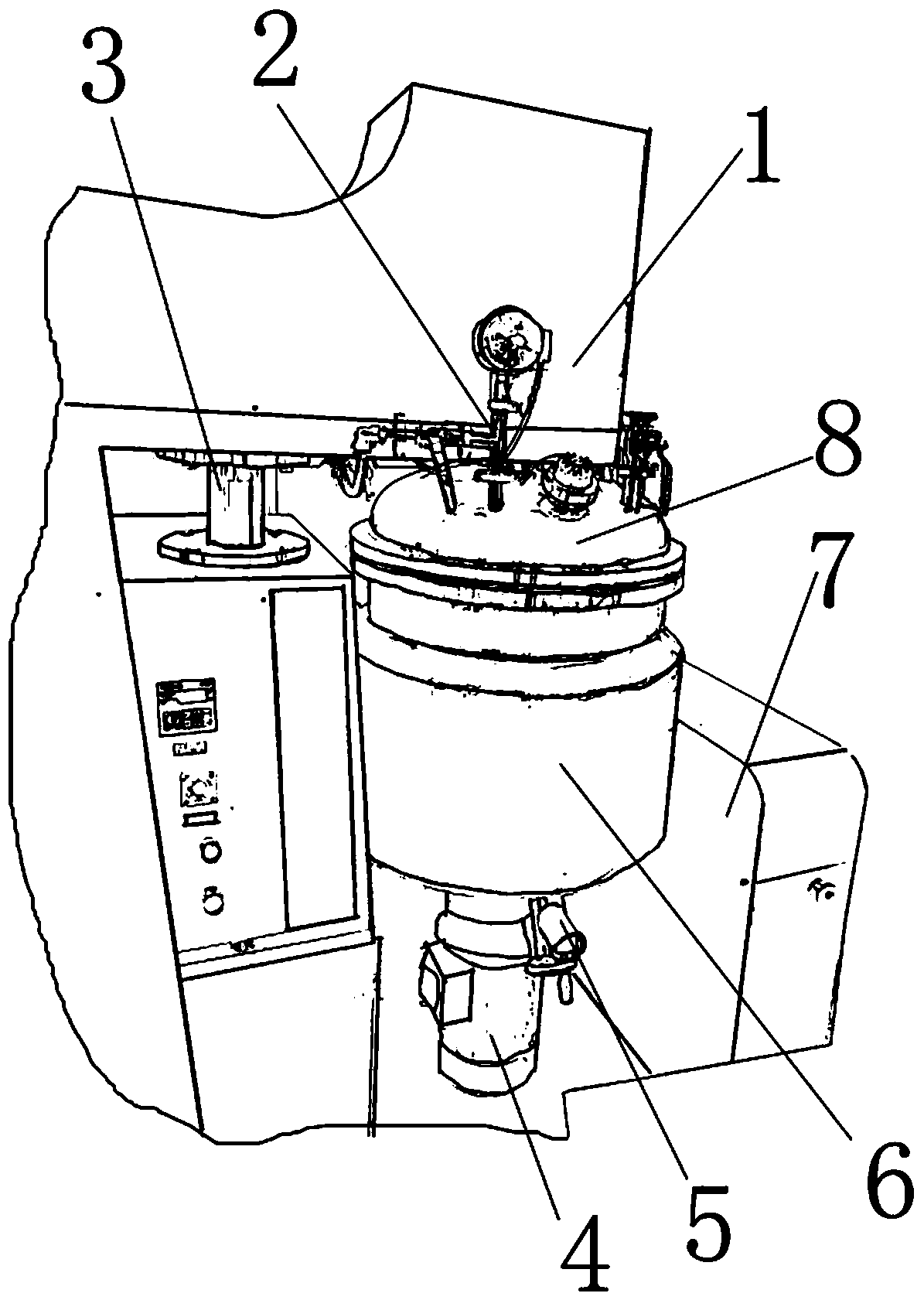

[0029] Such as Figure 1-3 As shown, a vertical pneumatic filling device, the filling mechanism of the filling device includes a control module, a temporary storage chamber 15, a suction mechanism and an extrusion mechanism, and the input port 13 of the filling mechanism is located in the temporary storage chamber 15 A check valve 14 is provided at the wall of the chamber; the suction mechanism is connected to the temporary storage chamber 15 with a suction cylinder 16; when the filling operation is performed, the check valve 14 leads to the input port 13 of the filling mechanism, and the suction mechanism Drive the suction cylinder 16 to suck the preset temporary storage amount of the material to be filled into the temporary storage chamber, then the check valve 14 closes the filling mechanism input port 13, and the suction mechanism reversely drives the suction cylinder 16 to the temporary storage chamber 15. The filling material exerts pressure, and the extruding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com