Patents

Literature

74results about How to "Reduce cleaning dead space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sterilizing and disinfecting device for medical operation instruments

PendingCN107982559AWon't touchAvoid secondary pollutionLavatory sanitoryChemicalsInstrument trayControl switch

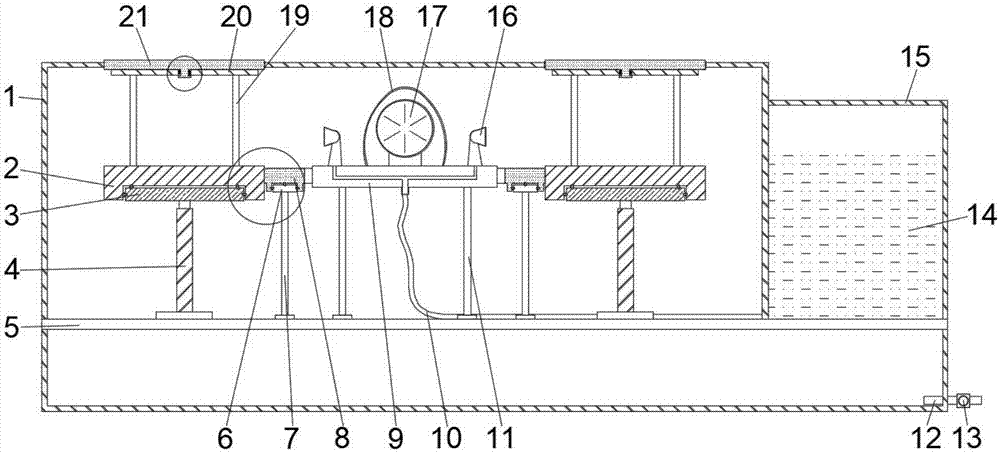

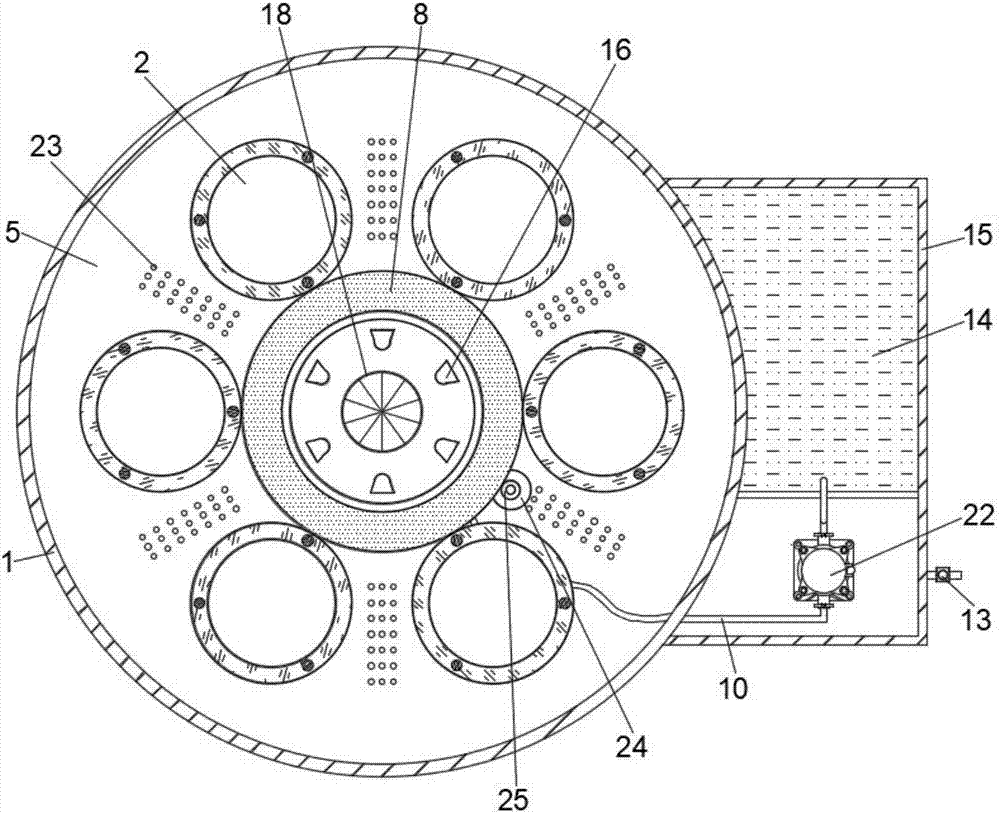

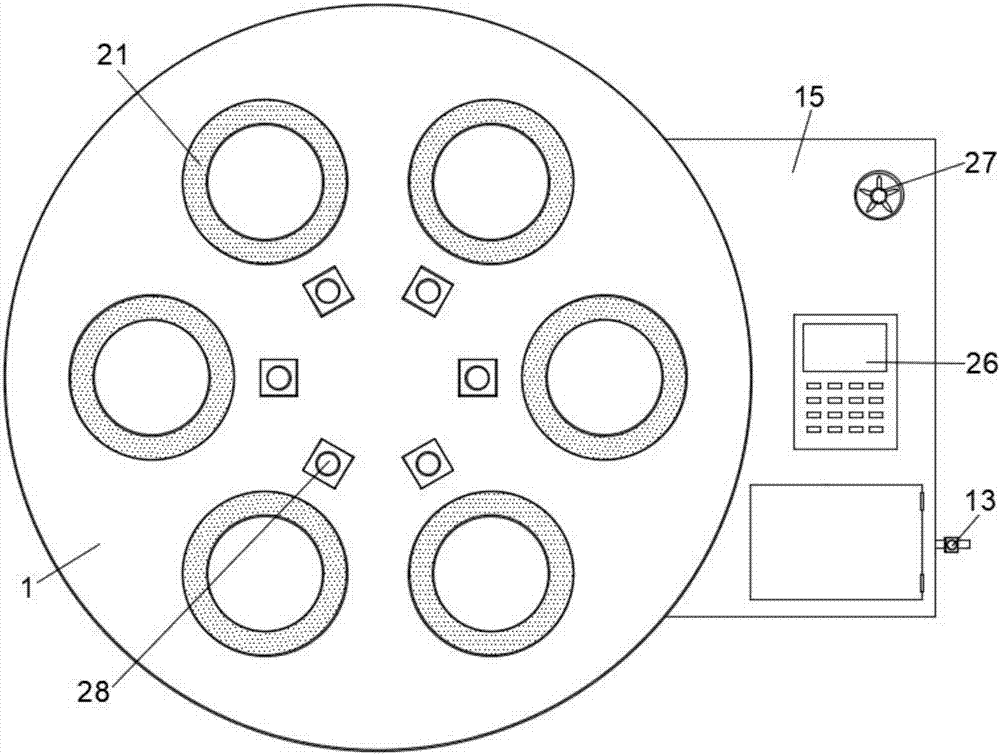

The invention provides a sterilizing and disinfecting device for medical operation instruments. The sterilizing and disinfecting device comprises a main box body, operation instrument trays and a bottom plate, wherein each operation instrument tray is movably arranged at the top part of a tray support plate; a control panel is fixedly arranged at the top part of a side box body; the top part of the side box body is fixedly provided with a disinfecting liquid filling port; six electrical push rod control switches are fixedly and symmetrically arranged at the top part of the main box body. The sterilizing and disinfecting device has the advantages that by arranging the operation instrument trays, the secondary pollution is favorably avoided, and the use efficiency is improved; when the operation instruments need to be placed and disinfected in the disinfecting process, the electrical push rod control switch corresponding to the idle operation instrument tray is directly pressed down, andthen the operation instrument is put at the top part and is recycled; in the placing process, the other operation instruments are not touched, so that the secondary pollution is avoided; the operation instruments can be singly fetched for use, and the other operation instruments are not in contact with the outside environment; more convenience in use is realized.

Owner:陈颖

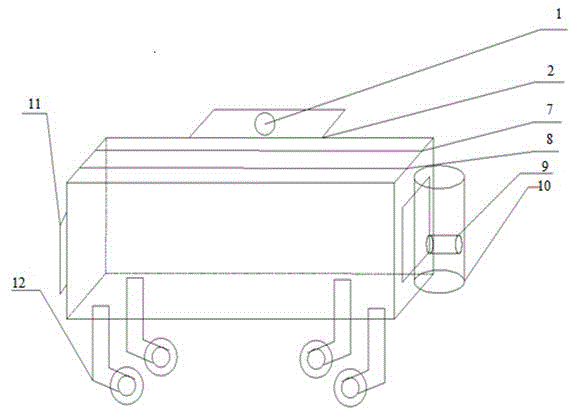

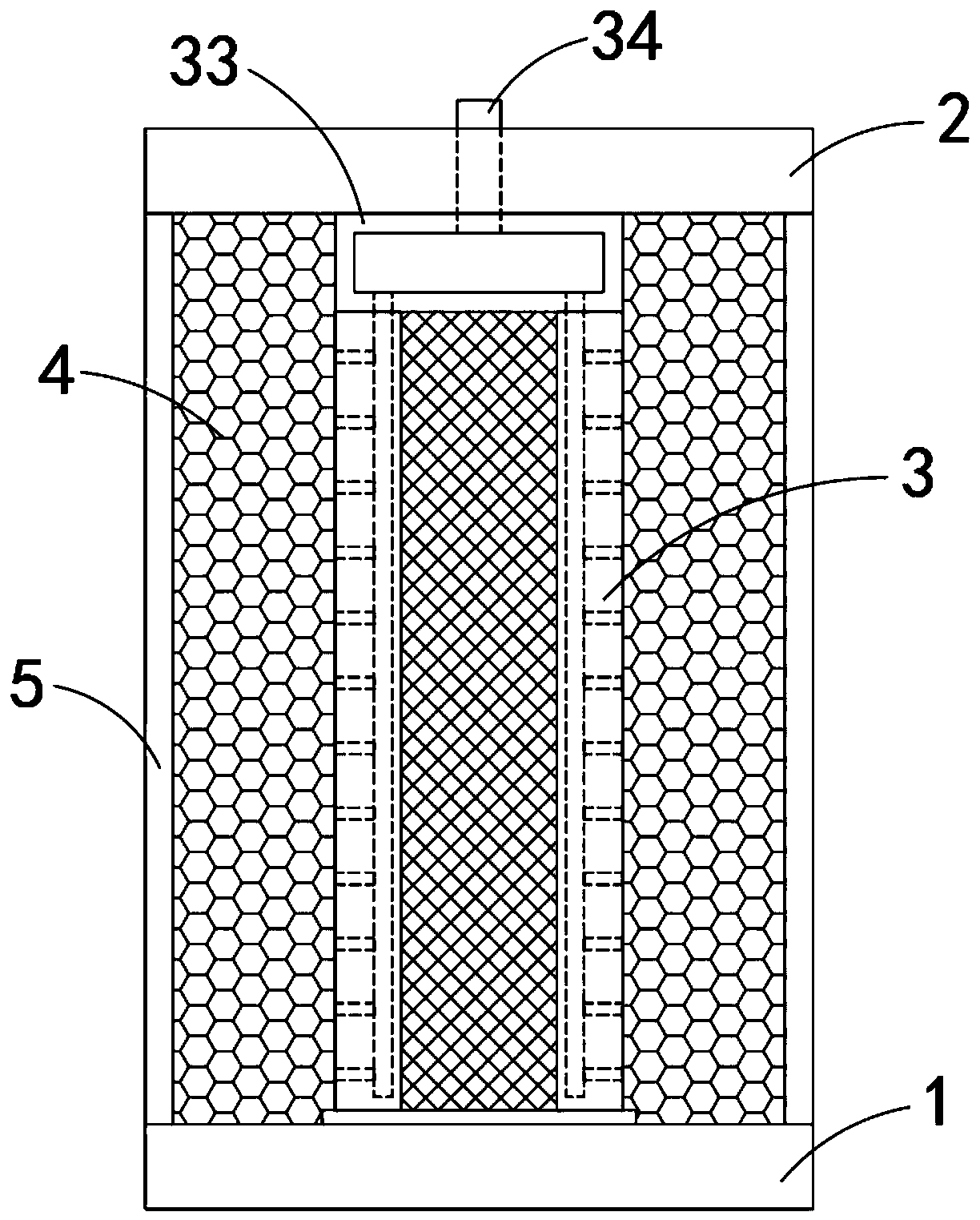

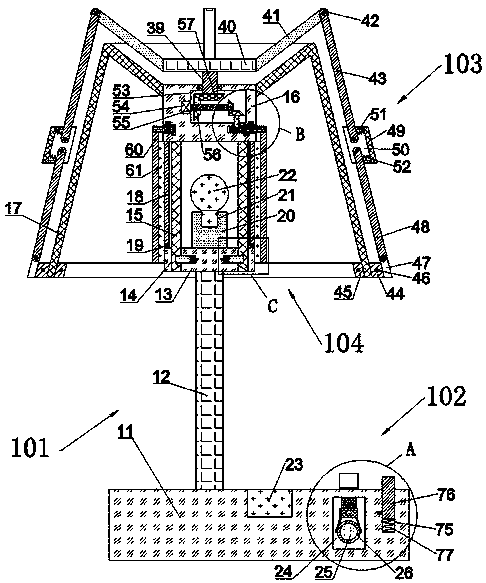

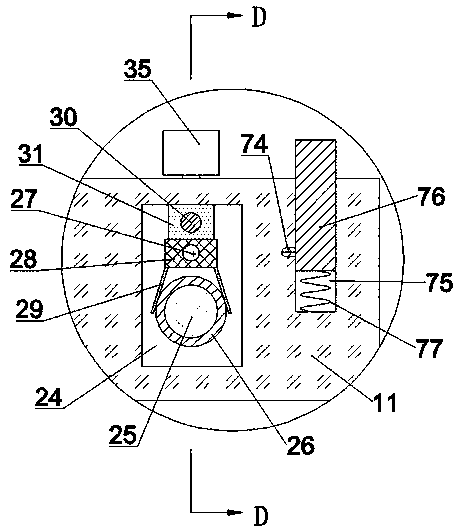

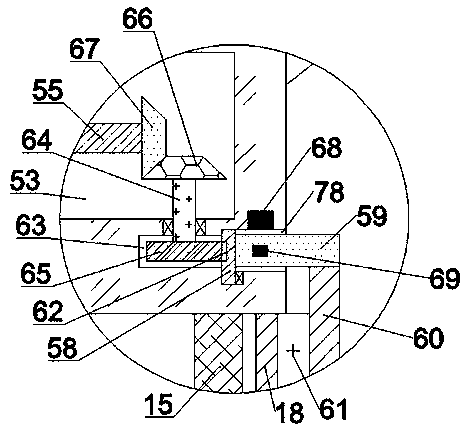

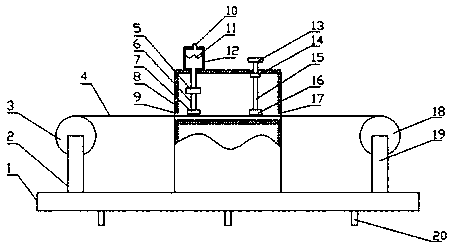

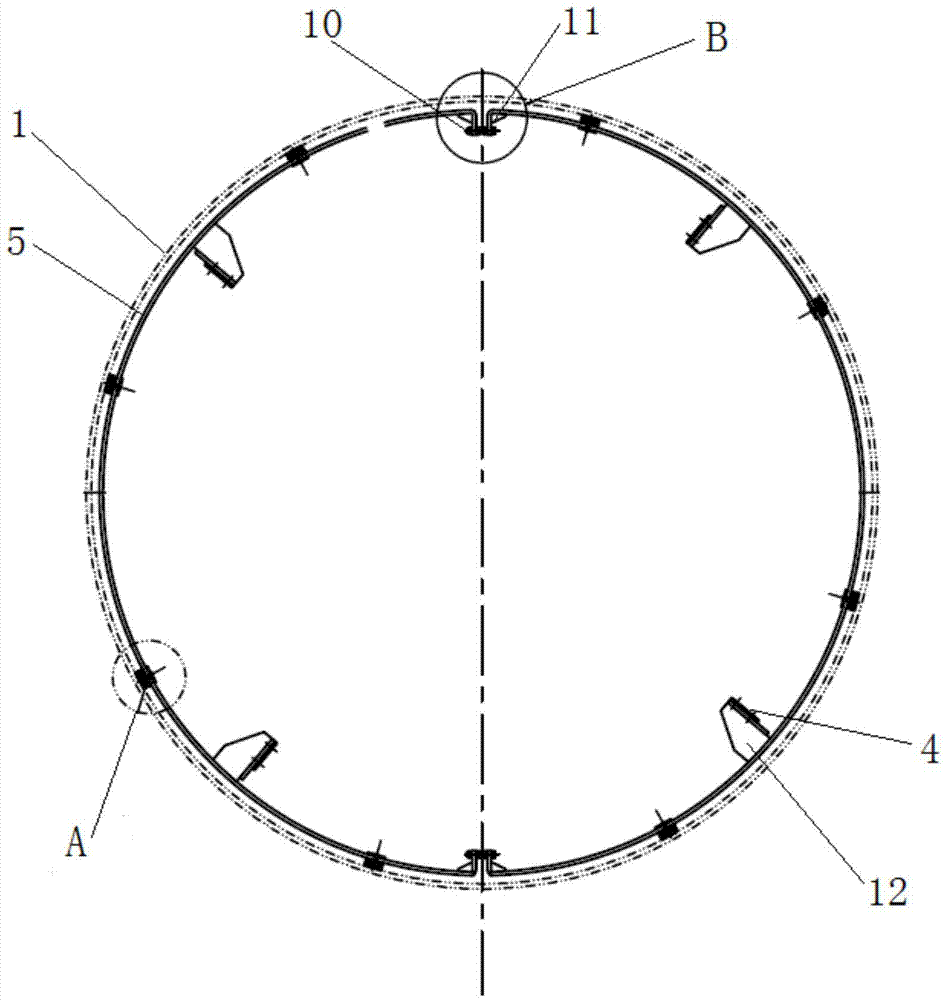

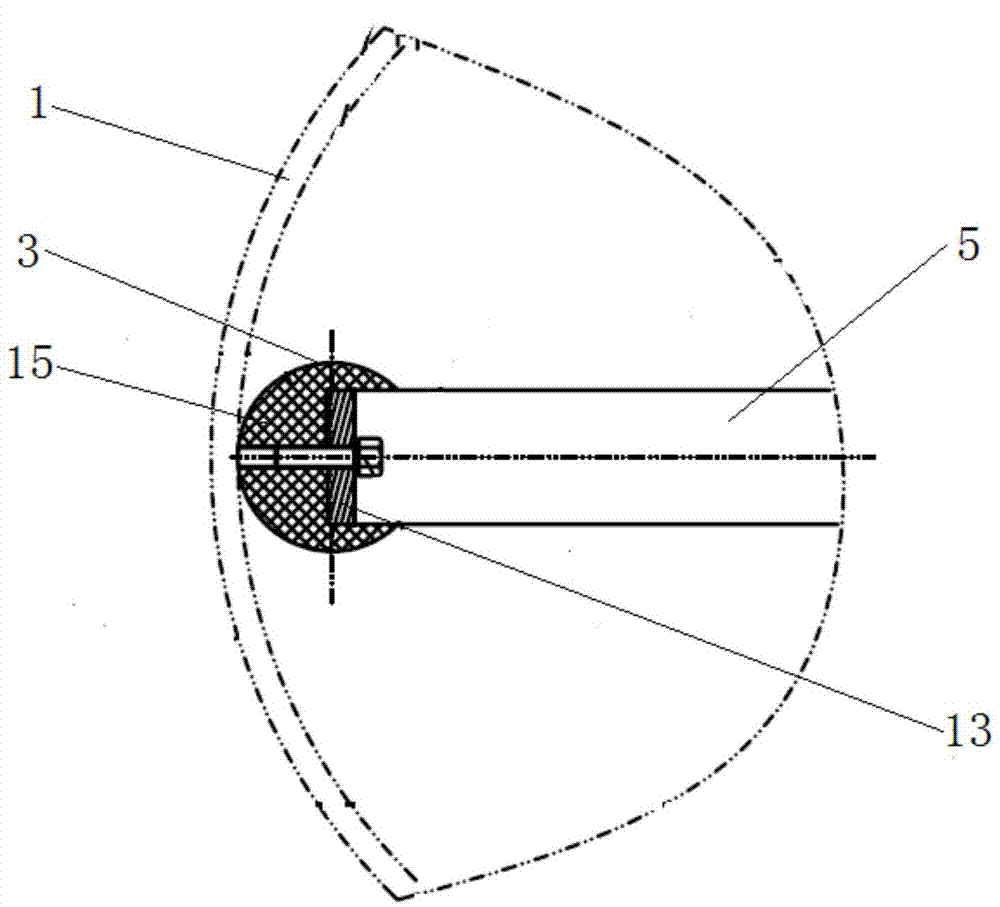

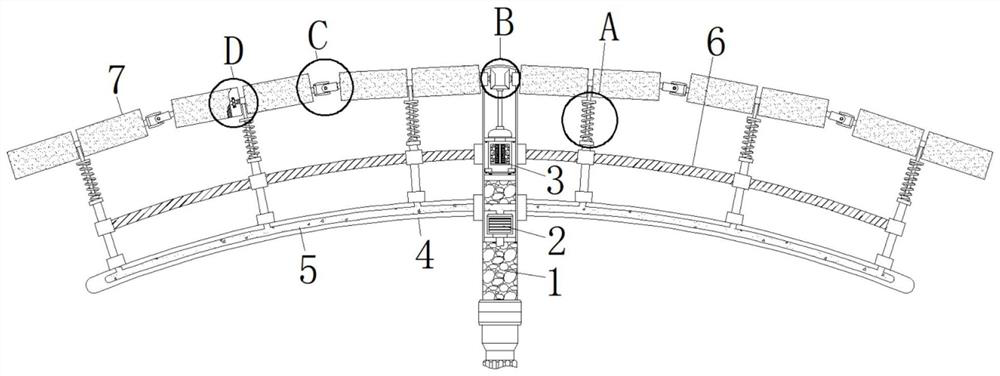

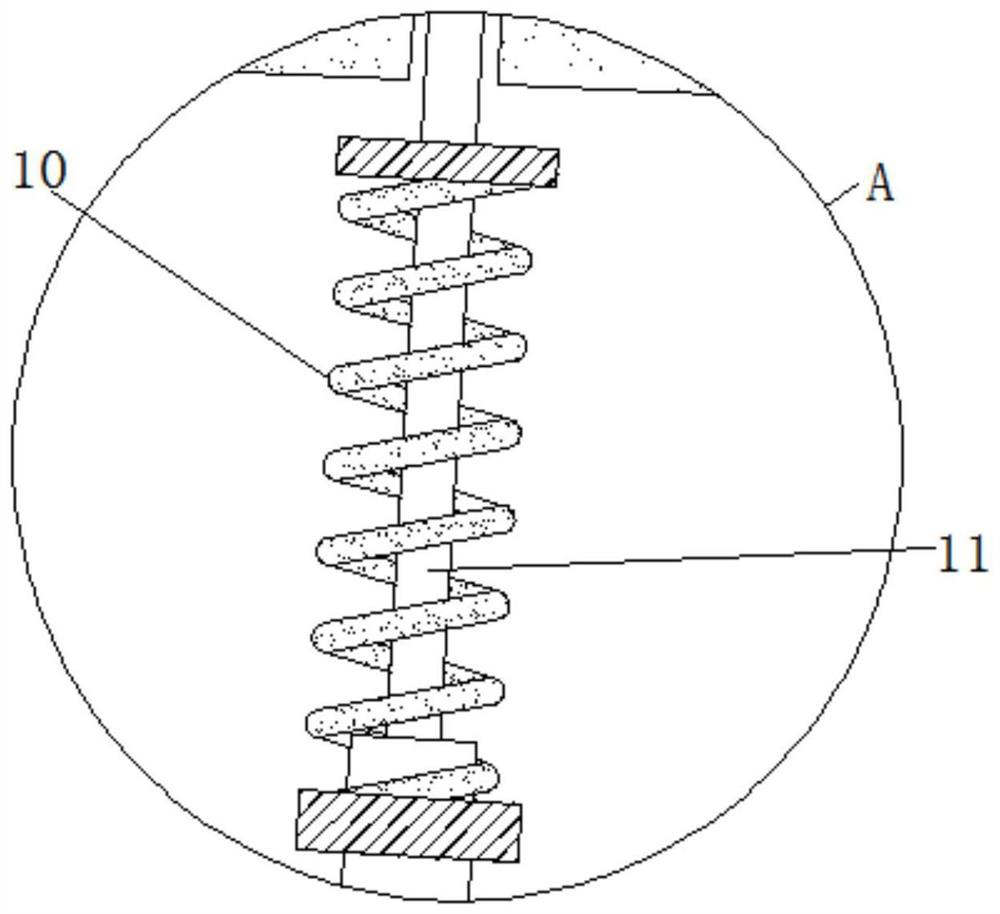

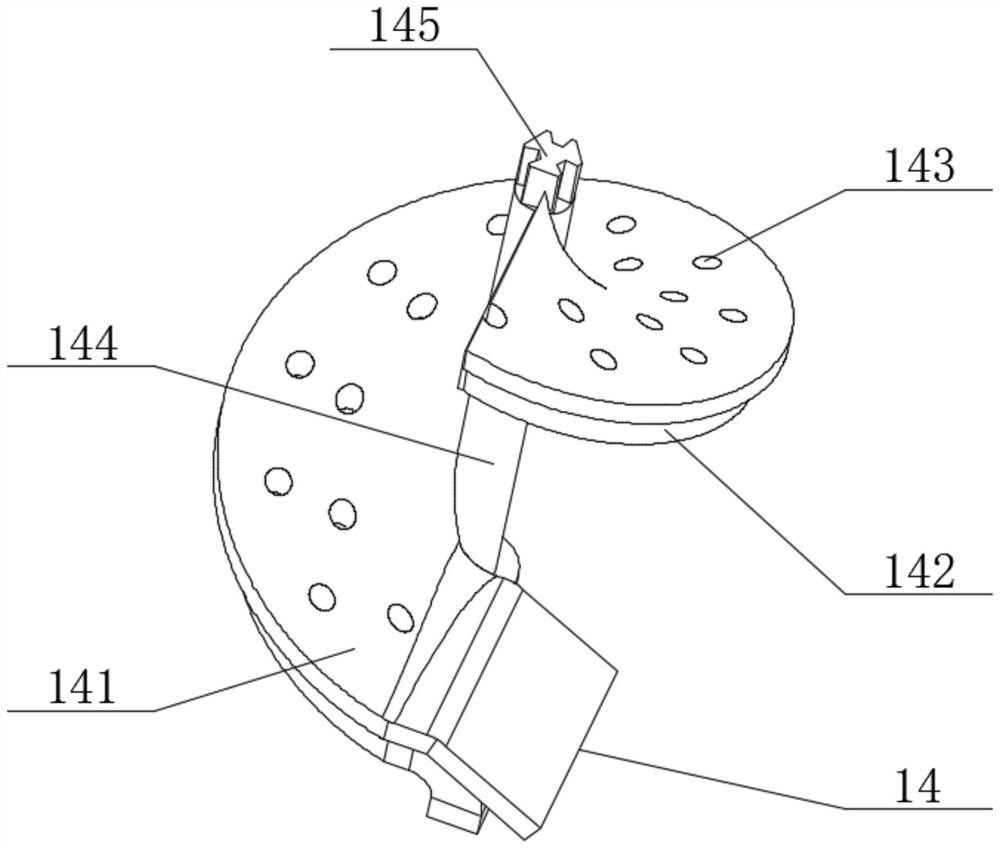

Efficient and intelligent solar cell panel cleaning device

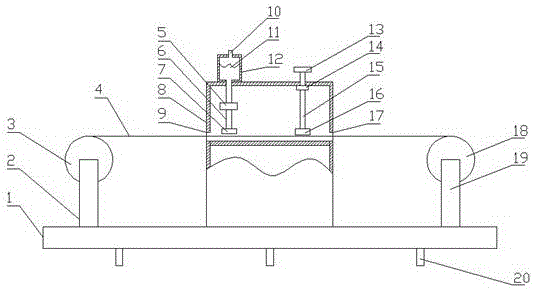

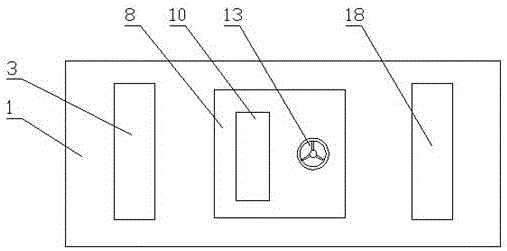

ActiveCN104550160AReduce cleaning dead spaceReduce the phenomenon of water flow awayPhotovoltaicsFlexible article cleaningPhysicsWater pipe

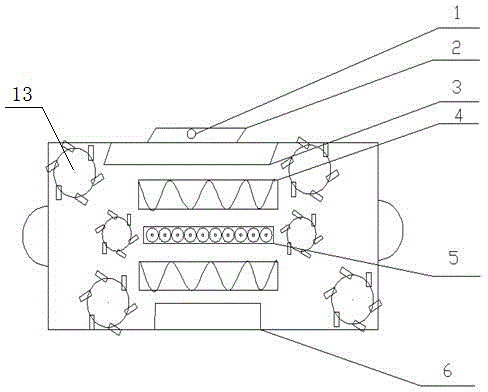

The invention relates to cleaning devices, particularly to an efficient and intelligent solar cell panel cleaning device. The efficient and intelligent solar cell panel cleaning device is characterized by comprising a device body; in the moving direction of the device body, the left end and the right end of the lower surface of the device body are provided with three six-stage hairbrush devices respectively which are distributed in an S shape; meanwhile, the middle of the lower surface of the device body is provided with an efficient atomizing spray device, and the upper side and the lower side of the efficient atomizing spray device are provided with roller type hairbrushes; the rear end of the lower surface of the device body is provided with an absorbing port, and correspondingly, the front end of the lower surface of the device body is provided with a traction plate; the front surface of the device body is fixedly provided with a glass sheet; the glass sheet is provided with a rain sensor; the upper surface of the device body is fixedly provided with a water pipe, one end of the water pipe is connected with a water tank device fixed onto one side surface of the device body, and the other end of the water pipe is connected with the efficient atomizing spray device. The efficient and intelligent solar cell panel cleaning device can clean solar cell panels scientifically and efficiently.

Owner:JIANGSU UNIV

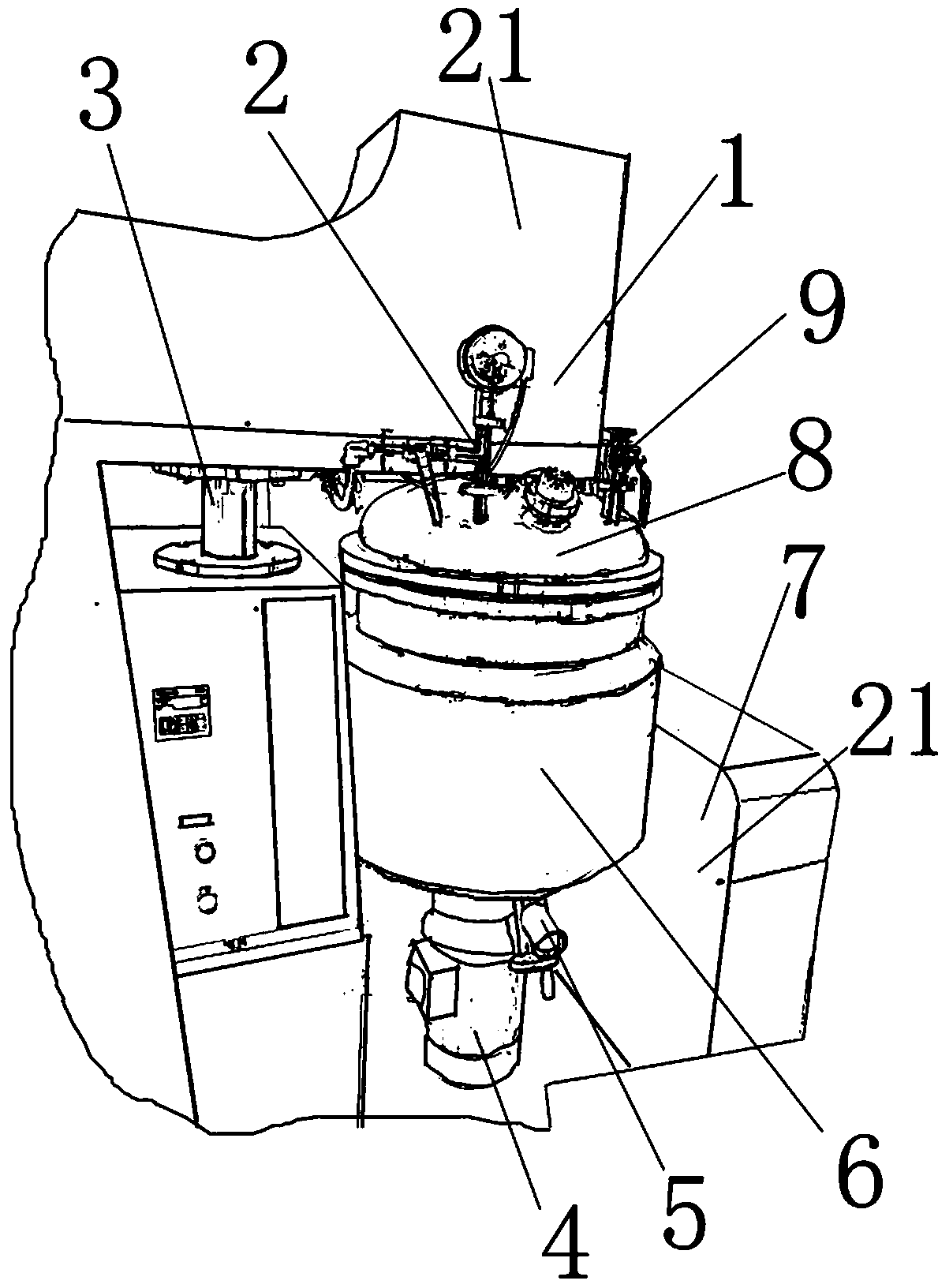

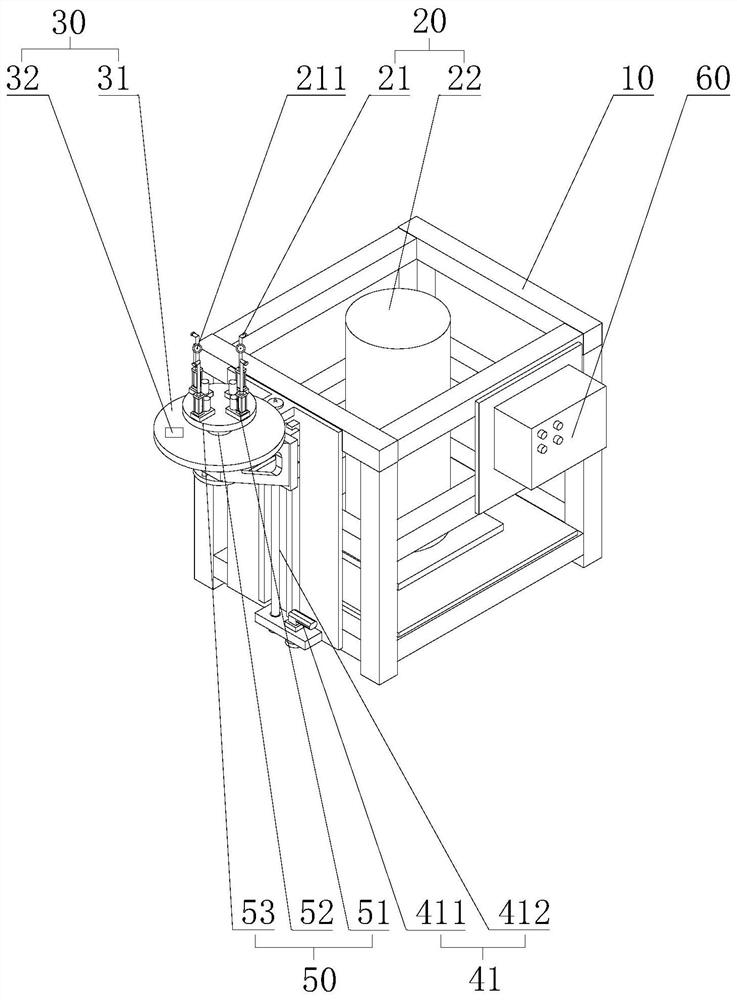

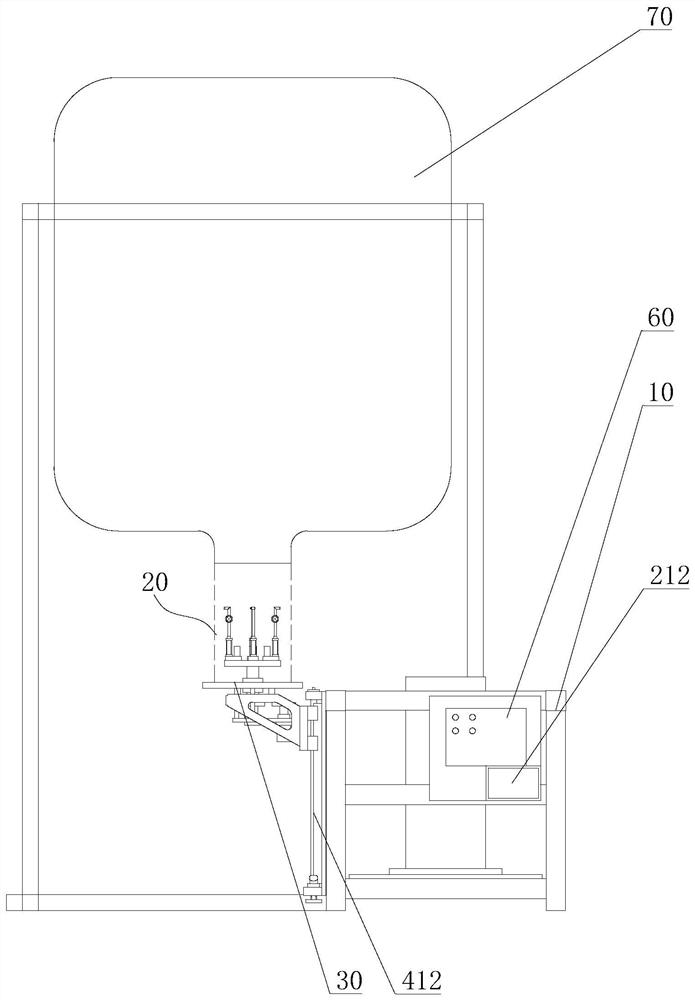

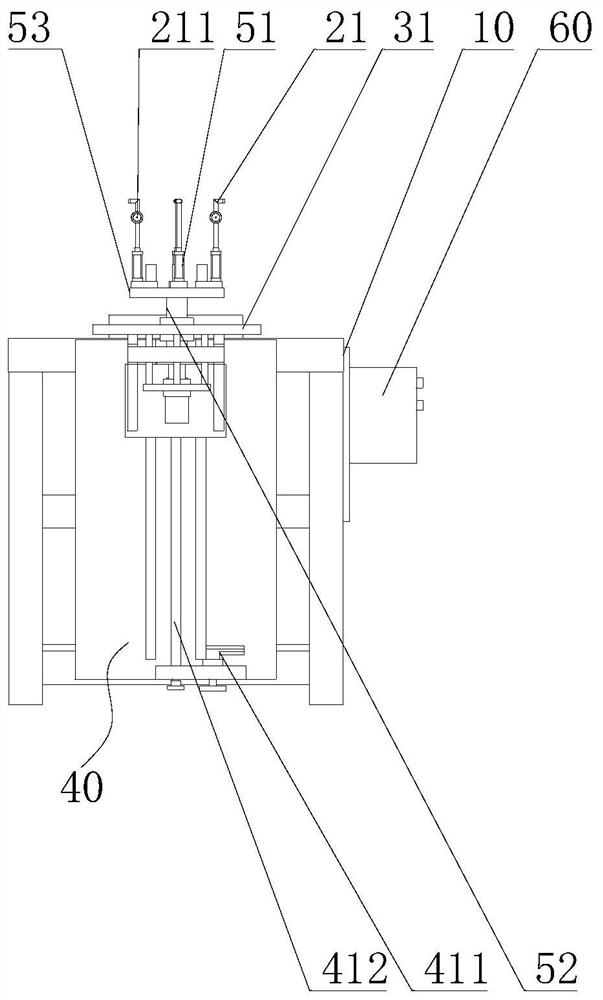

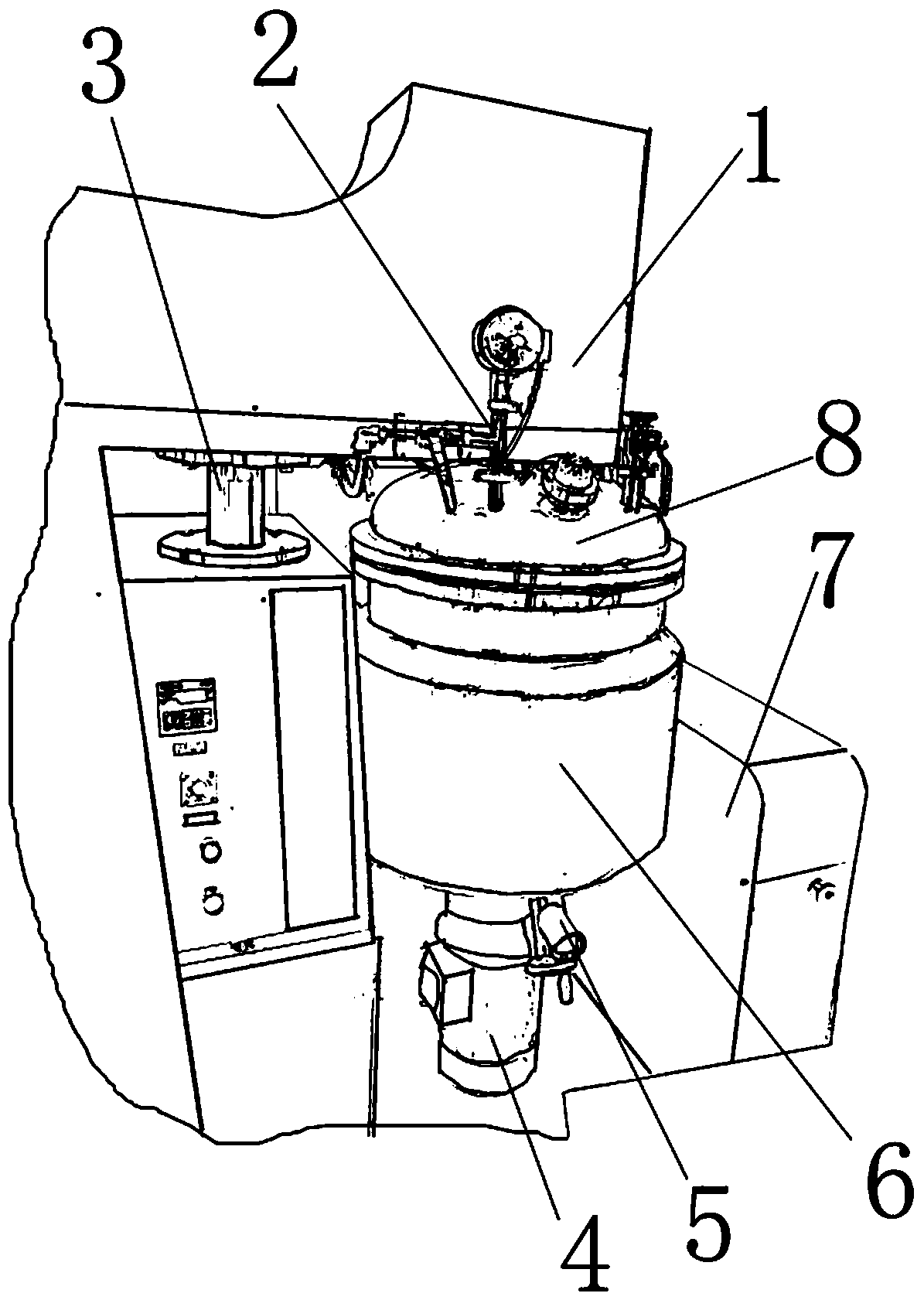

Homogeneous emulsification and filling integration device and application method thereof

PendingCN108295754ANot easy to affect the appearanceConvenient and quick escapeTransportation and packagingMixing methodsAir pumpPulp and paper industry

The invention provides a homogeneous emulsification and filling integration device and an application method thereof. The integration device comprises a homogeneous emulsification mechanism; the homogeneous emulsification mechanism comprises a control module, a vacuum tank and a machine table, a sucking pump and a first motor are connected to an upper cover of the vacuum tank, and the tank bottomof the vacuum tank is provided with a material outlet and a second motor which is connected with the vacuum tank into a whole; the first motor and the second motor are respectively connected with a stirring mechanism in the vacuum tank; the machine table is connected with the upper cover of the vacuum tank through a lifting mechanism, and is connected with a side wall of the vacuum tank through atank tilting mechanism; when the sucking pump is used for sucking air to form negative pressure, a material enters the tank through a pump-out slot of the vacuum tank; when a tank opening of the vacuum tank needs to be opened to operate, the machine table lifting mechanism is used for lifting the upper cover of the vacuum tank on the whole, and after the upper cover is separated from the tank bodyof the vacuum tank, the tank tilting mechanism is used for tilting the vacuum tank to an angle required. The homogeneous emulsification filling integration device can be conveniently used for carrying out homogeneous emulsification on a high-viscosity material, bubbles are difficult to generate in the processing process, and the device can further be cleaned and maintained conveniently.

Owner:福州法莫优科机械科技有限公司

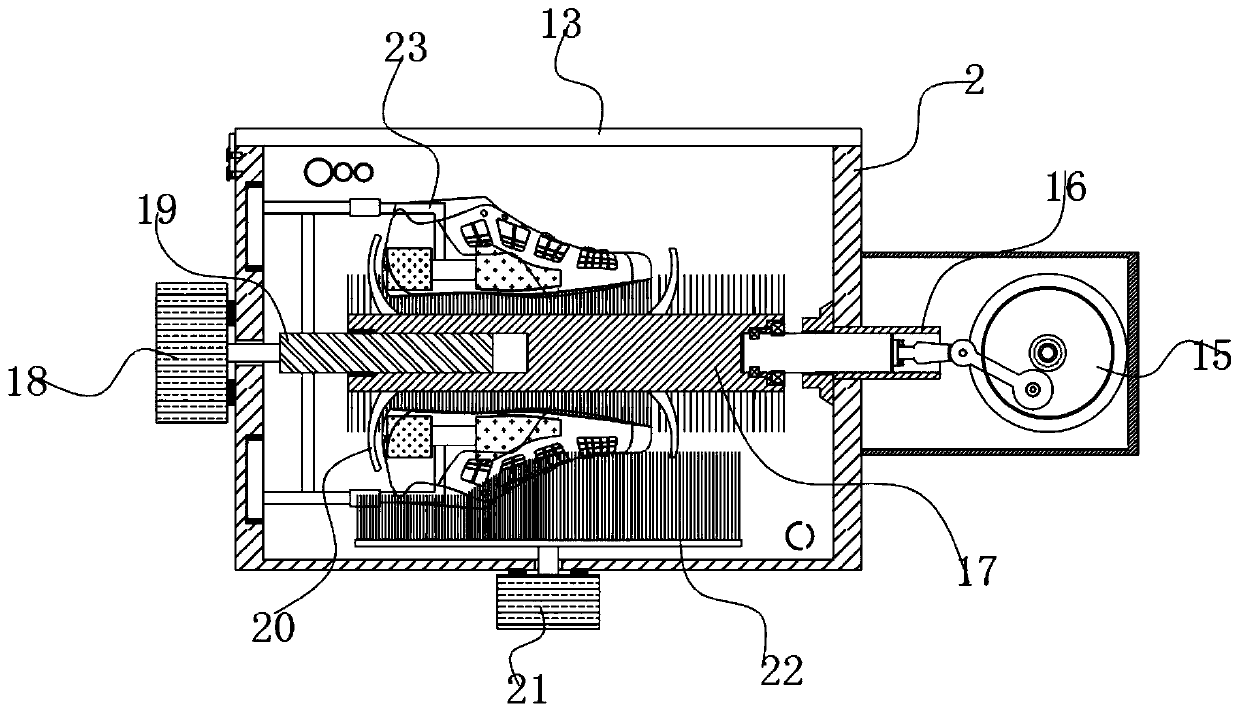

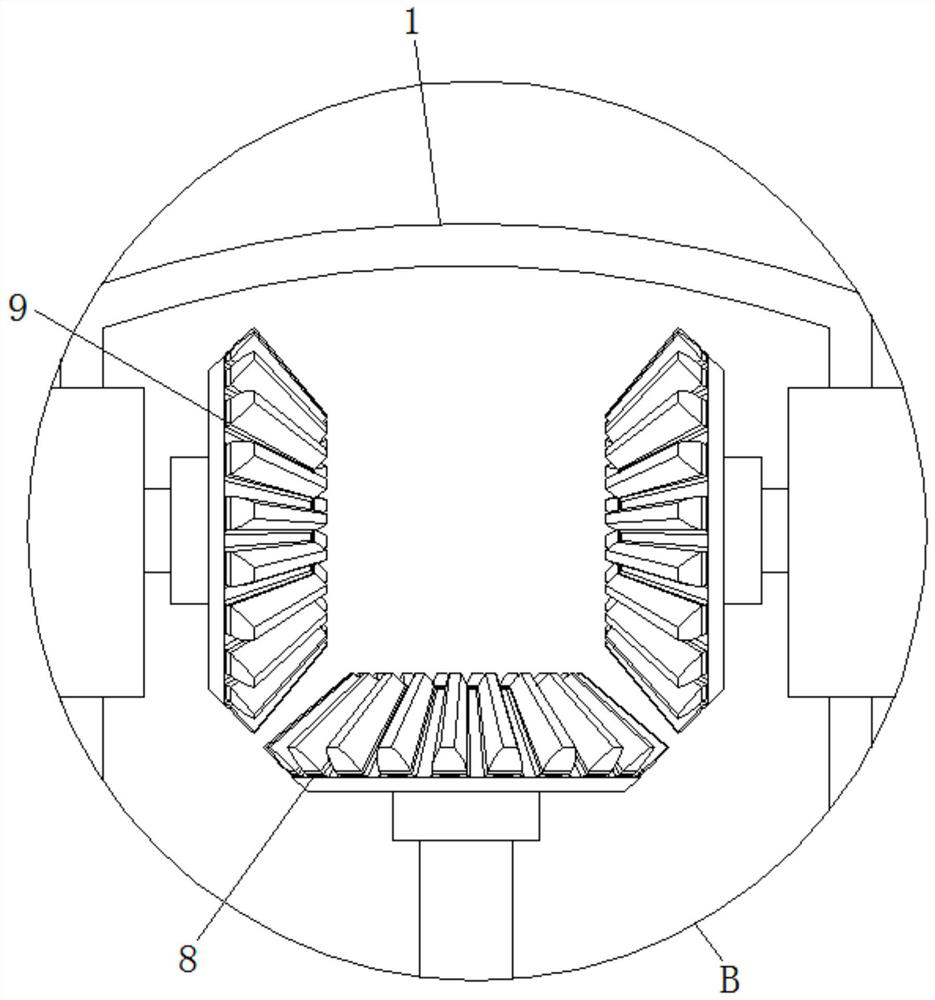

Disinfection cabinet used for surgical forceps and scissors

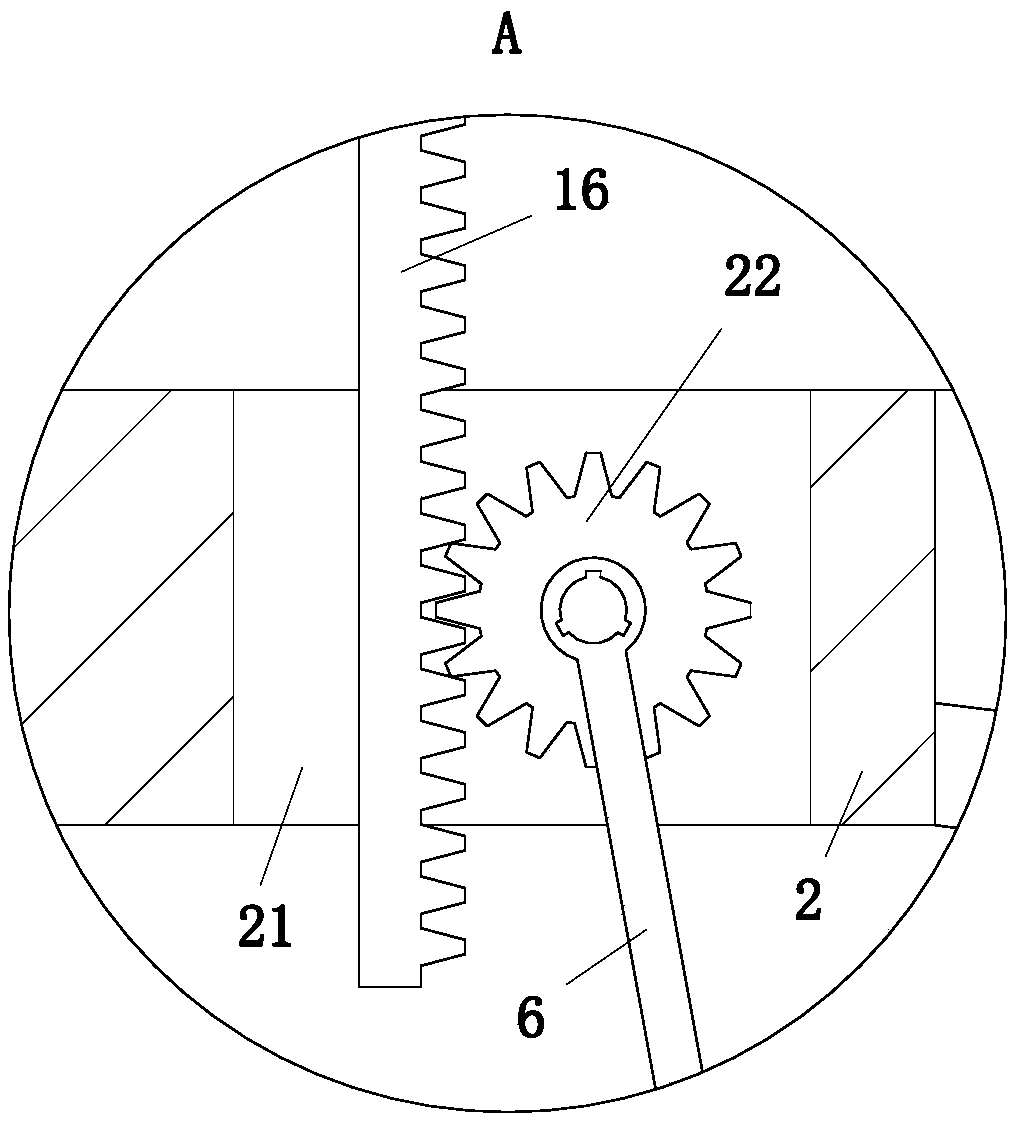

ActiveCN111166920AReduce cleaning dead spaceSpeed up disinfectionDrying solid materials with heatDiagnosticsForcepsEngineering

The invention discloses a disinfection cabinet used for surgical forceps and scissors. The disinfection cabinet comprises a cabinet body; a moving channel is arranged in the cabinet body; a moving device is arranged in the cabinet body; the moving device includes a first slider cavity arranged on the right wall of the moving channel in a communicating manner; a first slider which can slide forwardand backward is arranged in the first slider cavity; the left end face of the first slider is provided with a second slider cavity with an opening facing leftward; a second slider which can slide vertically is arranged in the second slider cavity; the left end of the second slider extends into the moving channel and is fixedly provided with a fixed block; the fixed block is provided with a clamping device; and a cleaning and disinfection device is arranged in the cabinet body. The disinfection cabinet can automatically clean and disinfect the surgical forceps and scissors quickly; compared with manual cleaning and disinfection, the disinfection cabinet reduces cleaning dead corners present due to mistakes in manual disinfection, and thus, thorough cleaning is realized; and meanwhile, thedisinfection speed and efficiency are improved, and labor intensity is significantly reduced.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

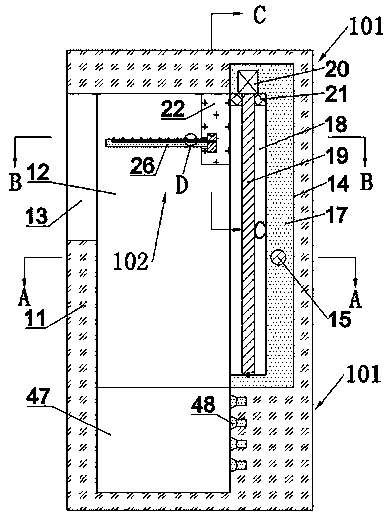

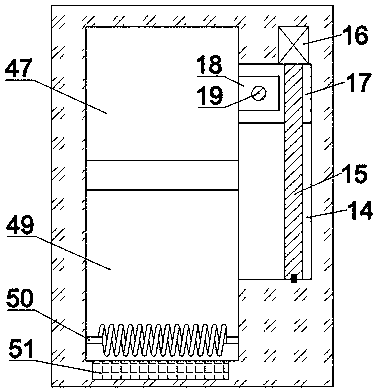

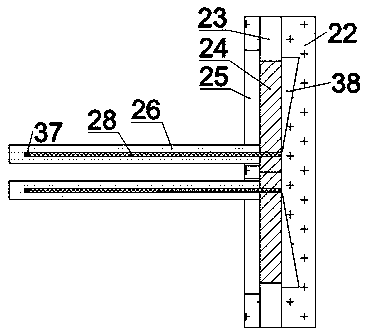

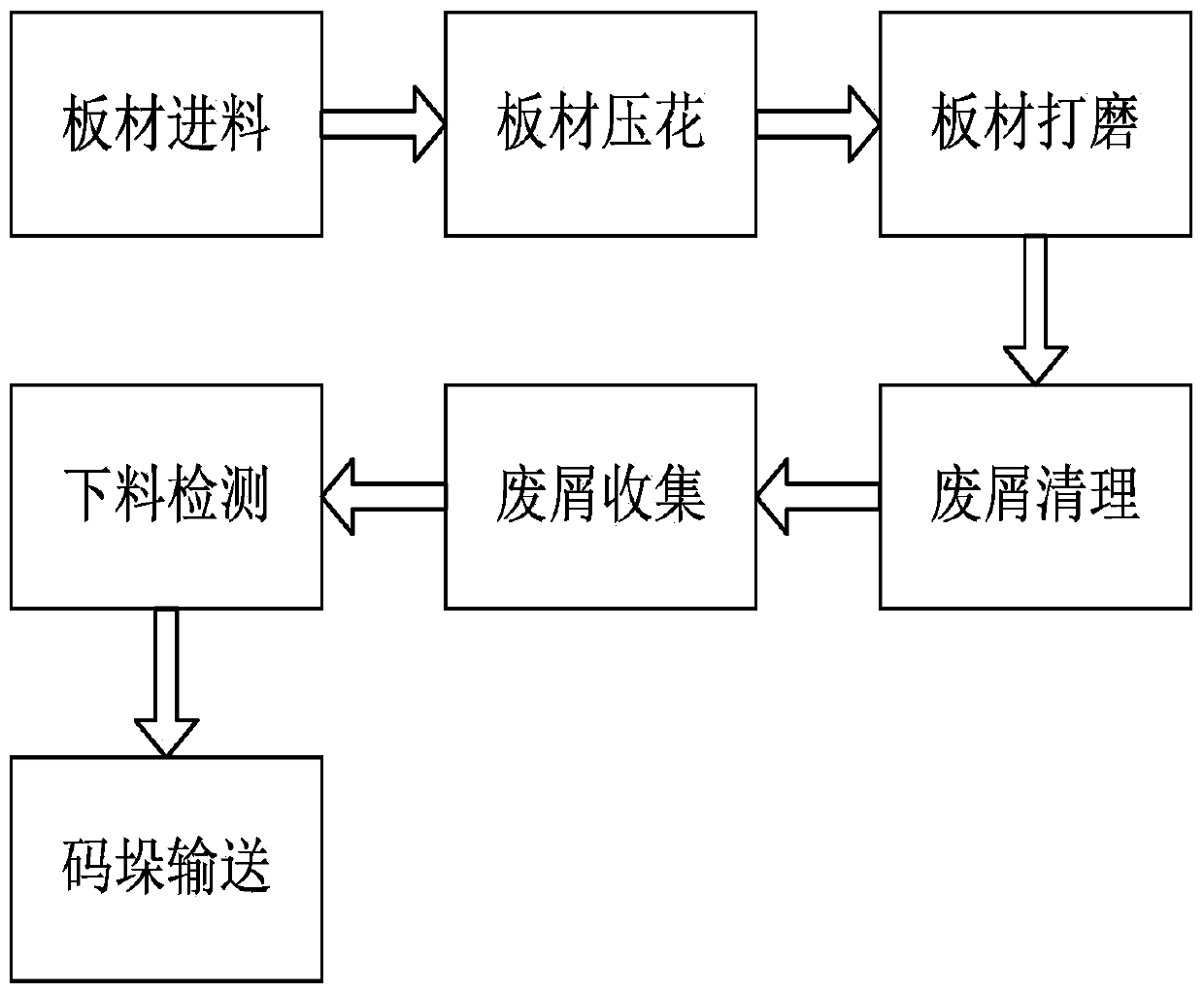

Stainless steel pattern plate embossing processing technology

ActiveCN110549775AUnified specificationsAvoid influencePlane surface grinding machinesEmbossing decorationsPulp and paper industryMetal

The invention relates to a stainless steel pattern plate embossing processing technology. A base, a feeding mechanism, an embossing device, a chip removing device and a driving device are included, wherein the feeding mechanism, the embossing device and the chip removing device are sequentially arranged at the front end of the base from bottom to top, a drive cavity and a collecting cavity are sequentially formed in the base from bottom to top, and a drive device is installed inside the drive cavity. According to the stainless steel pattern plate manufacturing processing technology, the left end and the right end of a rolled plate are polished, so that the formed stainless steel pattern plate is consistent in specification, bulges and burrs generated due to metal ductility are removed, waste chips generated after polishing are cleaned and collected, the influence of the waste chips on polishing is prevented, and the waste chips are collected, so that the influence of the waste chips ona machine and a production environment is prevented.

Owner:安徽银立方金属科技有限公司

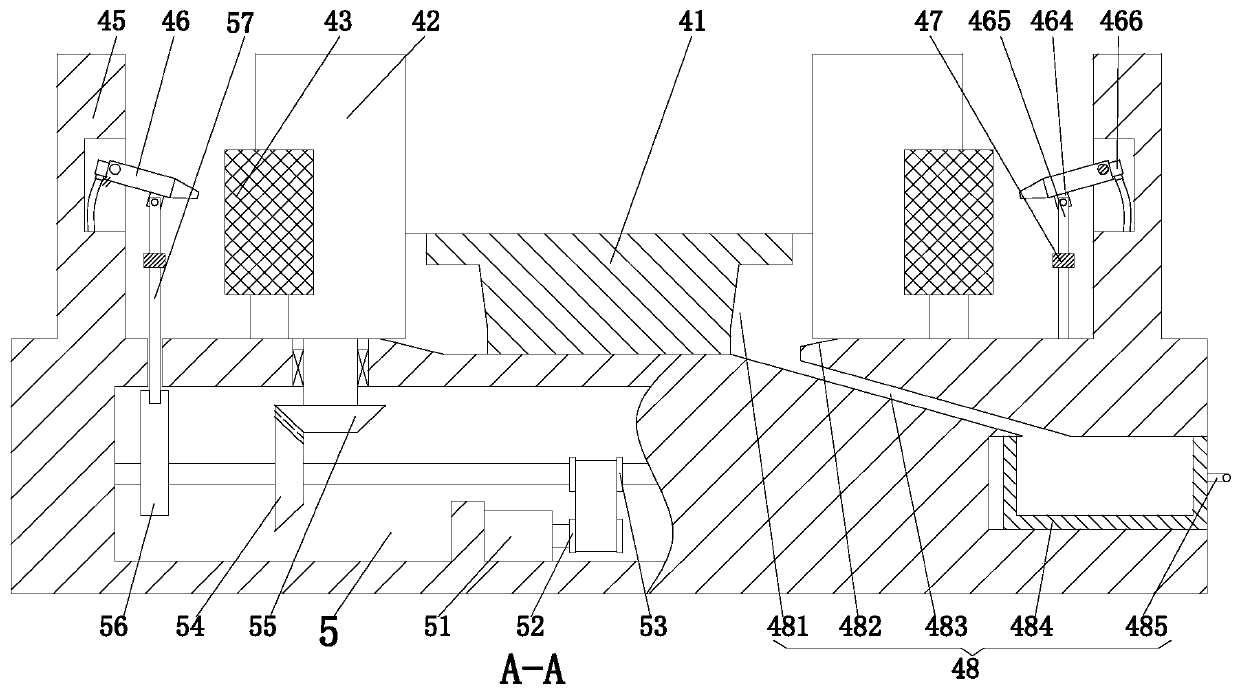

Self-rotating detachable easy-to-clean filter element

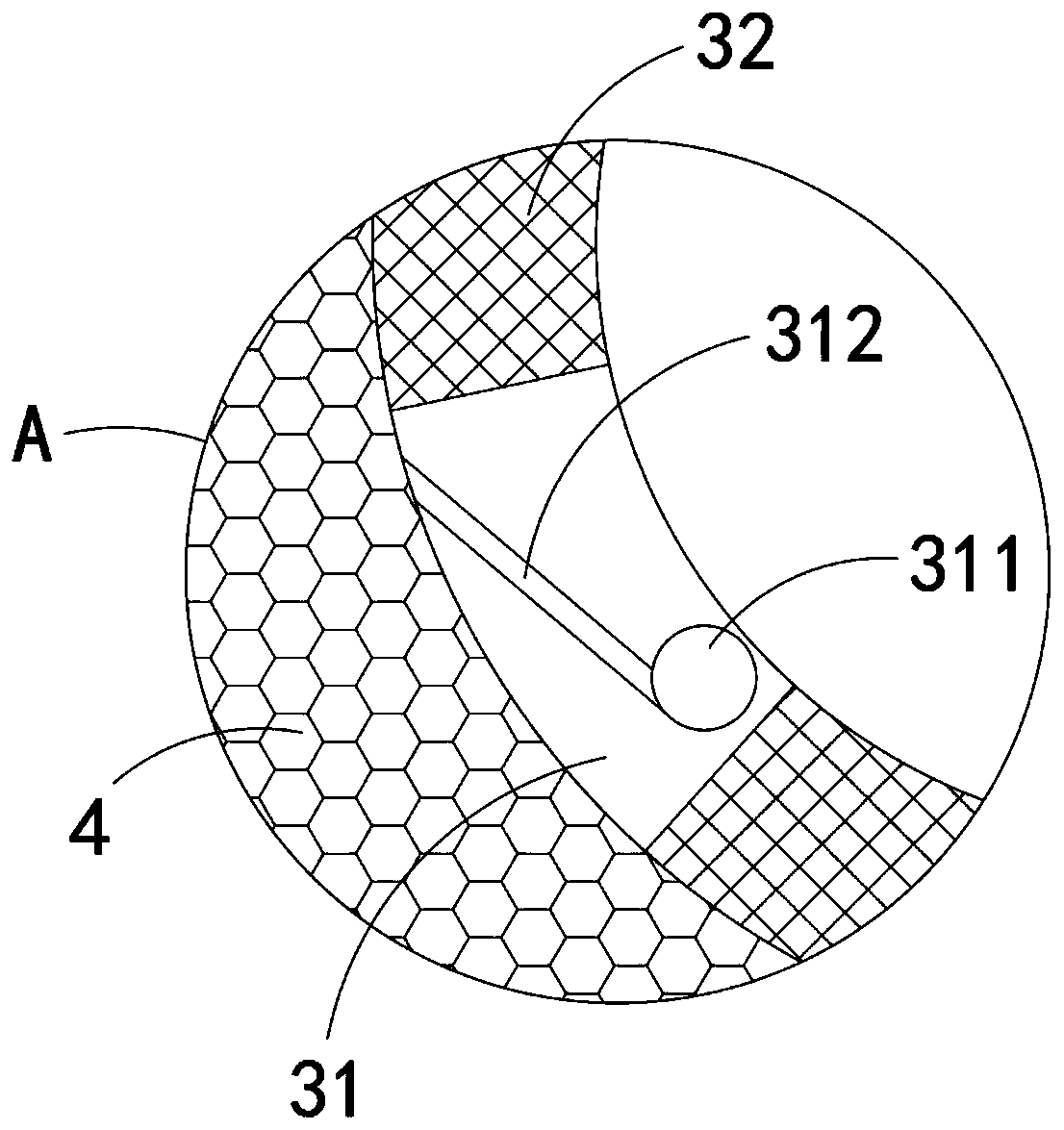

InactiveCN110523153AEasy to cleanReduce cleaning dead spaceDispersed particle filtrationTransportation and packagingEngineeringAir purification

The invention belongs to the technical field of air purification, and particularly relates to a self-rotating detachable easy-to-clean filter element. The filter element includes a base seat, a top seat, an inner cylinder, a filter element body and an outer cylinder; the inner cylinder can rotate freely along the axial direction, and the inner cylinder includes a plurality of fixing bars and filter net plates fixed among the fixing bars; the upper end of the inner cylinder is fixedly connected with a rotating cylinder, and the upper end of the rotating cylinder is fixedly connected with a gasinlet pipe that penetrates the top seat and is rotatably connected with the top seat; and one vertically-arranged gas outlet channel communicating with the rotating cylinder is arranged in each fixing bar, a plurality of horizontally-arranged gas discharging micropores are arranged in the side wall of each gas outlet channel, and the axes of the gas discharging micropores are rotationally symmetrically distributed with the axis of the inner cylinder. According to the filter element provided by the invention, the gas outlet channels and the gas discharging micropores are arranged, when high-speed flowing gas blows dust from the inside to outside, the counter-acting force generated by the gas discharging micropores drives the inner cylinder to rotate, so that the interior of the filter element body can be comprehensively cleaned, and the cleaning effect of the filter element body can be further improved.

Owner:新昌县大菠萝农业发展有限公司

Cleaning device

InactiveCN112642763AImprove securityAvoid mixingCleaning using toolsCleaning using gasesThermodynamicsCombustion

The invention discloses a cleaning device. The cleaning device comprises a support, a cleaning unit, a sealing unit, a first driving unit and a control unit; the cleaning unit comprises a dust collection component and a dust collection box, and the dust collection box is fixed to the support; the sealing unit is used for sealing a furnace opening of a furnace body, and the dust collection component is arranged on the sealing unit; and the first driving unit is fixed to the support and used for driving the sealing unit to move to seal the furnace opening, the dust collection component moves along with the sealing unit to extend into a furnace cavity, and the control unit is used for controlling the first driving unit. The cleaning device can provide a closed environment for cleaning of the inner cavity of the furnace body, safety risks such as combustion or explosion caused by the fact that dust in the furnace cavity falls off and is mixed with air in the cleaning process are avoided, the cleaning safety is improved, cleaning is comprehensive and thorough, labor consumption is reduced, the cleaning effect is good, and the cleaning efficiency is high.

Owner:SICC CO LTD

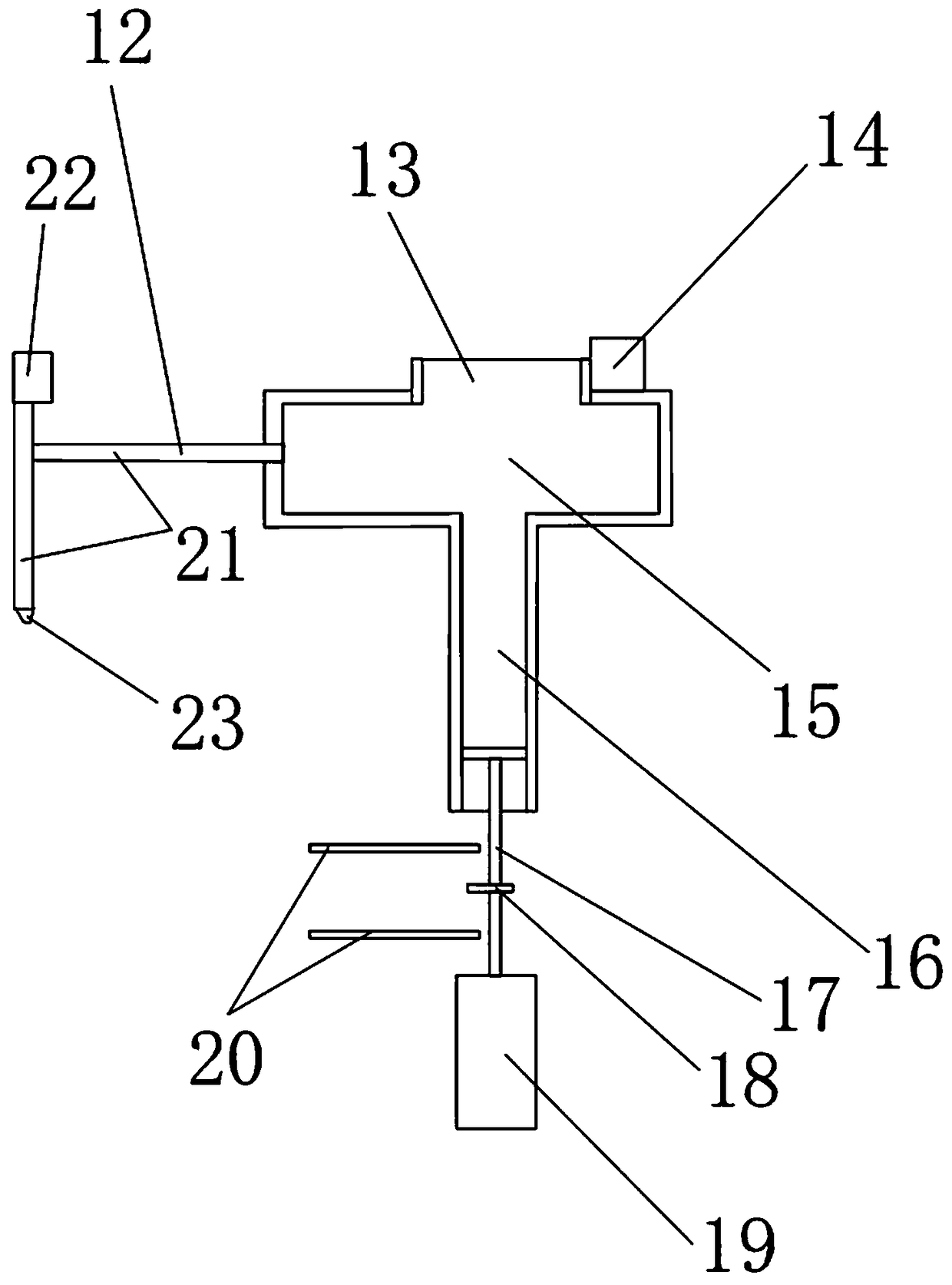

Epitaxial slice cleaning device

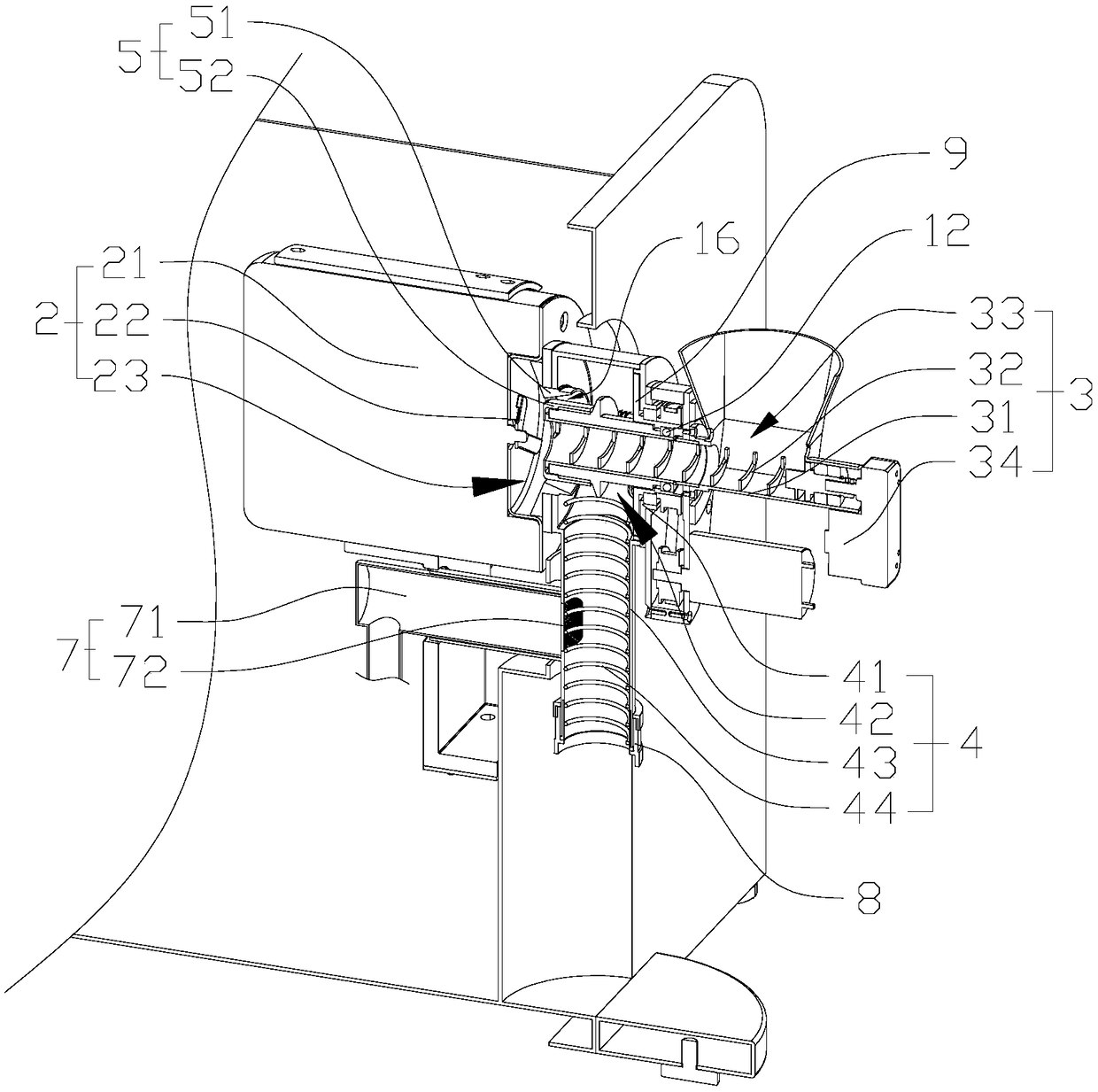

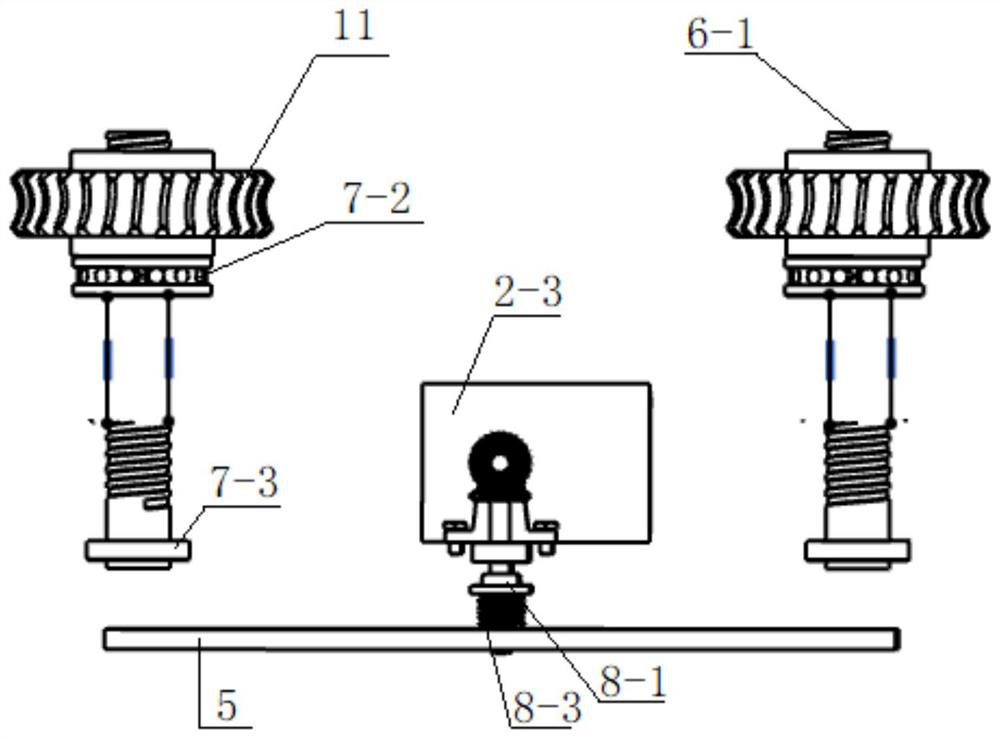

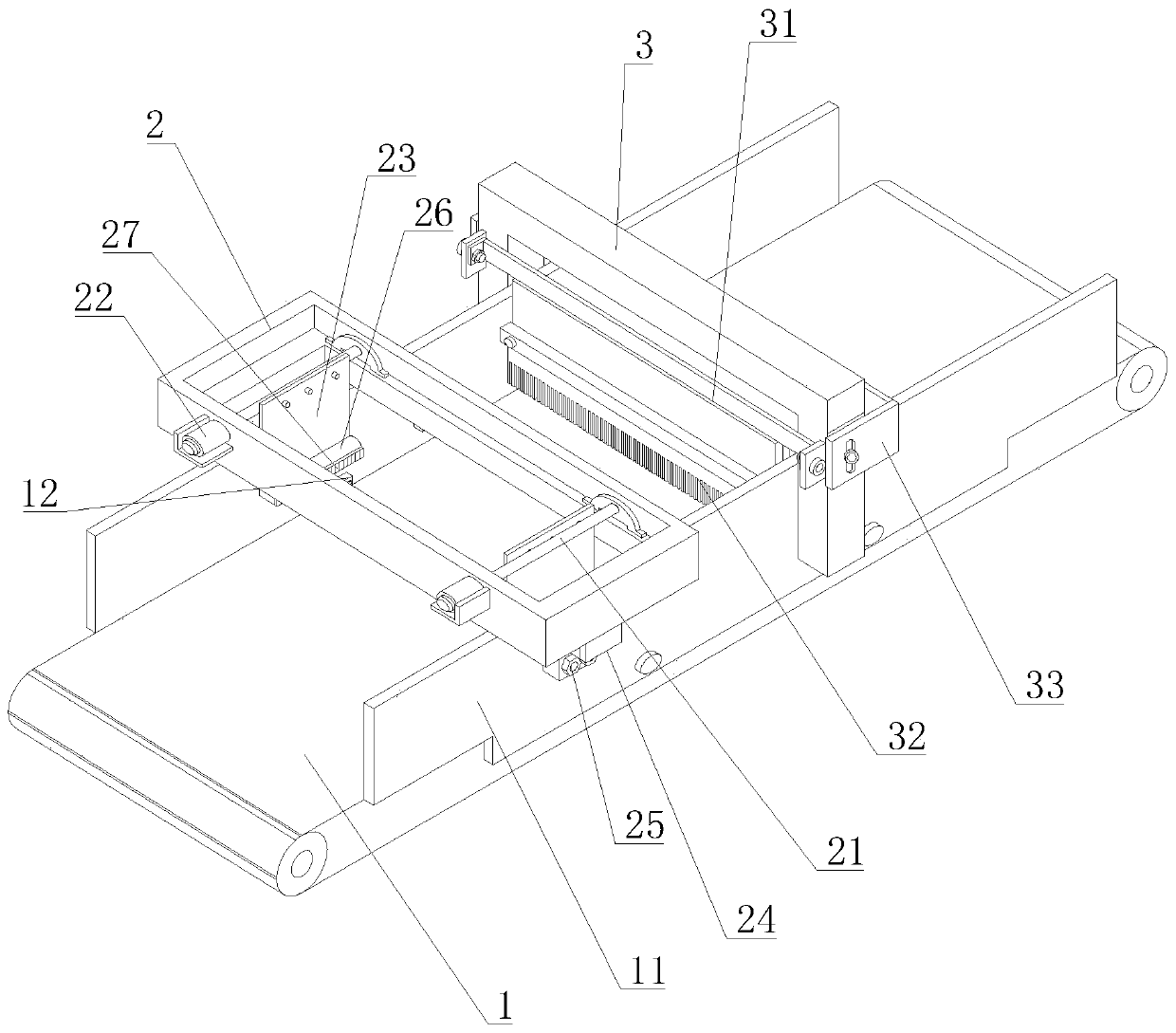

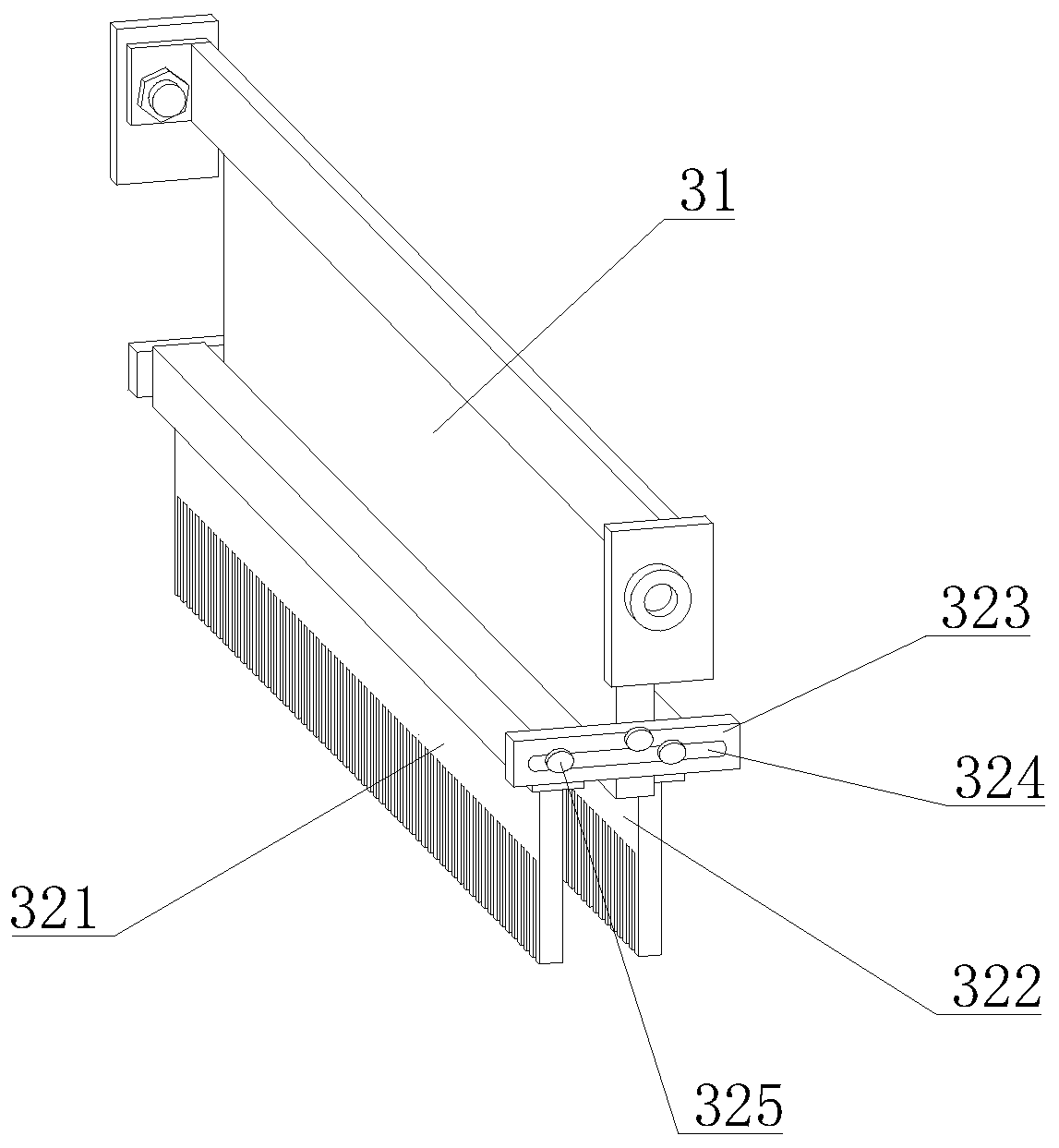

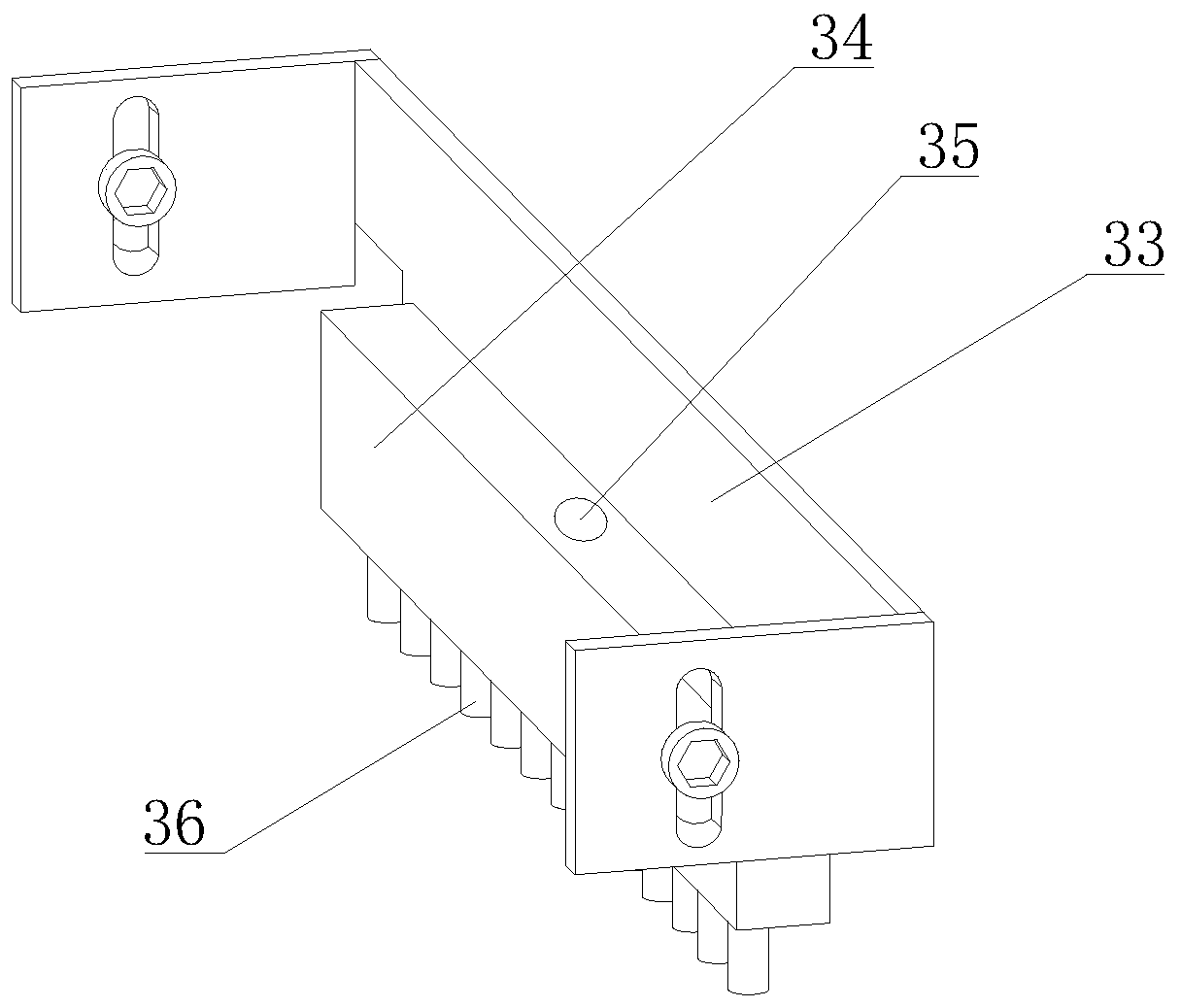

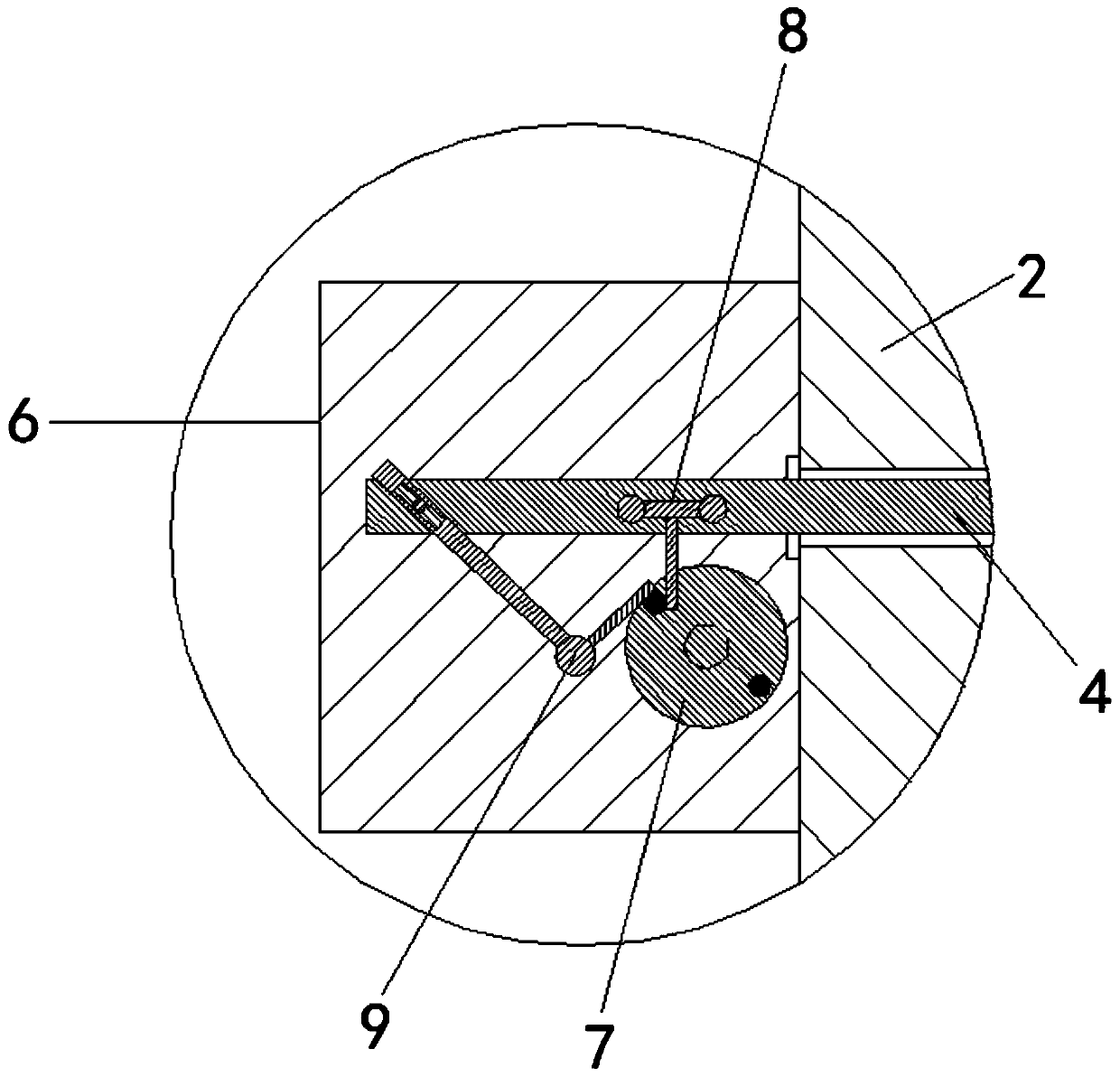

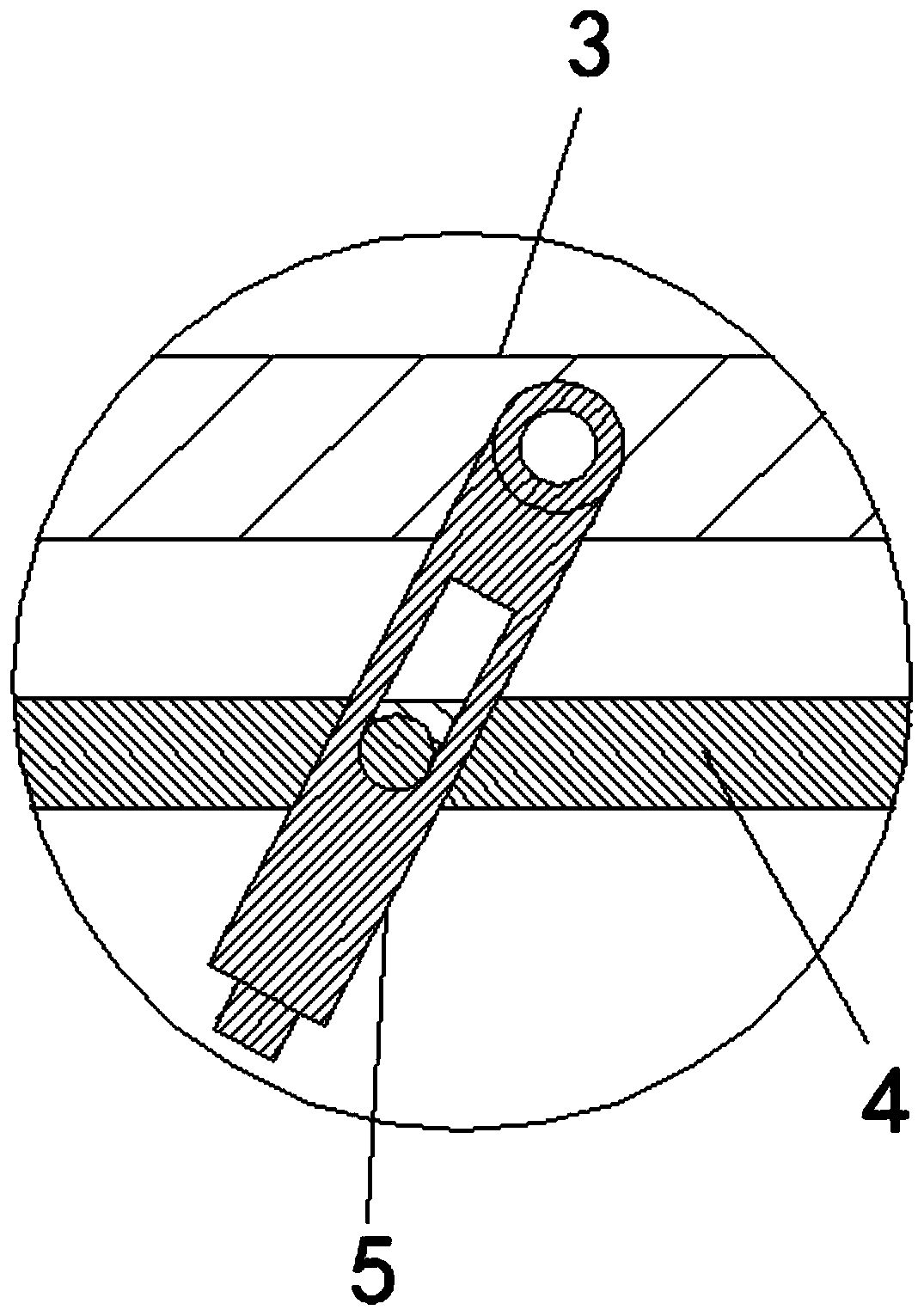

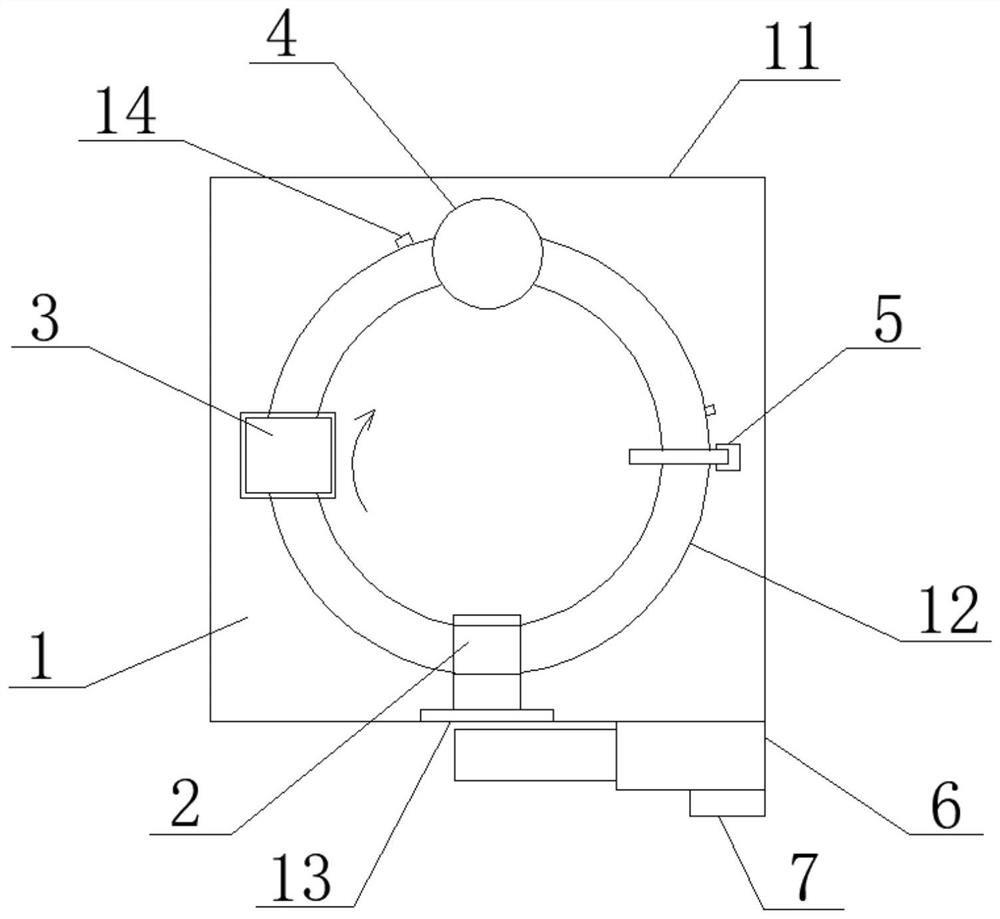

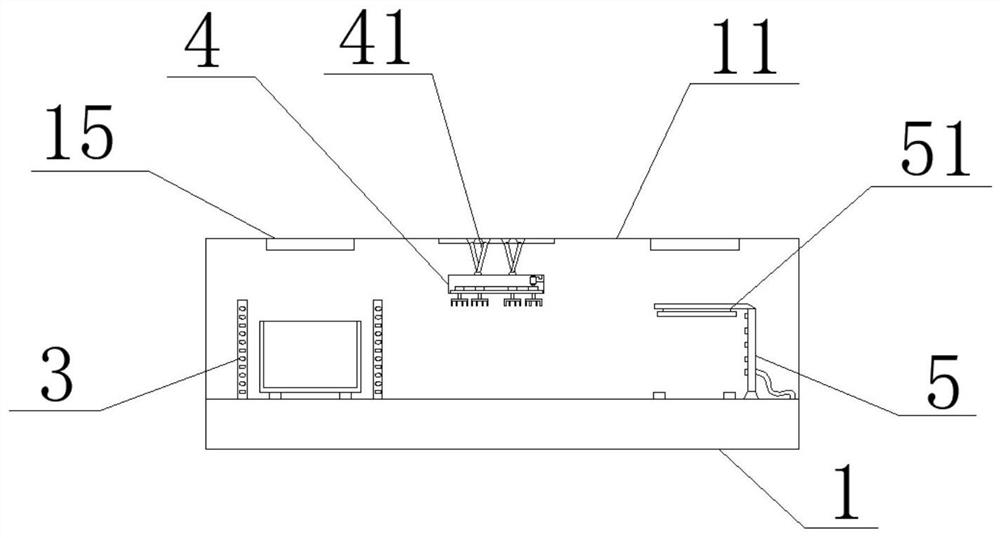

ActiveCN113245275AClear in timeReduce cleaning dead spaceDrying gas arrangementsCleaning using liquidsEngineeringScrew thread

The invention discloses an epitaxial slice cleaning device. The epitaxial slice cleaning device comprises a cleaning tank, a slide frame, a cleaning mechanism, a rotating mechanism and a drying mechanism, wherein the cleaning tank is equipped with a partition plate for dividing the cleaning tank into a primary cleaning region and a fine cleaning region; lead screws are arranged at the tops at the two sides of the cleaning tank; the slide frame capable of sliding on the cleaning tank is arranged on the lead screws; slide blocks placed on the lead screws are arranged at the two ends of the slide frame; threads are processed on the bottom surfaces of the slide blocks; the cleaning mechanism is arranged above the slide frame; the rotating mechanism is arranged below the slide frame; and one end, away from the primary cleaning region, of the fine cleaning region is equipped with the drying mechanism. The lead screws are arranged on the cleaning tank, the slide frames are arranged on the lead screws, and the rotating lead screws drive the slide frames to move; the cleaning device mounted on the cleaning tank cleans an epitaxial slice on the slide frames, and is matched with the rotating mechanism to drive the epitaxial slice to rotate on the slide frames, so that a cleaning dead corner is reduced, and cleaning quality is guaranteed; and the epitaxial slice cleaning device can be matched with the drying device for timely clearing water spots left on the epitaxial slice, so that secondary pollution is avoided.

Owner:四川雅吉芯电子科技有限公司

PCB (Printed Circuit Board) visual inspection equipment

PendingCN113686896AEasy to cleanReduce the risk of detection point coveragePreparing sample for investigationMaterial analysis by optical meansVisual inspectionGas passing

The invention relates to the field of SMT (Surface Mount Technology) processing inspection equipment, in particular to PCB (Printed Circuit Board) visual inspection equipment, which comprises a frame body, a first track plate, a second track plate and a visual inspection device. A channel for a PCB to pass through is reserved between the first track plate and the second track plate. Conveying rails are arranged on opposite plate surfaces of the first track plate and the second track plate, and are used for conveying a PCB to a detection position of the visual detection device. The opposite surfaces of the first track plate and the second track plate are respectively provided with an impurity inlet and a gas outlet which are oppositely arranged. The frame body is provided with a gas bag. The gas bag is provided with an electromagnetic pulse valve for gas to flow out. An outlet pipeline of the electromagnetic pulse valve is connected to the gas outlet. The gas in the gas bag flows into the gas outlet through the electromagnetic pulse valve, and the gas is guided by the gas outlet to blow impurities attached to the surface of the PCB into the impurity inlet. By adoption of the PCB visual inspection equipment, the problem that the detection precision of a PCB is affected by impurities is solved.

Owner:深圳市中纬智能有限公司

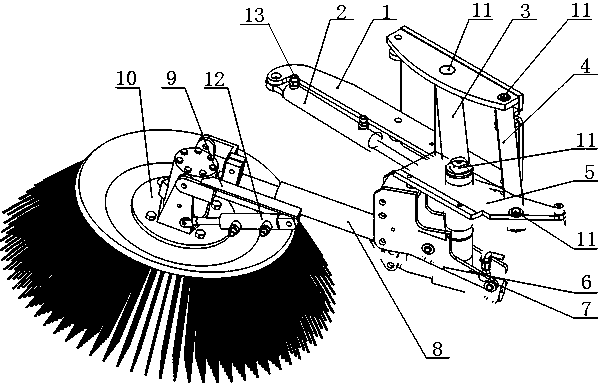

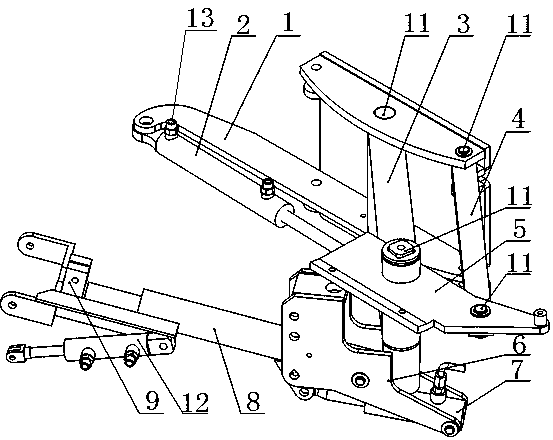

Mechanical arm type side brush mechanism

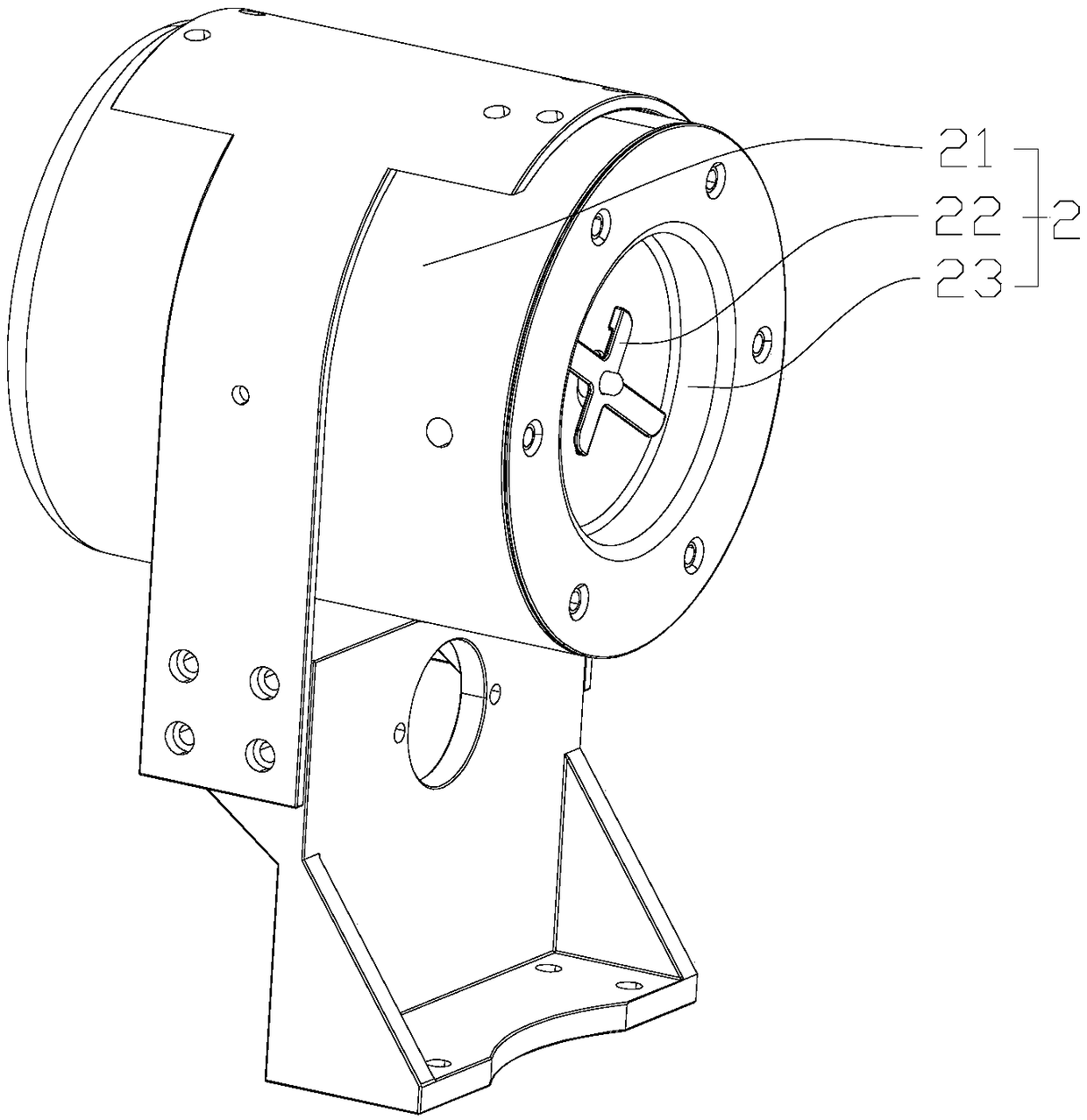

InactiveCN108774982AImprove working conditionIncrease the cleaning areaRoad cleaningHydraulic cylinderAgricultural engineering

The invention provides a mechanical arm type side brush mechanism. The mechanical arm type side brush mechanism comprises a main fixing plate; a main hydraulic cylinder is arranged on the main fixingplate; one end of the main hydraulic cylinder is connected to the main fixing plate; a connecting rotating arm is arranged at the other end of the main hydraulic cylinder; a sub connecting rotating arm is also arranged on the main fixing plate; a swinging arm fixing block is arranged beside the sub connecting rotating arm; a swinging arm rotating block is arranged at the lower end of the connecting rotating arm; a sub hydraulic cylinder is arranged on the swinging arm rotating block; a telescopic rod is arranged at the front end of the sub hydraulic cylinder; a side brush fixing plate is arranged at the front end of the telescopic rod; and a side brush is fixed on the side brush fixing plate. Through an operation device, the sub hydraulic cylinder works so that the distance between the telescopic rod and the ground and the distance between the side brush and the ground can be regulated; and therefore, the side brush is in an optimal working state; through the operation device, the mainhydraulic cylinder works so that the swinging arm fixing block and the side brush can be driven to move within a certain range; and therefore, the sweeping area of the side brush is increased, the sweeping dead corner is reduced, and the sweeping range is enlarged so that the sweeping efficiency is enhanced.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

Desk lamp capable of automatically removing dust based on voice recognition

InactiveCN110953500AEasy to open and closeEasy to control opening and closingElectric circuit arrangementsLighting elementsDust controlSpeech sound

The invention discloses a desk lamp capable of automatically removing dust based on voice recognition. The desk lamp comprises a supporting table, a supporting device is arranged on the supporting table; the supporting device comprises a fixing rod fixedly arranged on the upper end face of the supporting table. The upper end of the fixing rod is fixedly arranged on a fixed block; inserting holes with upward openings are symmetrically formed in the left and right positions of the upper end surface of the fixed block; supporting columns capable of sliding up and down are arranged in the inserting holes; a brightness adjusting device is arranged in the supporting table; a first dust removal device is arranged on the upper side of the supporting device; a second dust removal device is arrangedbelow the first dust removal device; according to the invention, the on-off of the desk lamp can be conveniently controlled and the brightness of the desk lamp can be adjustedthrough voice recognition; when voice control is not convenient, disturbance to other people can be avoided through manual control of a rotary knob, dust accumulated on the outer surface of a lampshade and in the lampshade of the desk lamp can be automatically removed, cleaning dead corners are small, dust can be cleaned up without manual disassembly, disassembly is convenient, and a bulb is convenient to replace.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

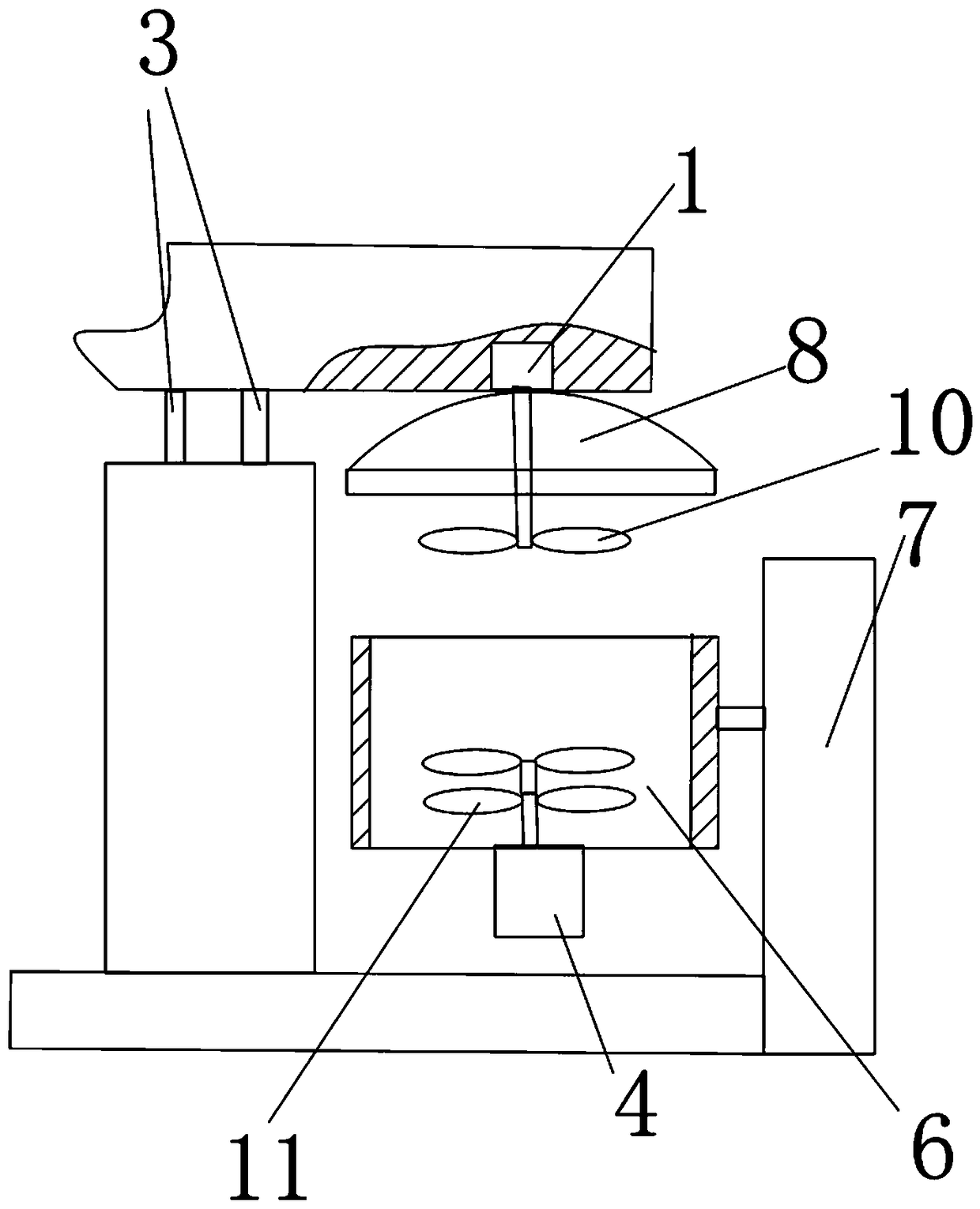

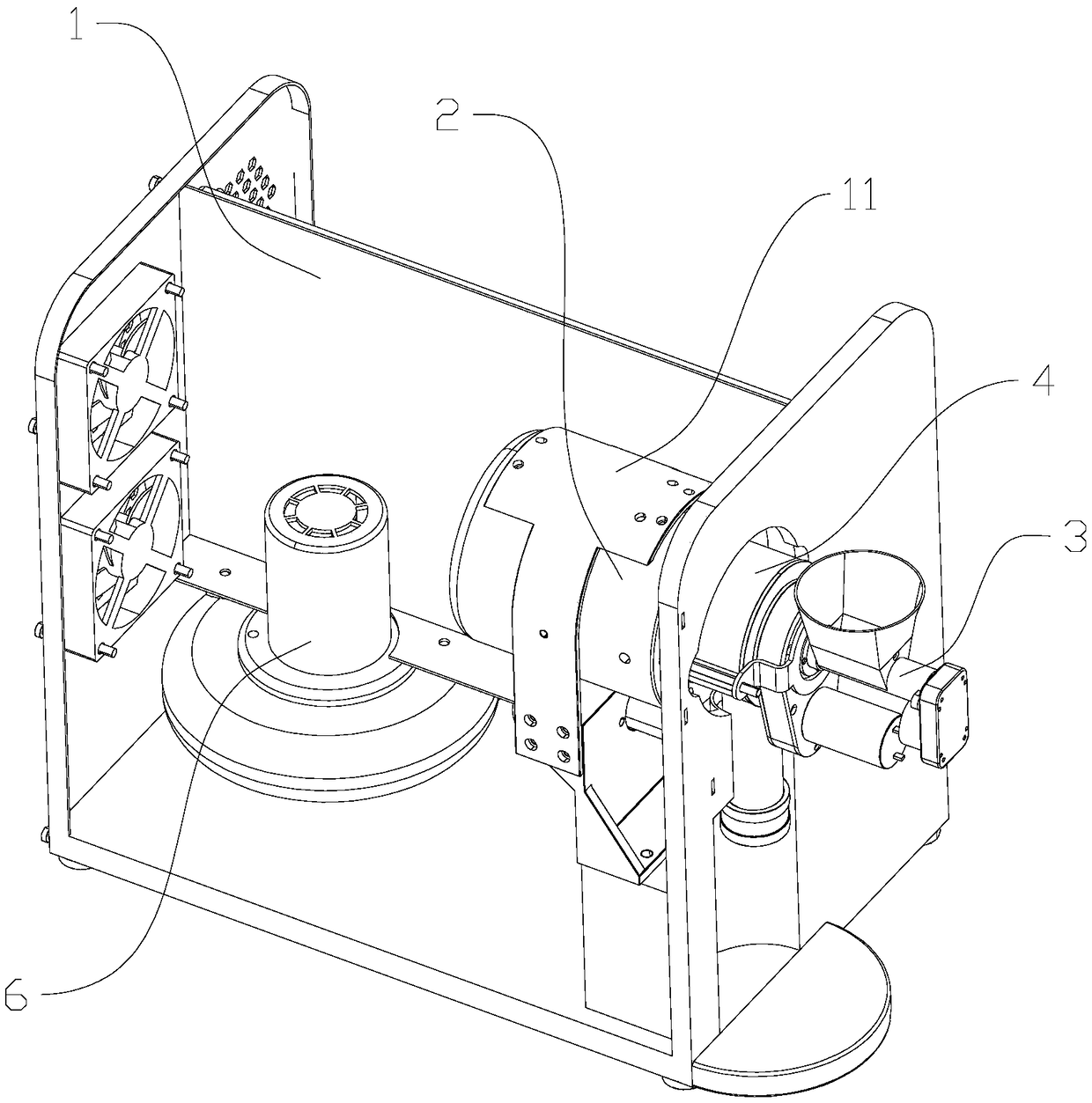

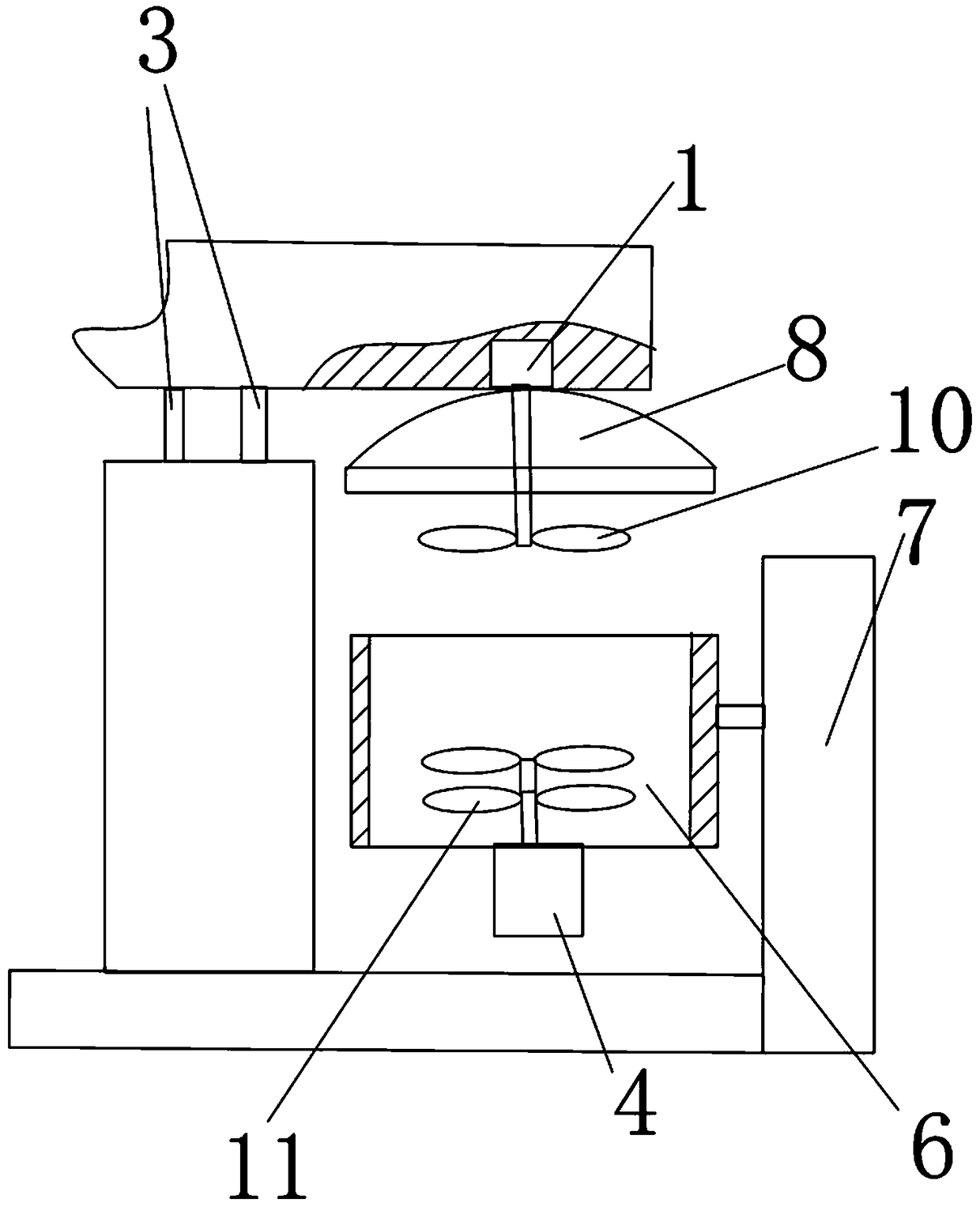

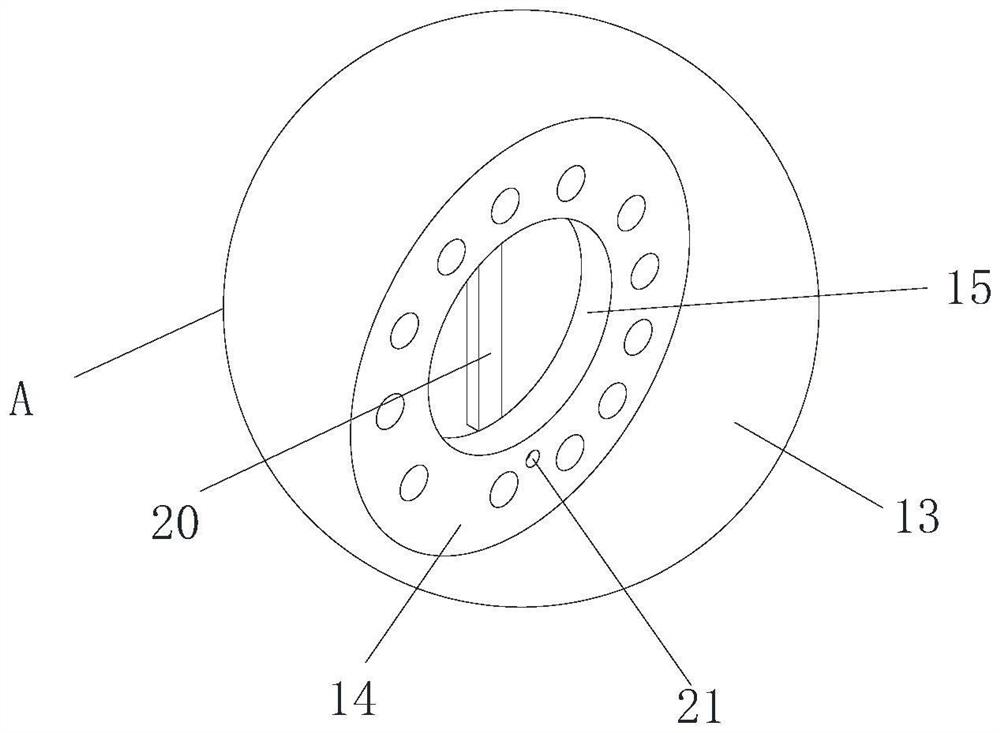

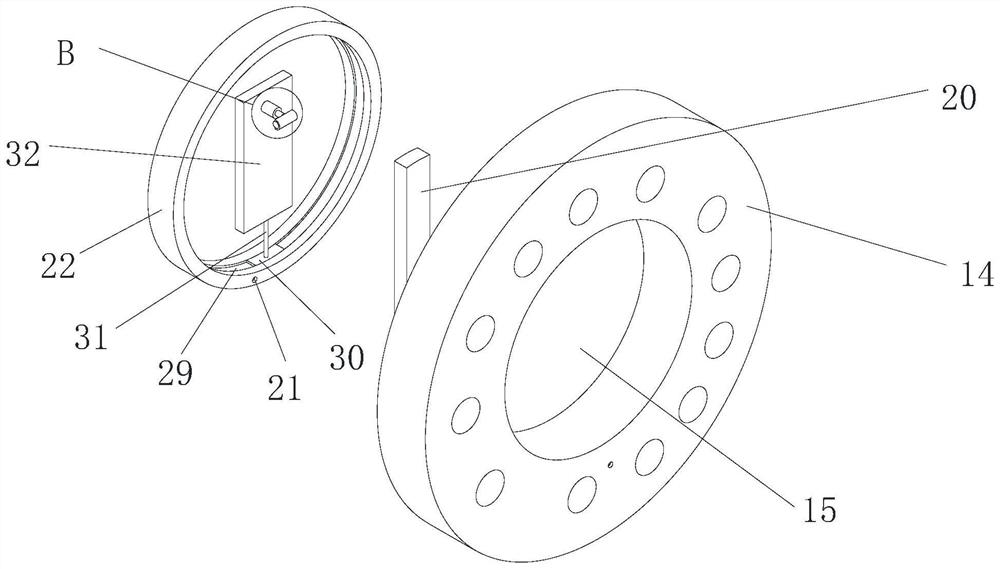

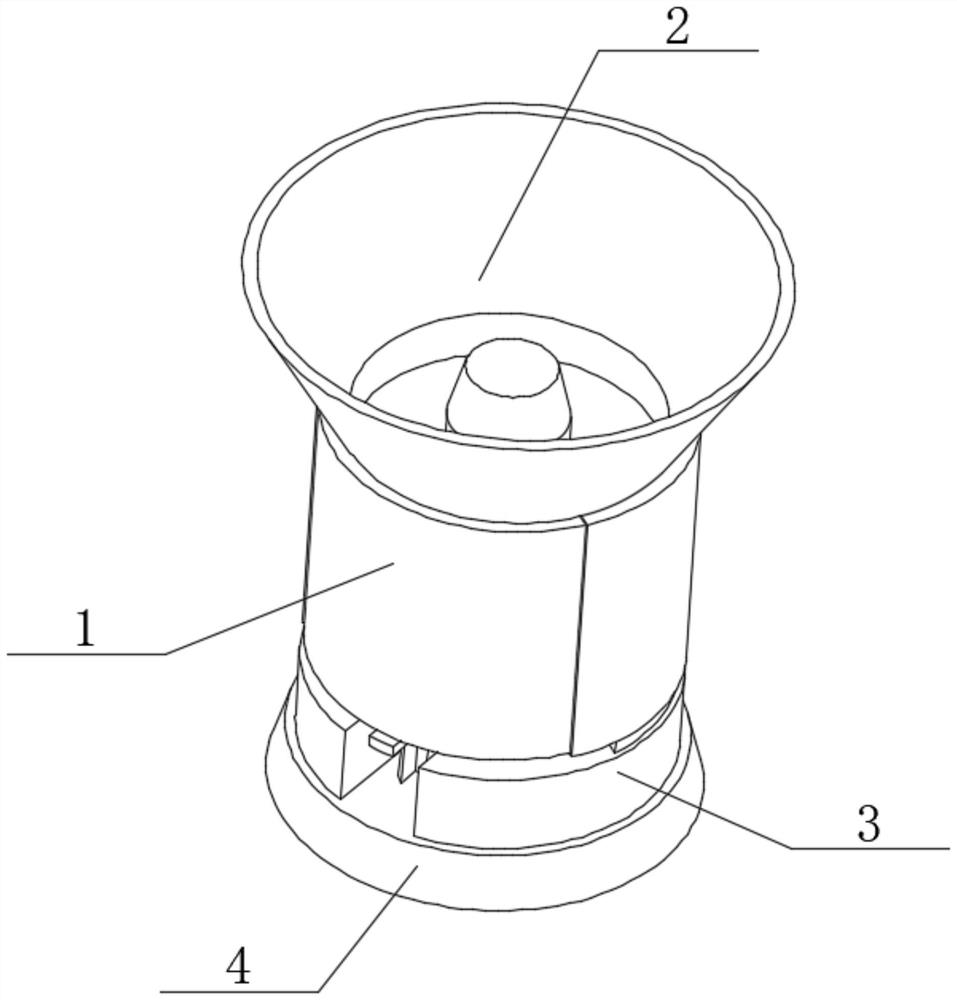

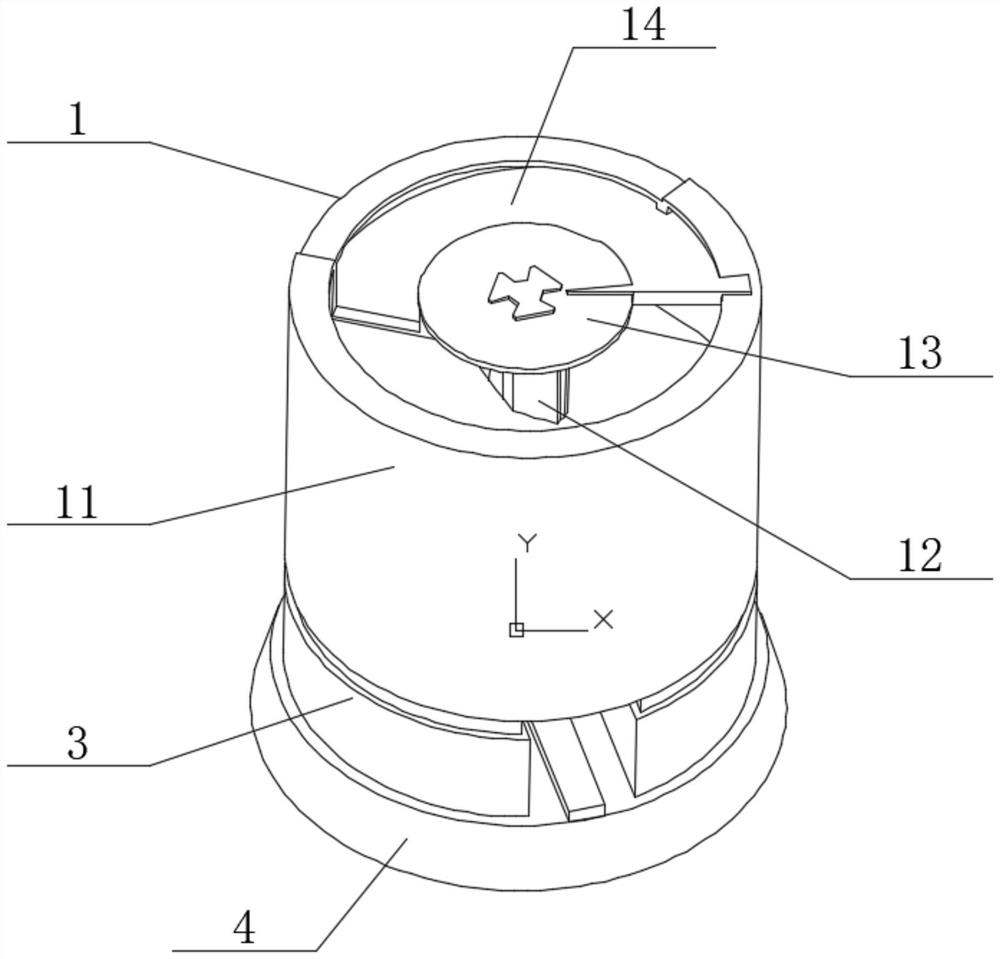

Small ultrafine grinder with self-cleaning mechanism

The invention discloses a small ultrafine grinder with a self-cleaning mechanism. The small ultrafine grinder comprises a grinding device, the grinding device includes a grinding cavity, grinding blades and a grinding motor, the grinding cavity is connected with a material collection box and a feeding channel, the feeding channel penetrates the material collection box and communicates with the grinding cavity, a transition channel is arranged on the side, close to the grinding cavity, of the feeding channel and the material collection box, a rotary table is rotatably arranged on the one side,away from the grinding cavity, of the material collection box, and a cleaning brush is arranged on the rotary table. The material collection box is further connected with a discharging channel which is internally provided with a cleaning spring, and the cleaning spring is arranged in the discharging channel in a sliding and / or rotating mode. The rotary table rotatably arranged drives the cleaningbrush to clean the interior of the material collection box, a user cleans traditional Chinese medicine powder attached in the discharging channel by the cleaning spring, the user can quickly clean theresidual traditional Chinese medicine powder in the small ultrafine grinder by improving the convenience of cleaning the small ultrafine grinder, and the efficiency of Chinese medicinal material preparation is improved.

Owner:南京同仁堂乐家老铺健康科技有限公司 +1

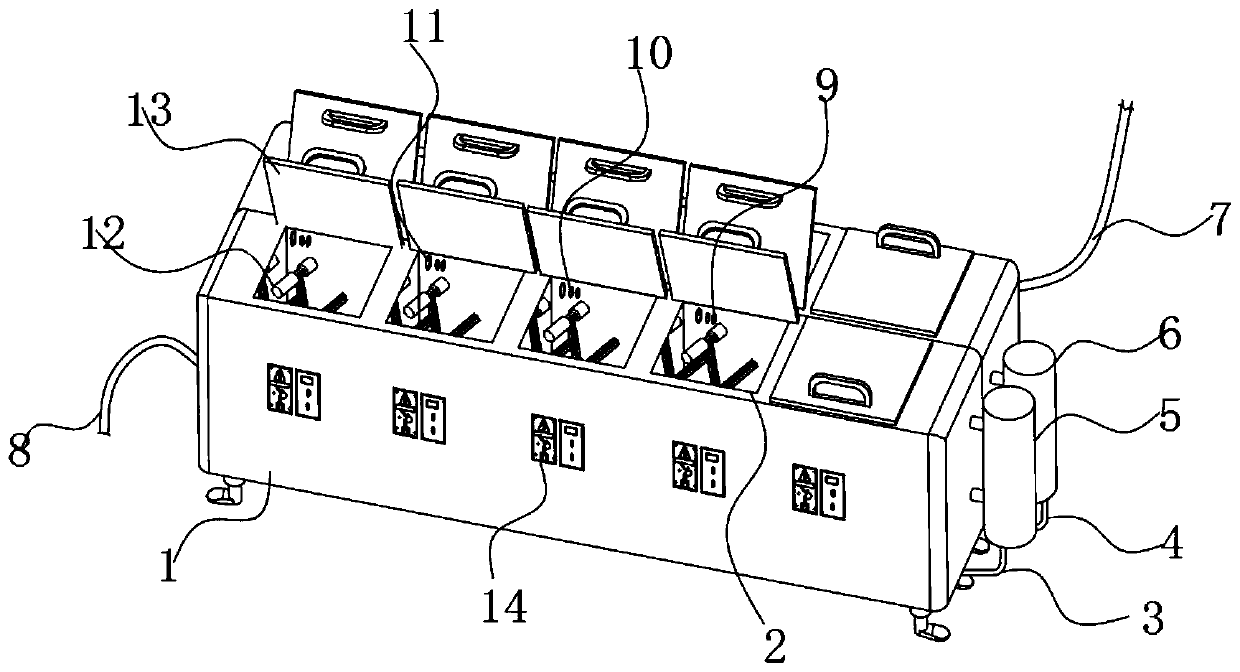

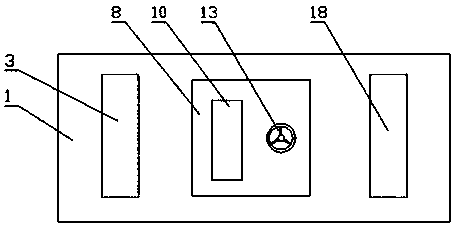

Novel college dormitory coin-operated rapid shoe washing machine

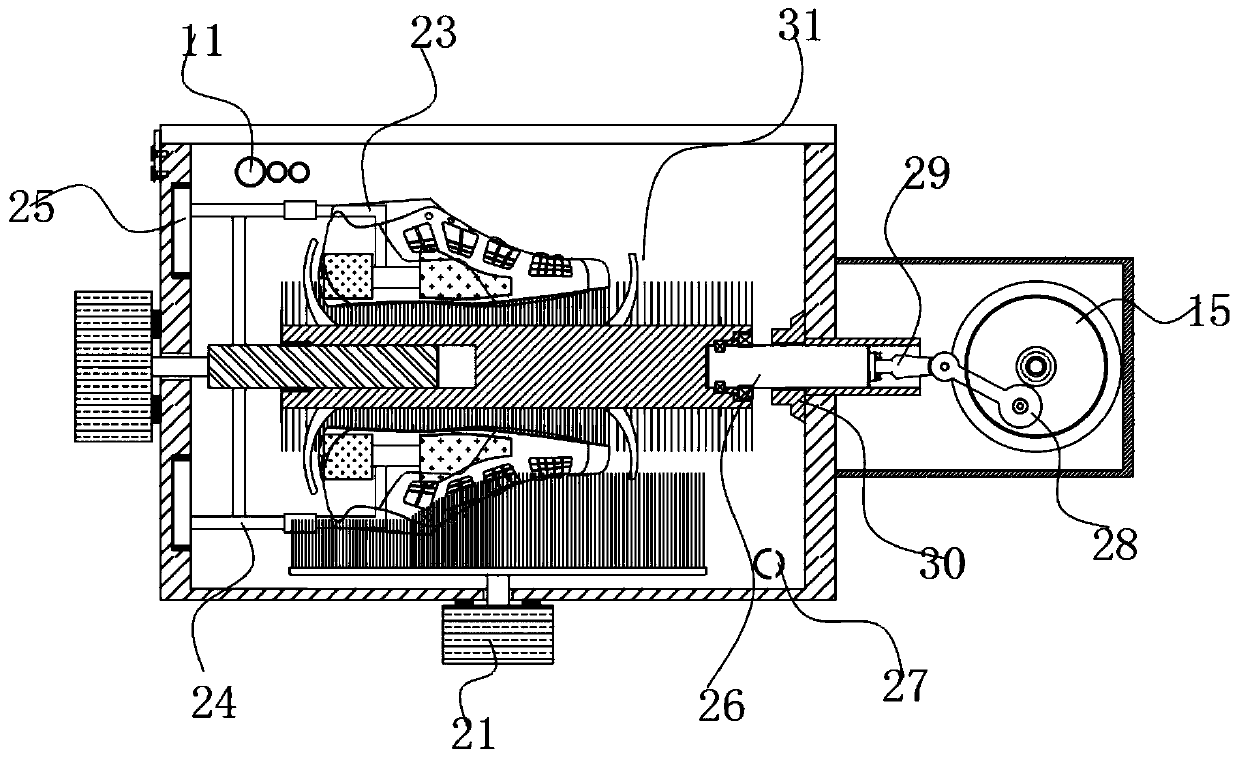

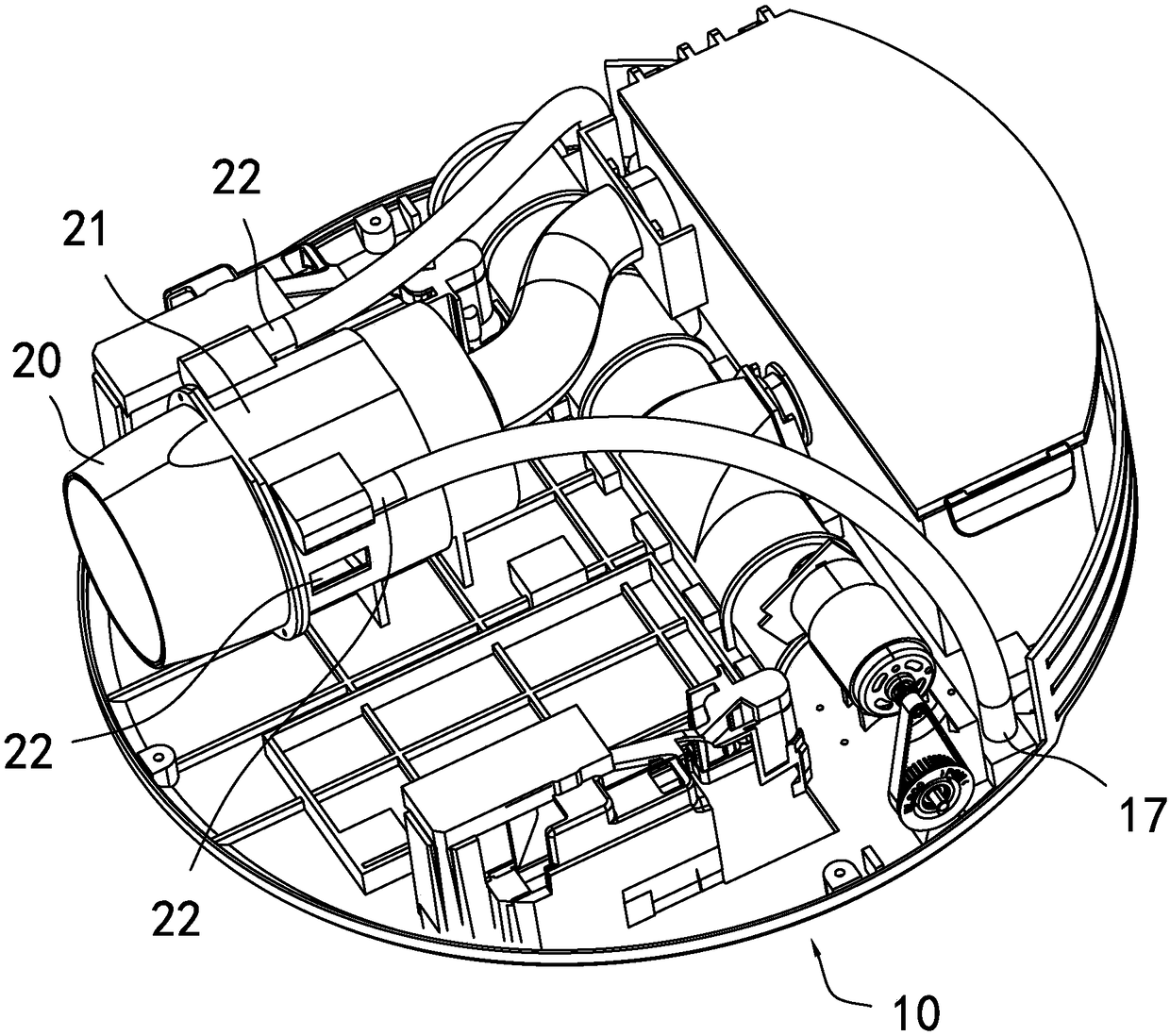

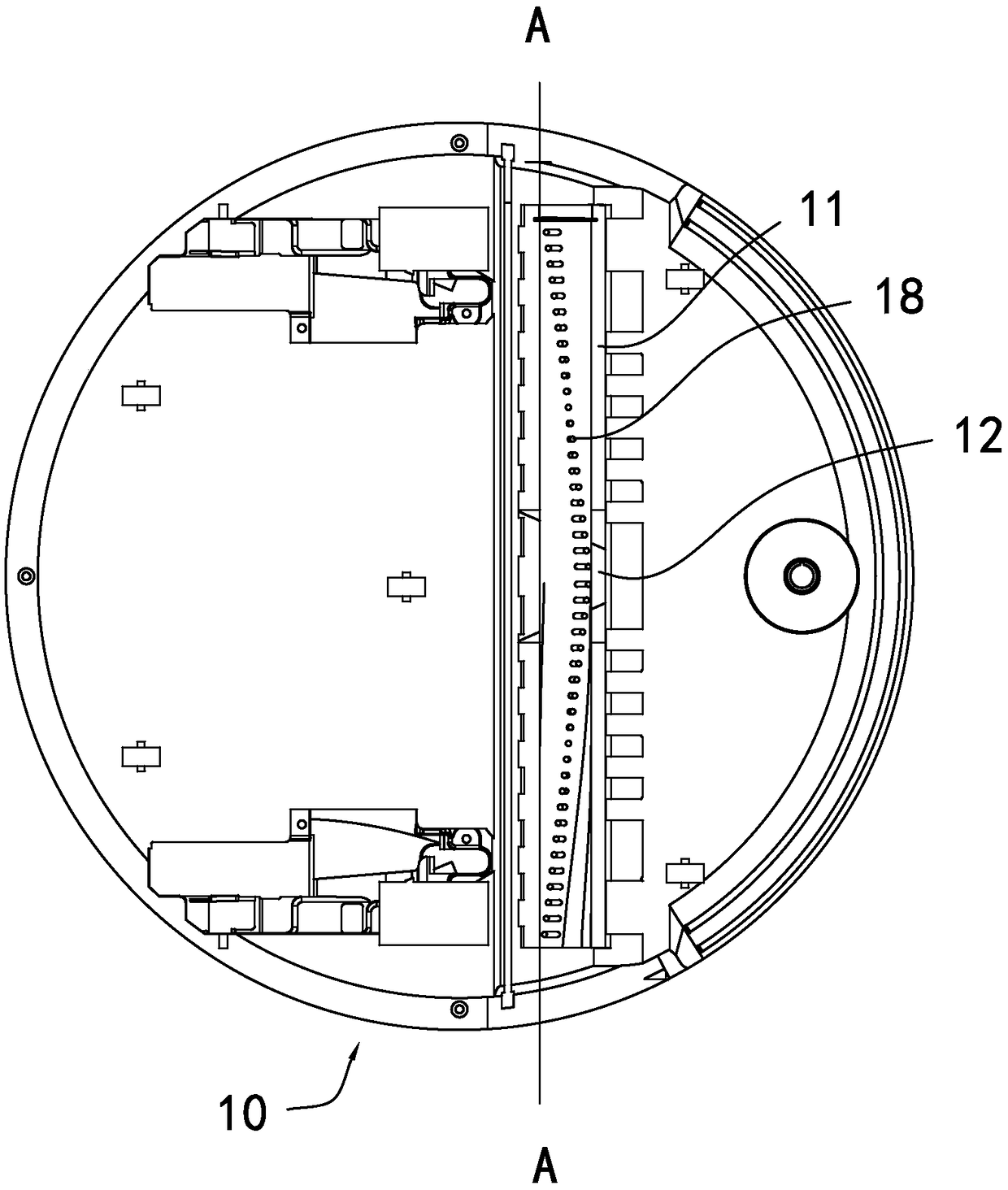

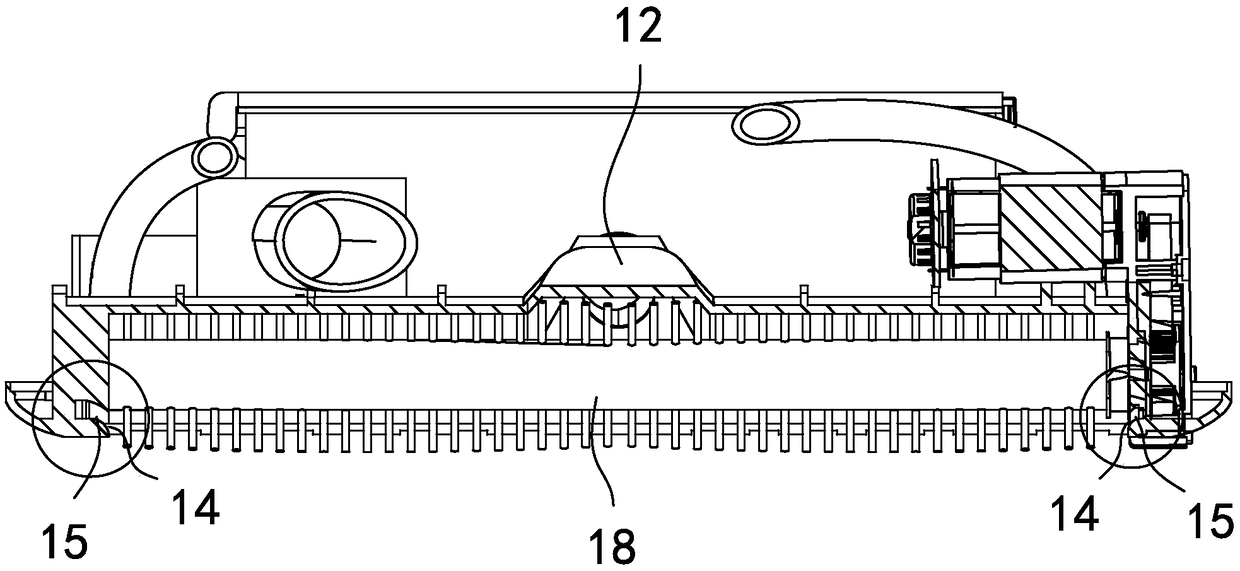

ActiveCN111528758AReduce cleaning dead spaceImprove cleanlinessApparatus for meter-controlled dispensingFootwear cleanersExternal LiquidStructural engineering

The invention discloses a novel college dormitory coin-operated rapid shoe washing machine. The shoe washing machine comprises a shell and a shoe washing box, and the shoe washing box is arranged in the shell. An external liquid supply assembly supplies water and liquid to the shoe washing box, a cleaning assembly is further arranged in the shoe washing box and comprises a follow-up limiting assembly, a push-pull cleaning assembly and a vamp cleaning assembly, and the push-pull cleaning assembly at least comprises a supporting cleaning column capable of sliding back and forth in the horizontaldirection. The vamp cleaning assembly comprises a driving square rod capable of driving the supporting cleaning column to rotate at equal angles and a surface cleaning brush capable of rotating alongthe vertical axis. The follow-up limiting assembly can limit the shoes on the brushes of the supporting and cleaning column and enable the shoes to rotate at equal angles along with the supporting and cleaning column, so that the shoes are sequentially rotated to the positions above the surface cleaning brushes, the surfaces of the shoes are cleaned conveniently, and cleaning dead corners are reduced.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Floor brush assembly and floor sweeping robot

The invention discloses a floor brush assembly and a floor sweeping robot, wherein the floor brush assembly comprises a floor brush body, wherein the floor brush body is provided with a floor brush inner cavity and a floor brush suction opening communicated with the floor brush inner cavity; a rolling brush arranged in the floor brush inner cavity; and an air outlet which is arranged on at least one side of the left side and right side of the floor brush suction opening and can be used for introducing air flow for raising dust at the floor brush suction opening, wherein by arranging the air outlet at the side of the floor brush, the dust is raised and gathered by utilizing the blowing air flow, and the air outlet is matched with the rolling brush, so that the dust collection capacity is effectively improved; in addition, due to the existence of the air outlet, the length of the ground brush suction opening can be longer under the condition of not reducing the dust removal capacity, thedead angle is smaller in a cleaning process, an additional side brush is not needed, the cost is lower, and the space is saved.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

Textile cloth cover unhairing device

InactiveCN105839380AReduce cleaning dead spaceImprove surface qualityMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention relates to the textile field, and particularly relates to a textile cloth cover unhairing device. The textile cloth cover unhairing device can also remove stains such as oil stains and the like on a piece of cloth while thoroughly removing thread residues and naps at the surface of the cloth. The textile cloth cover unhairing device structurally comprises a base plate and is characterized in that a winding drum is fixed at the upper surface of the base plate through a first bracket; one side of the winding drum is provided with a box body, and the box body is of a cuboid structure; one side of the box body is provided with an electric winding drum, and the electric winding drum is fixed at the upper surface of the base plate through a second bracket; two side walls of the box body are provided with a feed port and a discharge port respectively, and the feed port and the discharge port are rectangular openings; the upper surface of the box body is provided with a high-voltage compartment, and the high-voltage compartment is of a cuboid hollow structure; and the high-voltage compartment is connected with a nozzle in the box body through an output pipe. The textile cloth cover unhairing device is convenient and efficient in use, low in use cost, and applicable to removing thread residues and naps at the cloth surface.

Owner:WUJIANG YUANTONG TEXTILE

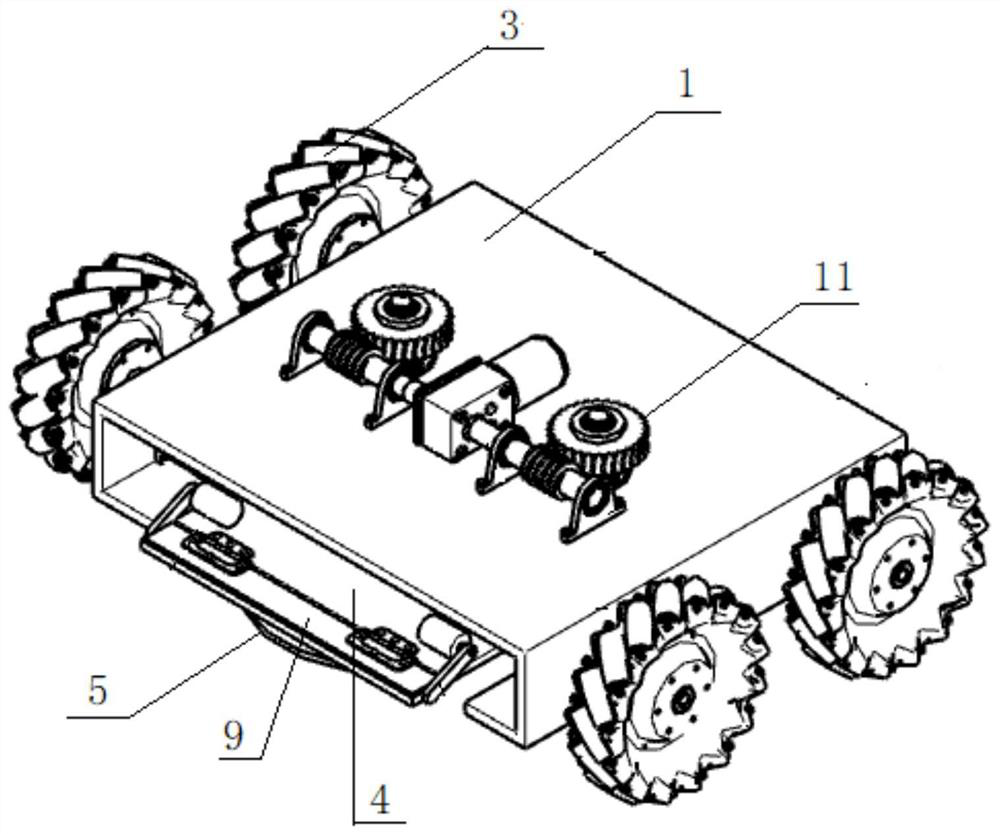

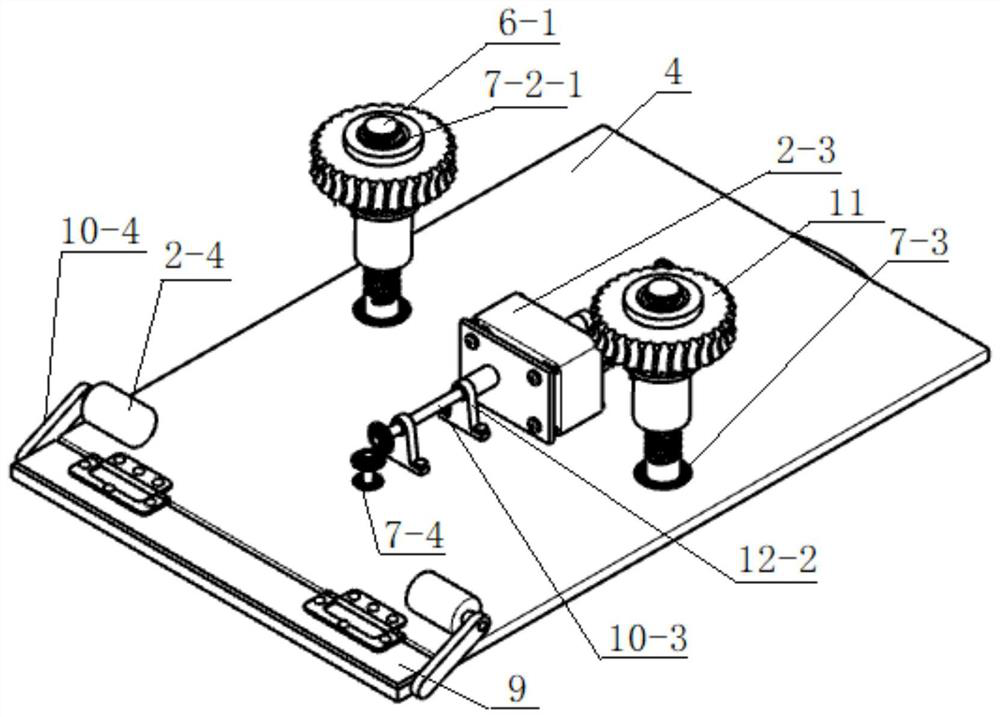

Pressurized mopping robot and working method thereof

PendingCN111714044APrevent leavingPrecise positioningCarpet cleanersFloor cleanersControl engineeringElectric machinery

The invention discloses a pressurized mopping robot and a working method thereof, and belongs to the technical field of intelligent robots. A robot body comprises a main body, a walking mechanism, a lifting plate and a dragging plate. The main body is connected with the walking mechanism, a lifting plate motor and a worm and gear mechanism are arranged on the main body, the lifting plate motor isconnected with a worm of the worm and gear mechanism, a worm gear of the worm and gear mechanism is in threaded connection with a first lead screw, and the first lead screw penetrates through the mainbody and is fixedly connected with the lifting plate; a carriage motor is arranged on the lifting plate, the carriage motor is connected with the carriage through a transmission mechanism, and a spring device is arranged between the transmission mechanism and the carriage; the charging and cleaning device comprises a shell, a water tank and a cleaning basin, the shell is connected with the watertank, the water tank is connected with the cleaning basin, the cleaning basin is detachably fixed below the shell, and a sensing device and a charging device are arranged on the shell. Certain pressure can be applied to the ground during mopping, so that the mopping effect is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Wood block surface cleaning and counting device

InactiveCN111054673AGuaranteed drynessNot easy to stainCleaning using toolsCounting mechanisms/objectsRotational axisSurface cleaning

The invention discloses a wood block surface cleaning and counting device, comprising a conveyor, wherein baffles are arranged on the two sides of the conveyor; a mounting frame and a gantry support are sequentially arranged on each baffle in a conveying direction; a pair of rotating shafts parallel to the conveying direction are arranged on the inner two sides of each mounting frame; one ends ofthe rotating shafts are rotationally connected with the mounting frames; the other ends of the rotating shafts are connected with rotating motors; adjusting plates are arranged on the inner sides of the rotating shafts; a first support is arranged on the front side of the gantry support; double cleaning brushes are arranged at the lower end of the first support; a second support is arranged on therear side of the gantry support; a hollow mounting frame is arranged at the lower end of the second support; an air inlet is formed in the top end of the mounting frame; an air spraying pipe is arranged at the bottom of the mounting frame; and a photoelectric switch counter is arranged on the bottom face of the gantry support. The device has the characteristics of thorough and comprehensive cleaning and accurate counting.

Owner:湖州南浔锦鸿木业有限公司

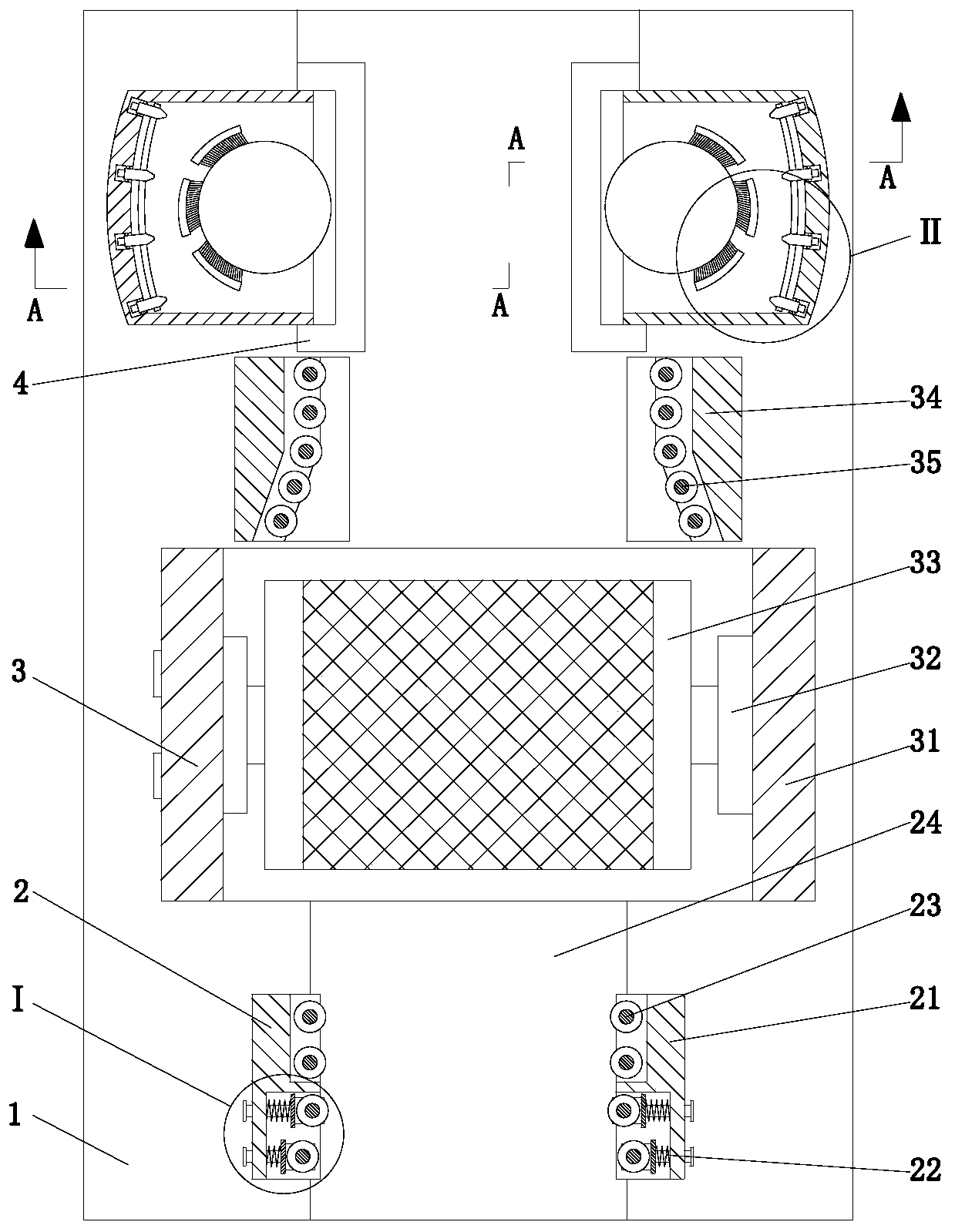

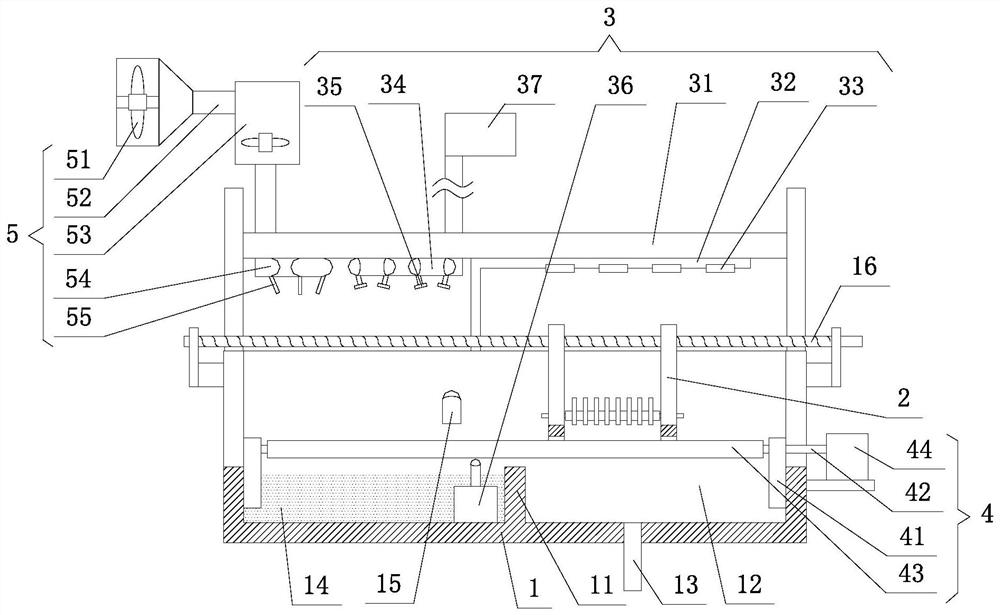

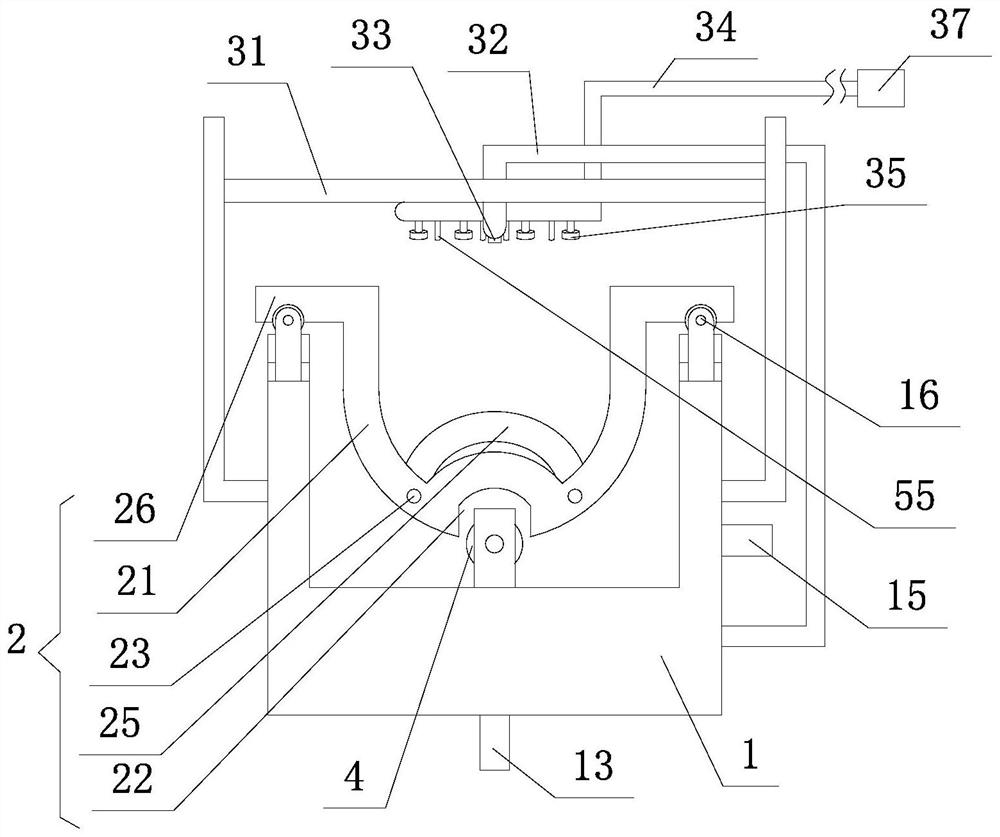

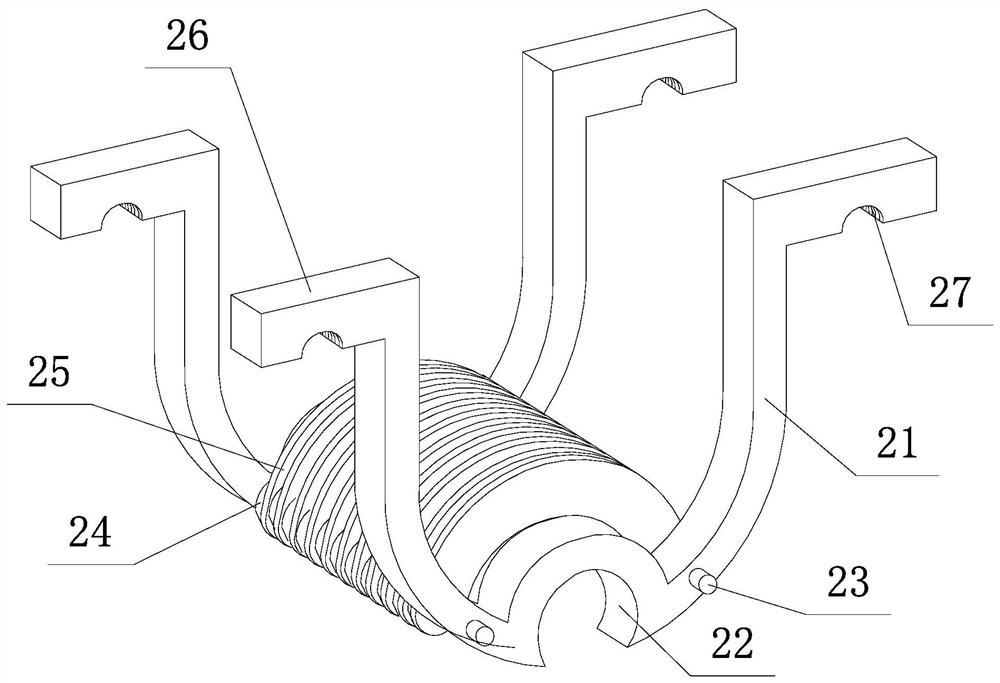

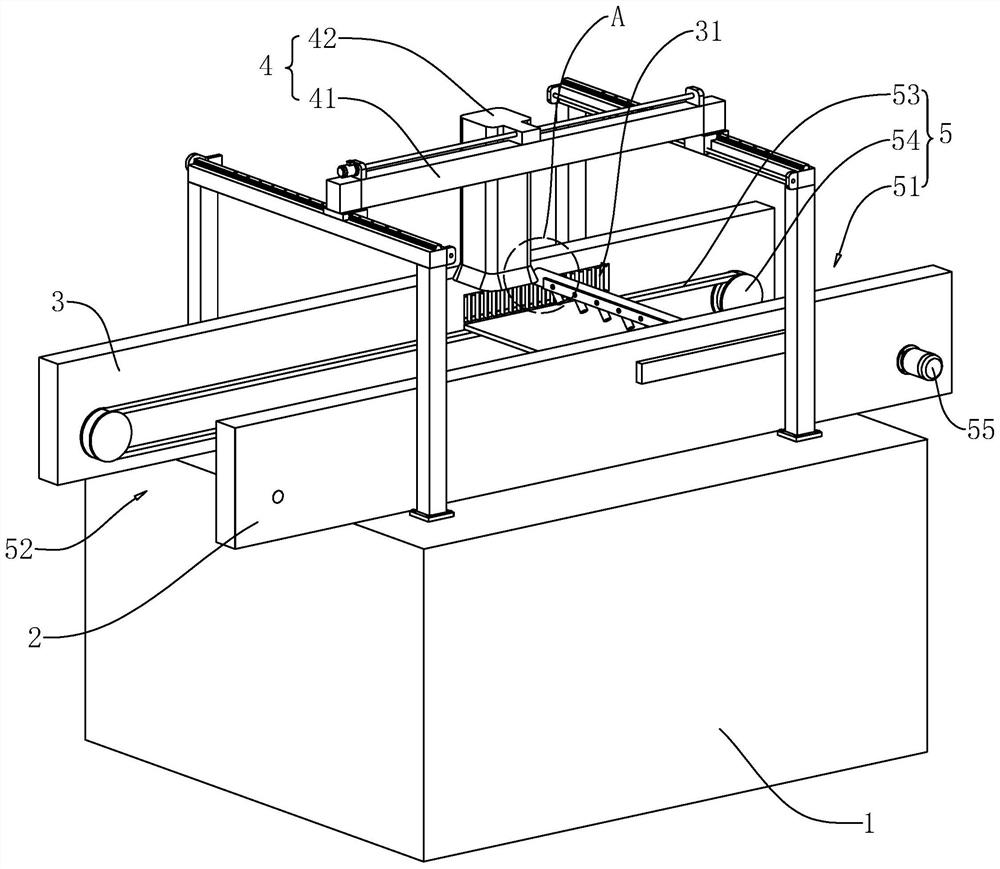

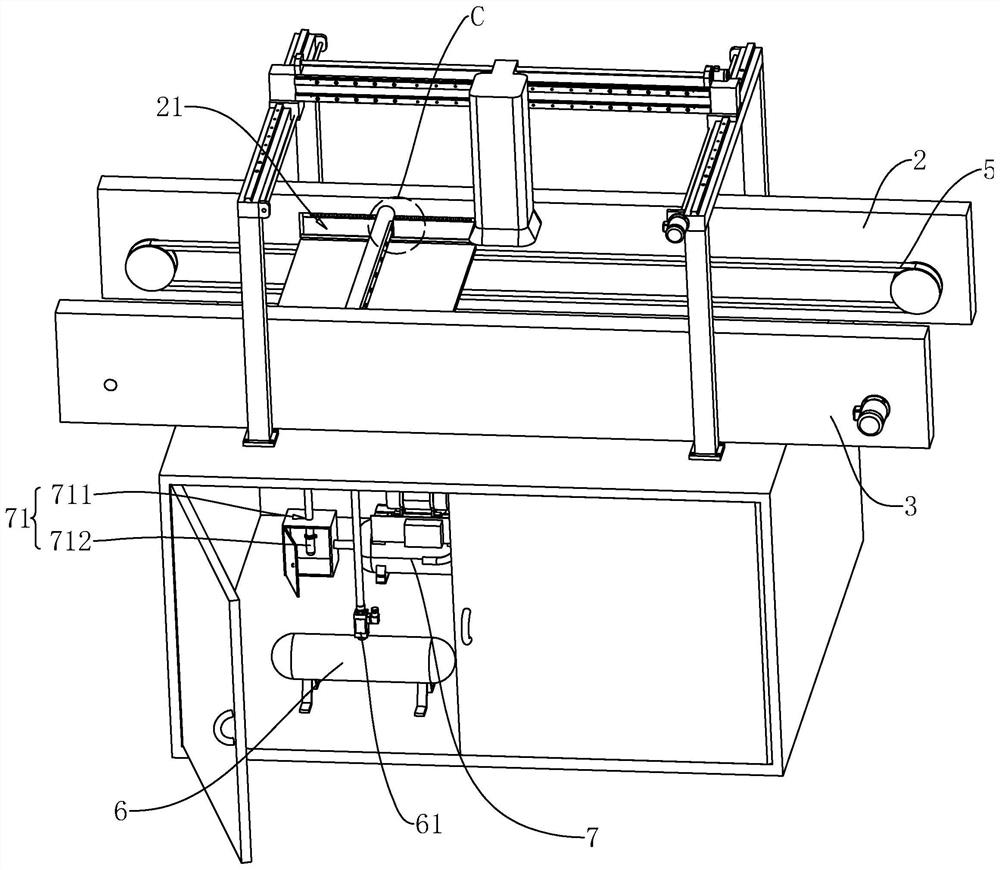

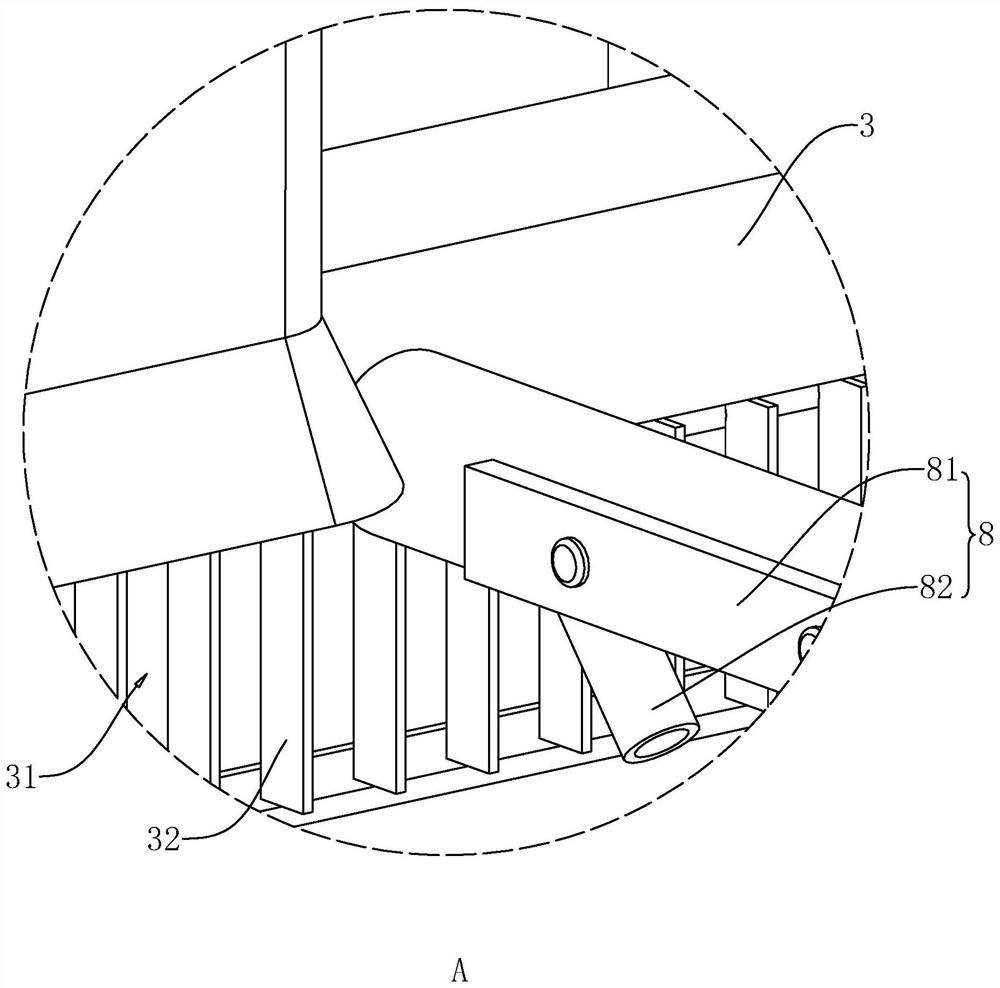

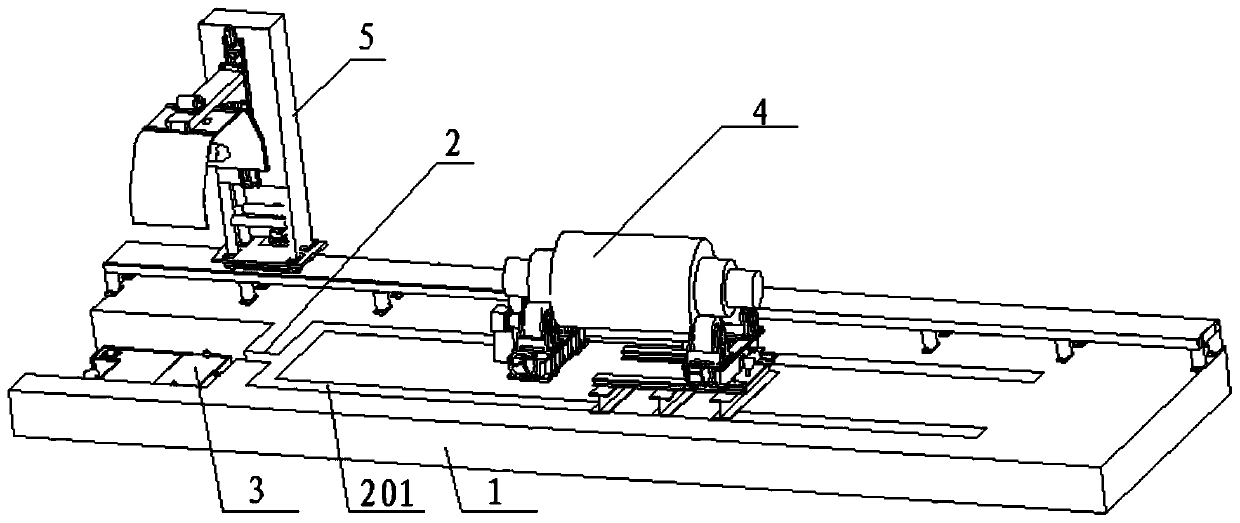

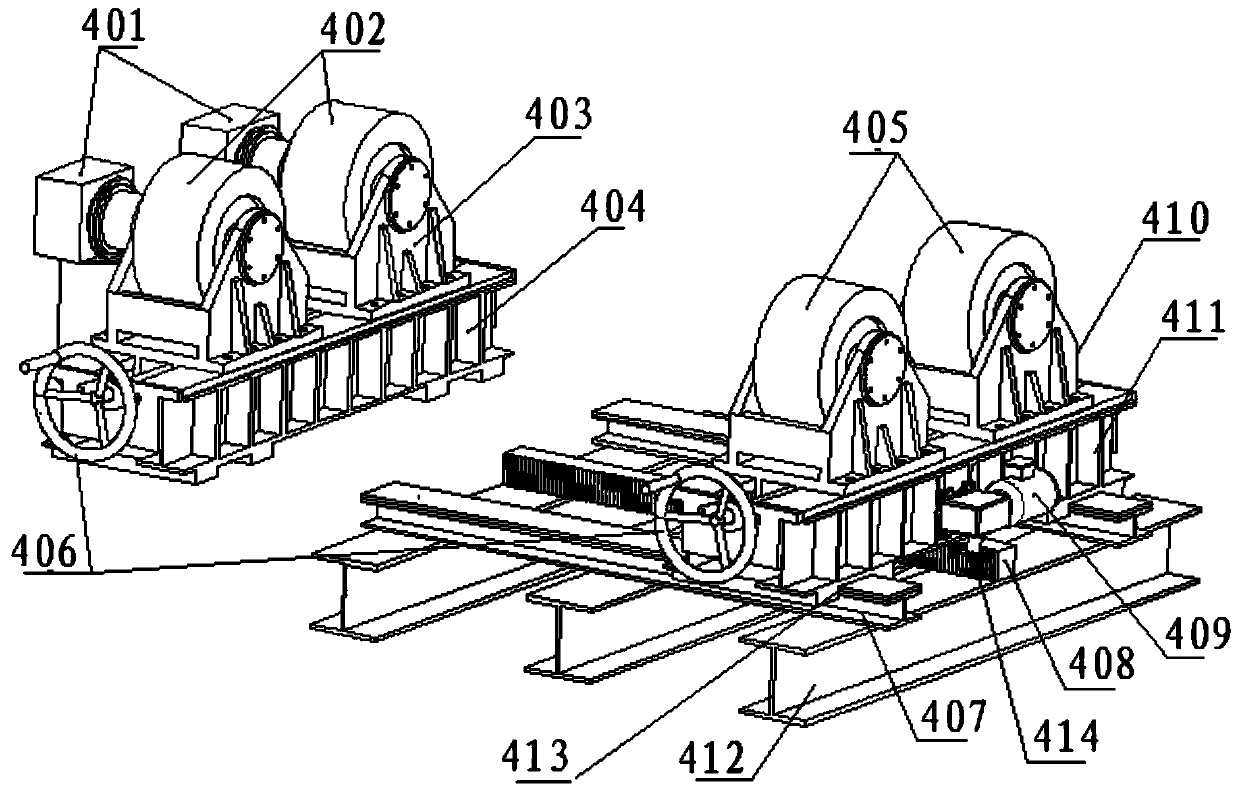

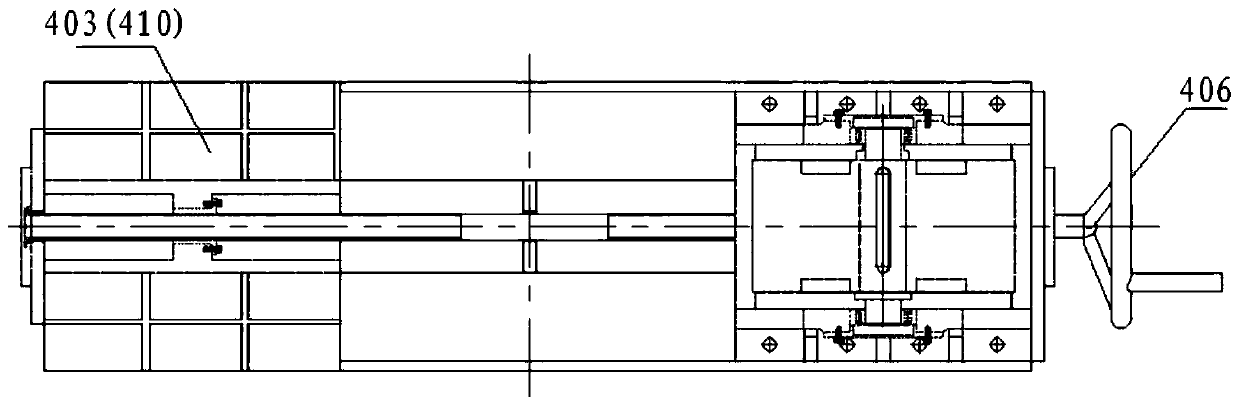

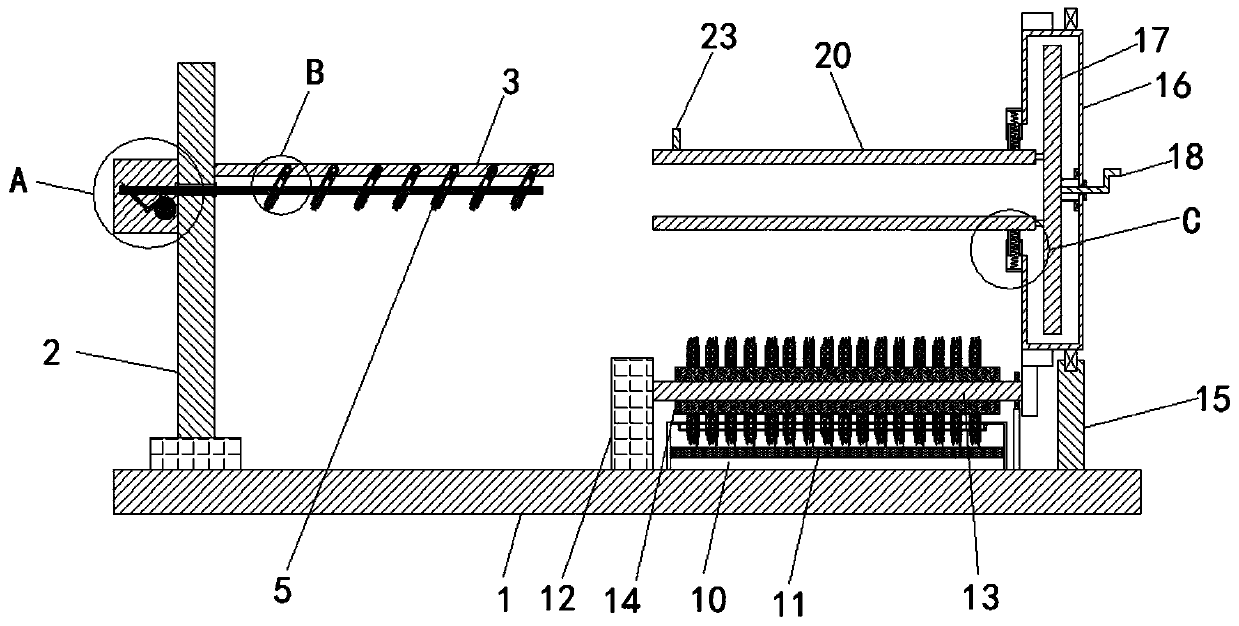

Multi-type roller automatic cleaning equipment

PendingCN110614242AReduce cleaning dead spaceEasy to cleanRolling equipment maintainenceCleaning using toolsEngineeringMechanical engineering

The invention discloses multi-type roller automatic cleaning equipment. The multi-type roller automatic cleaning equipment comprises a base and a recovery flow channel formed in the base. The recoveryflow channel is provided with two branches. The two branches are gathered in a recovery device. A roller supporting device is arranged on the base. A cleaning device is arranged on the base. According to the multi-type roller automatic cleaning equipment, the roller supporting device is arranged on the base and can support different diameters and lengths of rollers according to changes of the positions of rolling wheels at the two ends of a roller, and the multi-type roller automatic cleaning equipment can enable the roller to automatically rotate through a second motor reducer; a nylon rollbrush can do transverse and longitudinal motion through the cleaning device to adapt to different diameters of rollers and move in the length direction of the roller to conduct comprehensive cleaning;the multi-type roller automatic cleaning equipment can drive a cleaning part of the nylon roll brush to rotate through an asynchronous motor to further reduce cleaning dead angles; and the multi-typeroller automatic cleaning equipment enable cleaning fluid to flow downwards onto the base through a shielding device and flow into the recovery device through the recovery flow channel, completes cleaning on the roller and improves the cleaning effect.

Owner:HEBEI INST OF MACHINERY ELECTRICITY

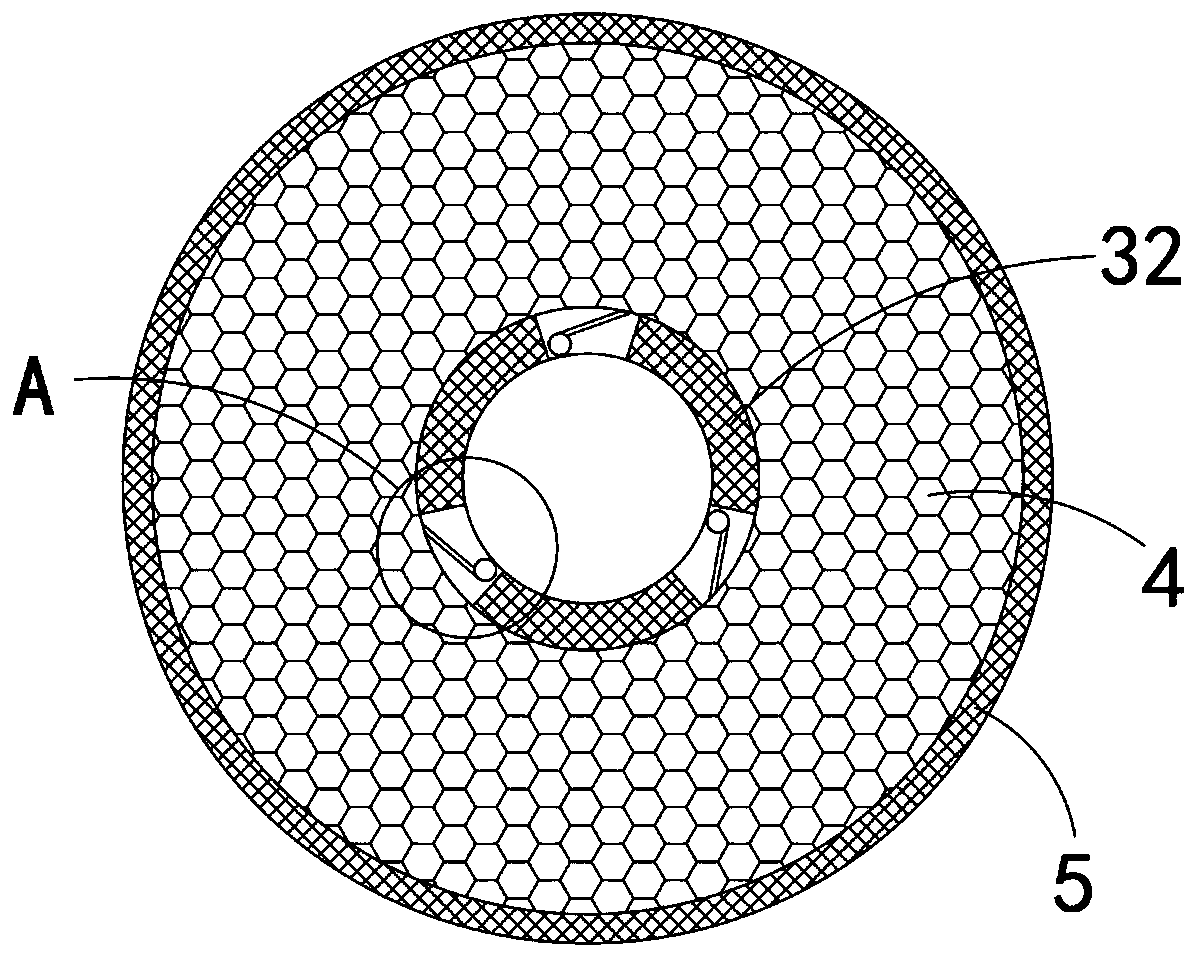

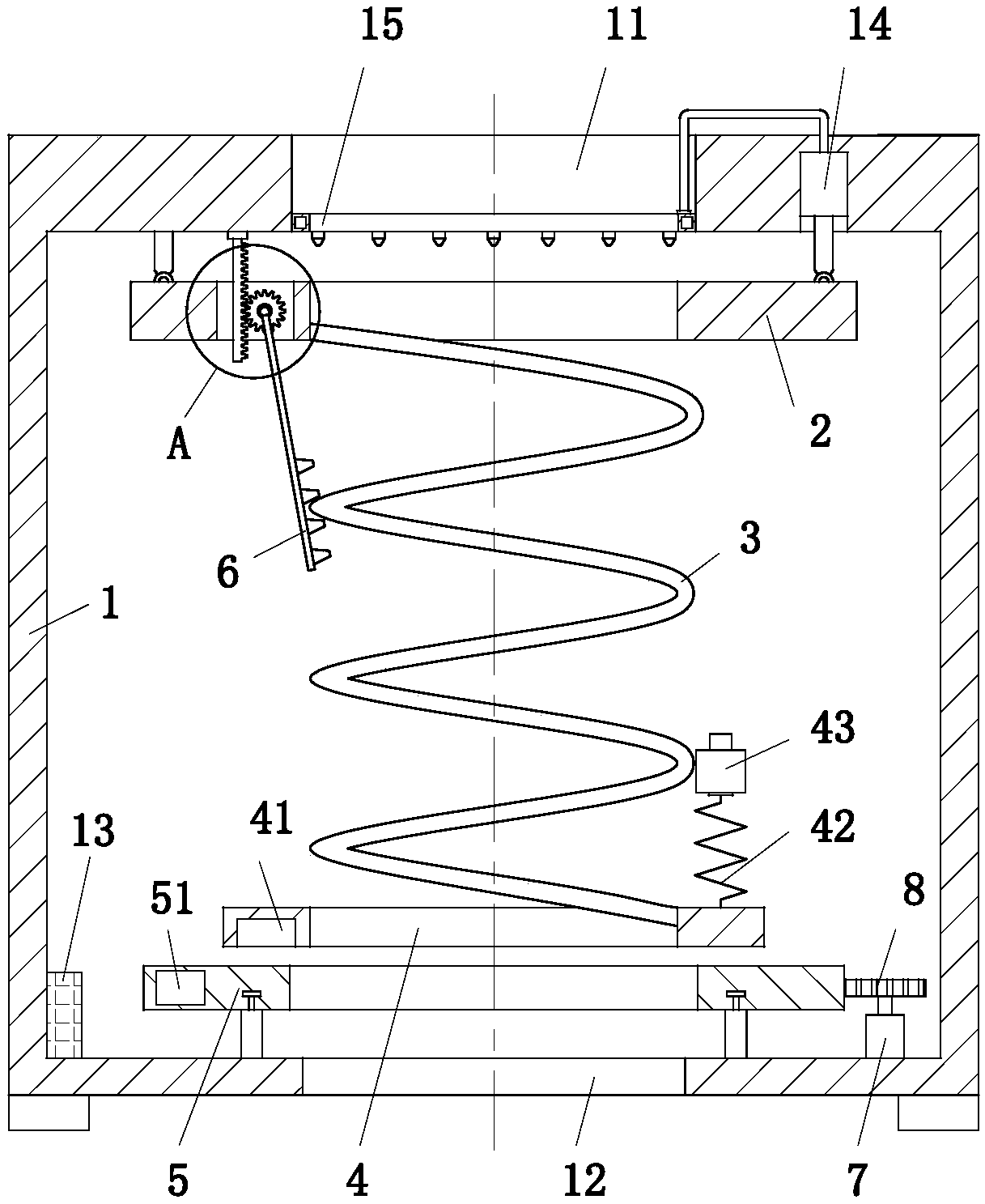

Wire material surface cleaning device

ActiveCN109500104AReduce cleaning dead spaceImprove cleaning efficiencyWork cleaning devicesMetal rolling arrangementsEngineeringWire rod

The invention belongs to the technical field of wire material cleaning equipment and particularly provides a wire material surface cleaning device. The wire material surface cleaning device comprisesa machine body, a cleaning spring, a material inlet and a material outlet, wherein the top of the machine body is provided with the material inlet, the bottom of the machine body is further provided with the material outlet, the position, at the bottom of the machine body, located above the material outlet is provided with an annular toothed disc, the cleaning spring is arranged inside the machinebody, the top end of the cleaning spring is fixedly connected with the inner wall of an annular connection rack, the bottom end of the cleaning spring is fixedly connected with the inner wall of an annular hanging rack, the inner side of an upper spring ring of the cleaning spring is provided with a spiral cleaning hairbrush, the annular hanging rack is arranged above the annular toothed disc, and one end of a wire material penetrates through the material inlet, the annular connection rack, the cleaning spring, the annular hanging rack, the annular toothed disc and the material outlet in sequence. By means of the wire material surface cleaning device, comprehensive cleaning can be performed on the surface of the wire material, the cleaning dead angle is effectively reduced, dust falling of cleaning is speeded up, and improvement of the wire material cleaning quality is facilitated.

Owner:海盐兴欣新材料科技有限公司

Device for removing wool defects on surface of textile fabric

InactiveCN107555229AImprove the surface quality of sampling inspectionReduce cleaning dead spaceFibre treatmentArticle deliveryEngineeringHigh pressure

The invention relates to the field of textiles, and in particular to a device for removing blemishes on the surface of textiles. The device for removing lint on the surface of textiles can completely remove the thread ends and fluff on the surface of the fabrics, and at the same time, it can also remove stains such as oil stains contaminated by the fabrics. . Its structure includes a chassis; a reel is fixed on the upper surface of the chassis through a first bracket; one side of the reel is provided with a box body, and the box body is a cuboid structure; one side of the box body is provided with an electric reel , the electric reel is fixed on the upper surface of the chassis through the second bracket; the side walls of the two sides of the box are respectively provided with a feeding port and a discharging port, and the feeding port and the discharging port are rectangular openings; the said The upper surface of the box body is provided with a high-pressure box, and the high-pressure box is a rectangular hollow structure; the high-pressure box is communicated with the nozzle in the box through an output pipe; the textile cloth depilation device is convenient and efficient to use, with low use cost, and is suitable for removing Thread and fluff on the surface of the fabric.

Owner:RUGAO WANLI CHEM IND

Maintenance device for motor accessories

ActiveCN111293837ATo achieve the effect of mutual non-interferenceWon't fall off easilyCleaning using toolsManufacturing stator/rotor bodiesElectric machineryEngineering

The invention relates to the technical field of motors, and discloses a maintenance device for motor accessories. The device comprises a base. The left side of the upper portion of the base is slidably connected with a base column. The right end of the base column is fixedly connected with a fixed rod; a movable rod is movably inserted into the upper part of the base column; an air pipe extendingto the movable rod is rotatably connected with the fixed rod; an adsorption box is arranged on the right side of the upper portion of the base; a driving device is fixedly installed on the upper portion of the base and located on the left side of the adsorption box; a rotating shaft is arranged at the right end of the driving device; and a brush cylinder is arranged on the rotating shaft. According to the maintenance device for motor accessories, a clamping groove is formed in a clamping plate; the clamping groove matches a rotary adjusting disc to fix a stator; the air pipe swings leftwards and rightwards, and the brush cylinder cleans the interior and exterior of the stator; and an adjusting deflector rod is used to eliminate contact dead corners, and therefore the effects that multiplestators do not interfere with one another when maintained, the stators are strongly fixed, the stators are comprehensively cleaned, and no dead corners are left are achieved.

Owner:山东凯欧电机科技有限公司

Medical equipment disinfection device

InactiveCN110918547BReduce manual operationsImprove disinfection efficiencyCleaning using toolsCleaning using liquidsTransfer mechanismMedical device

Owner:贵州中医药大学

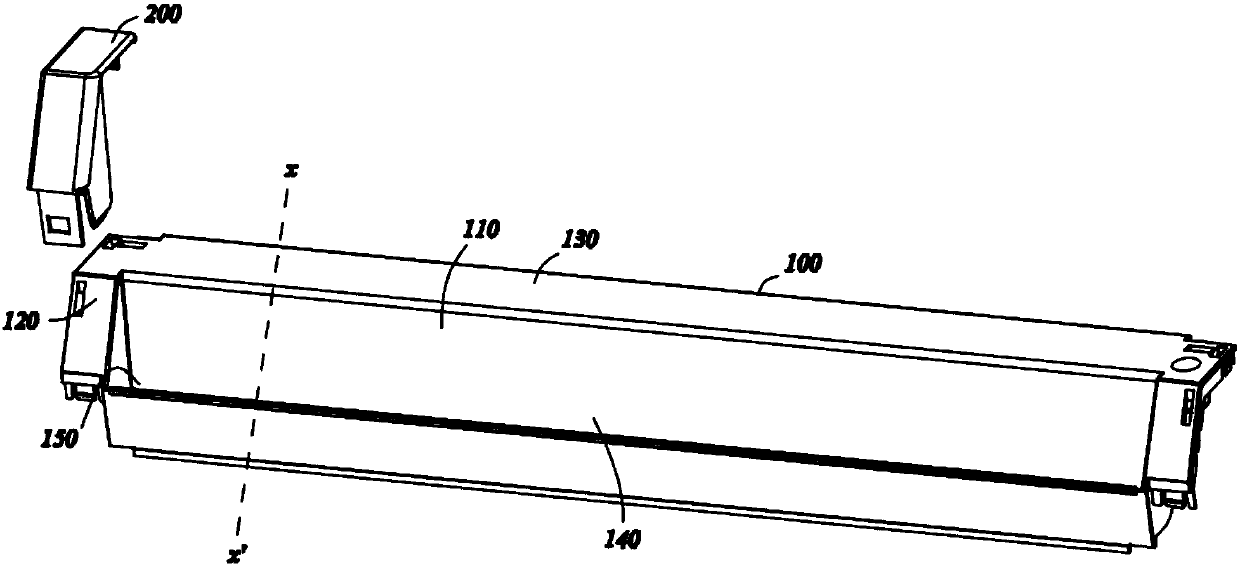

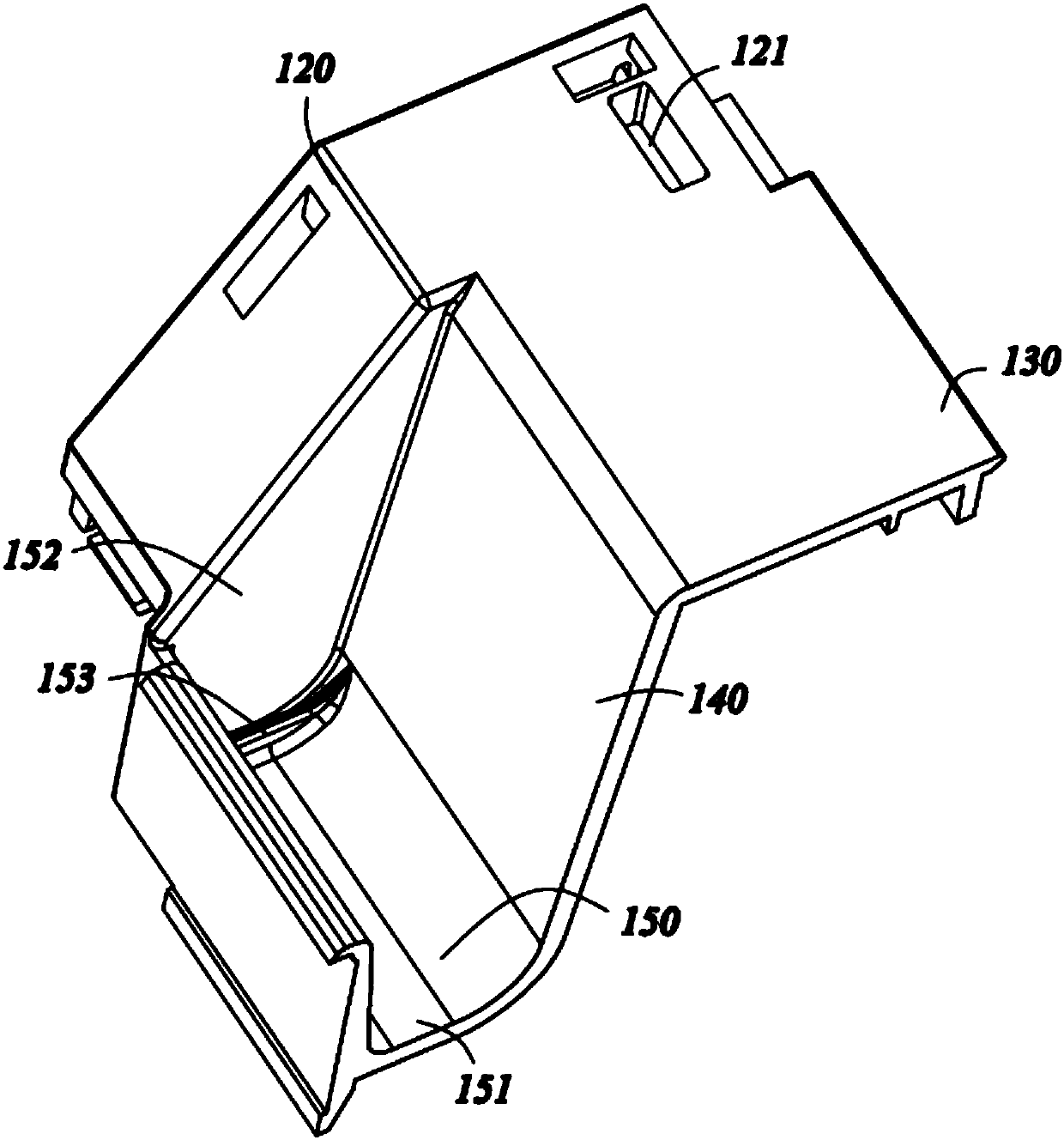

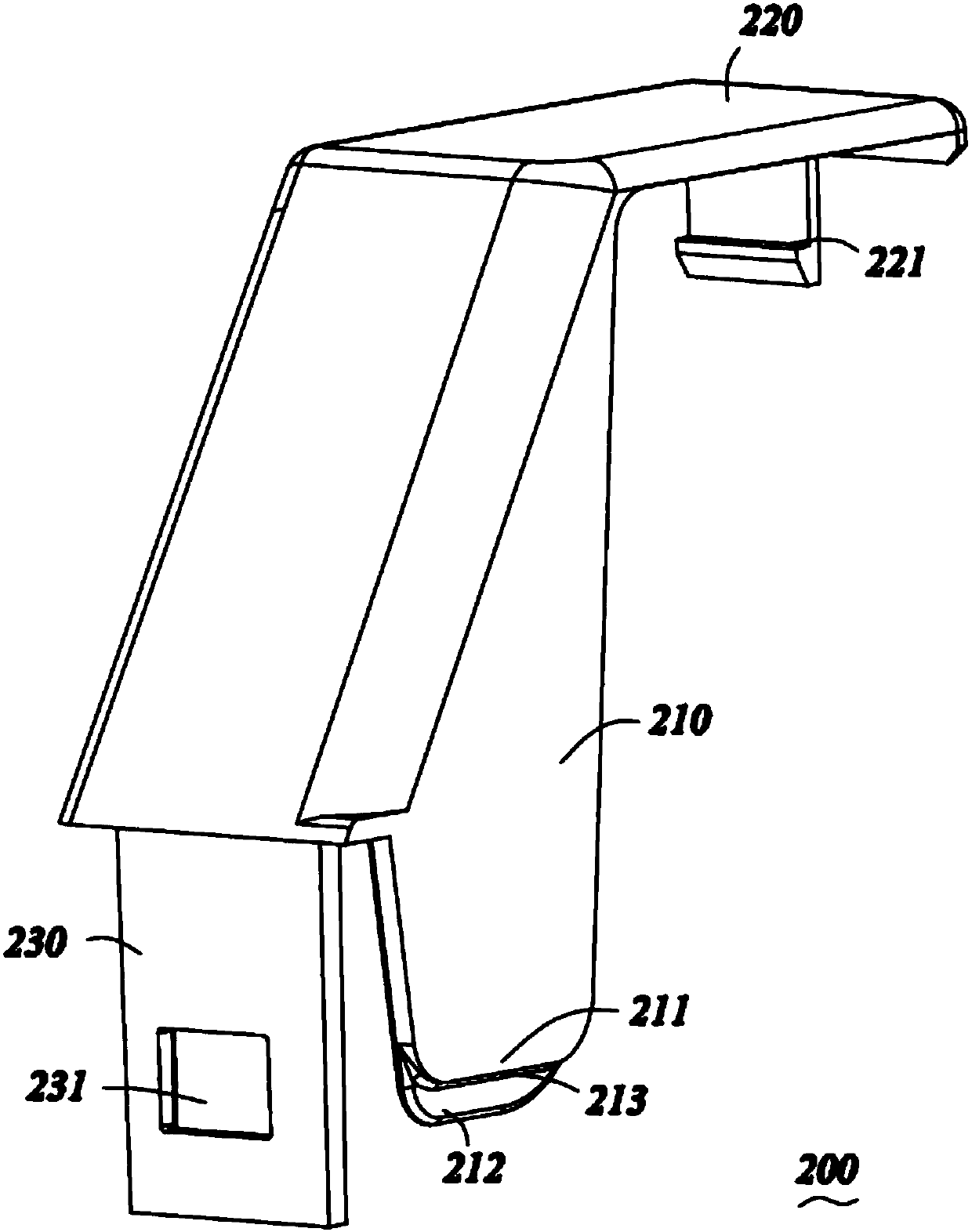

Decorative strip assembly

ActiveCN107588591AStable structureEasy to operateDomestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a decorative strip assembly for a refrigerator door. The decorative strip comprises a top decorative strip assembled on the top of the refrigerator door. The top decorative strip comprises a decorative strip body and installing portions formed at the two ends of the decorative strip body. The decorative strip assembly further comprises a decorative piece which is installedabove the installing portions and at least shields part of the installing portions. The decorative strip assembly is simple and firm in structure and easy to operate, the practicability is improved while the attractiveness is improved, the number of cleaning dead angles is reduced, and scrubbing is more conveniently performed.

Owner:CHONGQING HAIER REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

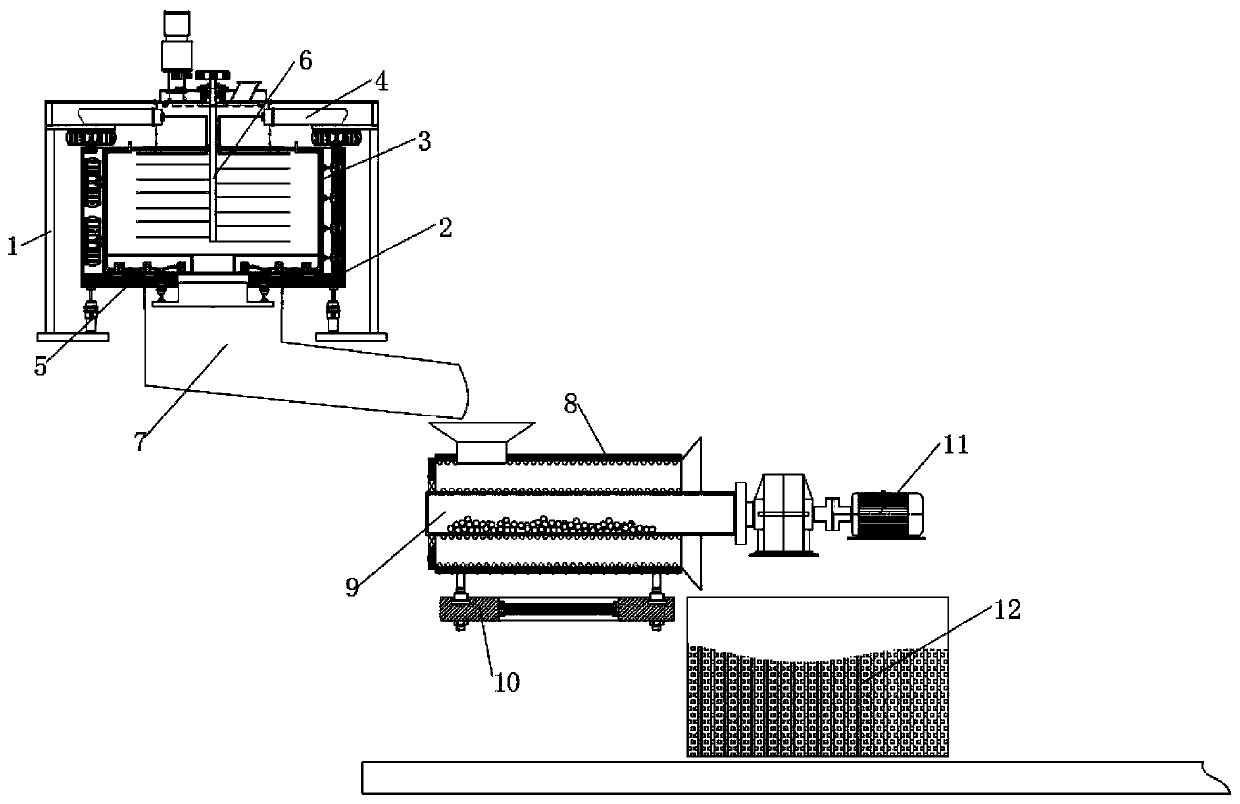

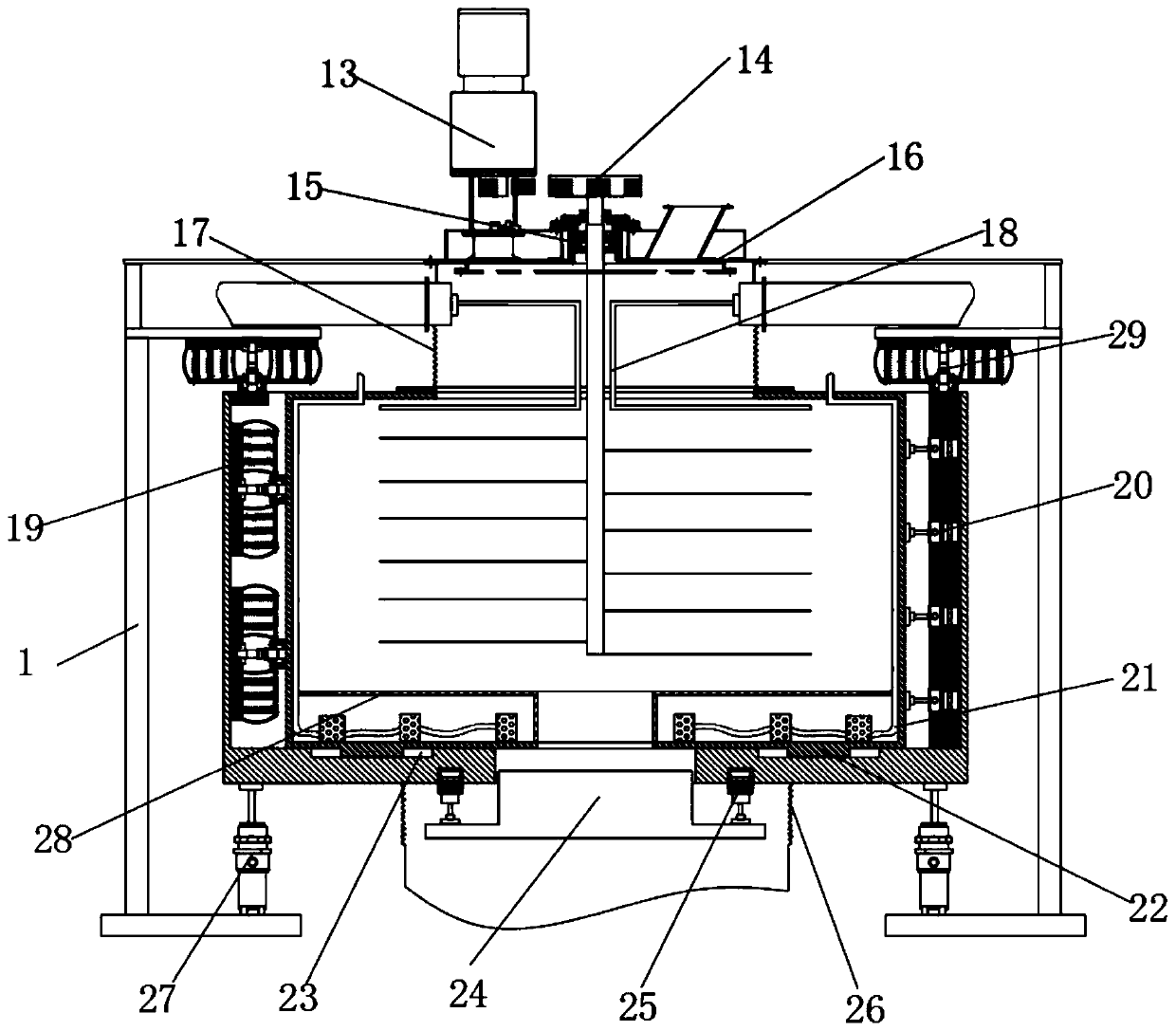

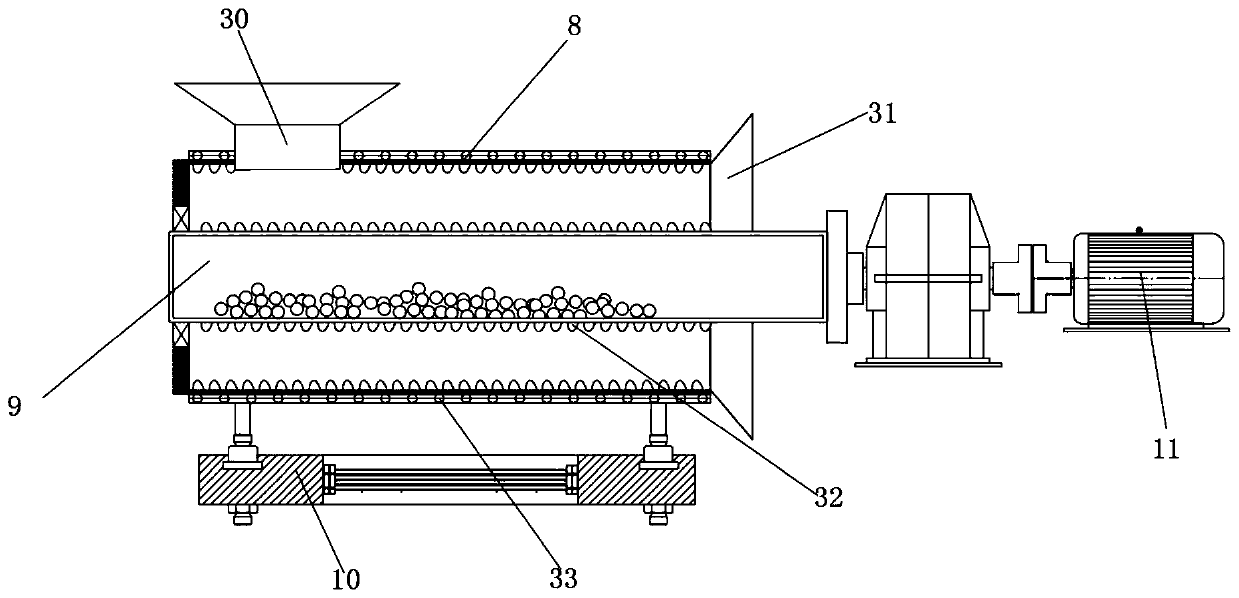

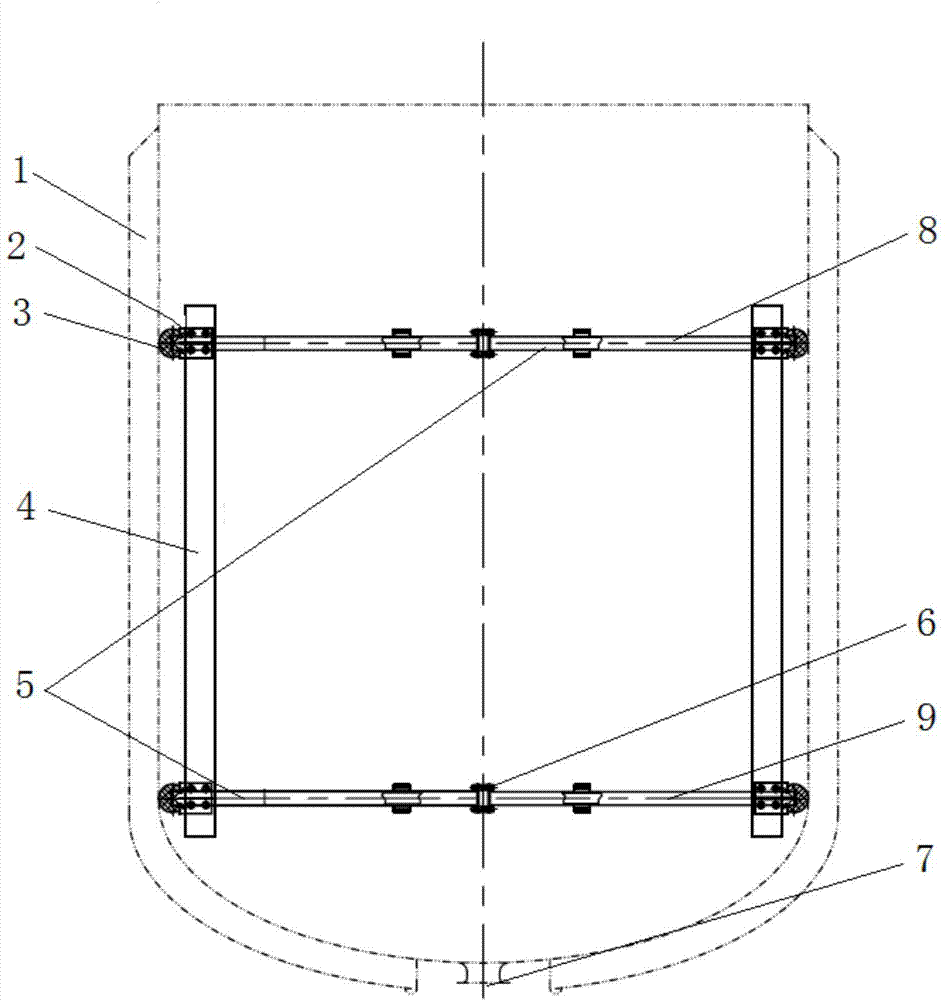

Fungus cleaning equipment used for fungus milk processing

ActiveCN110679973AImprove qualityWash thoroughlyClimate change adaptationGrain treatmentsBiotechnologyMicrobiology

The invention discloses fungus cleaning equipment used for fungus milk processing. The fungus cleaning equipment comprises a rack, a vertical oscillation component, a lateral oscillation component, astirring component, a cleaning component, a pollution discharge component and a primary grinding and drying component, wherein the vertical oscillation component is arranged on the rack for verticallyoscillating an outer shell seat; the lateral oscillation component is arranged in the outer shell seat for laterally oscillating an inner shell seat; and the input end of the stirring component extends into the inner shell seat to be cooperated with the cleaning component and the pollution discharge component to realize the cleaning of fungi. The fungus cleaning equipment is provided with the vertical oscillation component and the lateral oscillation component, so that the outer shell seat can vertically oscillate and the inner shell seat can oscillate between left and right when the fungi are cleaned; and meanwhile, the fungi can be fully stirred and cleaned through stirring blades, and therefore, the fungi in the equipment can be more thoroughly cleaned. The device is provided with theprimary grinding and drying component, and the fungi which are just cleaned can be subjected to preliminary grinding and drying processing so as to lay a good foundation for postprocessing.

Owner:湖北忠厚乳业集团有限公司

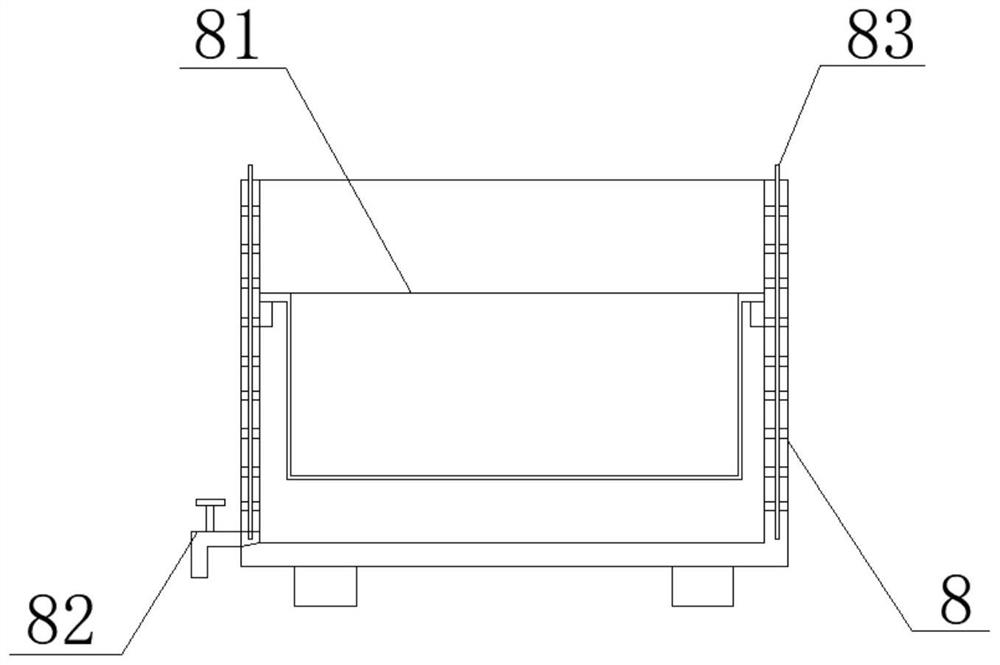

Water washing equipment for terpene resin

InactiveCN104772302APrevent "vortex" phenomenonWell mixedCleaning using liquidsArchitectural engineeringEnamel structure

The invention discloses water washing equipment for terpene resin. The water washing equipment for terpene resin comprises a water washing tank body and a flow blocking device arranged inside the water washing tank body, wherein a stirring device is also arranged inside the water washing tank body, the inner wall of the water washing tank body is of an enamel structure, the flow blocking device comprises two installing steel rings and a flow blocking plate, the two installing steel rings are respectively the upper installing steel ring and the lower installing steel ring which have the same structure, the upper end of the flow blocking plate is fixedly arranged on the upper installing steel ring, the lower end of the flow blocking plate is fixedly arranged at the lower installing steel ring, an elastic positioning sleeve is arranged on the outer part of the circumference of each installing steel ring, and a regulating screw bolt used for regulating the size of the circumference is arranged on each installing steel ring. The water washing equipment has the design purpose of solving the problems of poor anti-corrosion effect, low water washing efficiency and high equipment replacement cost of the existing water washing equipment.

Owner:广东星光脂胶科技股份有限公司

Energy-saving and environmental-friendly device for cleaning arc-shaped filter screen of air conditioner

ActiveCN112254327AEasy to cleanFully contactedDispersed particle filtrationLighting and heating apparatusDrive shaftGear wheel

The invention relates to the technical field of electrical accessories, and discloses an energy-saving and environmental-friendly device for cleaning an arc-shaped filter screen of an air conditioner.The device comprises a rack, wherein a servo motor is fixedly connected to the top end of the interior of the rack, a driving gear is fixedly connected to the top end of the servo motor, a transmission gear is meshed with the outer wall of the driving gear, cleaning rollers are fixedly connected to the outer wall of the transmission gear, universal transmission shafts are fixedly connected to theouter walls of the cleaning rollers, a supporting plate is fixedly connected to the outer wall of the rack, and a water supply pipe is fixedly connected to the inner wall of the supporting plate. According to the energy-saving and environmental-friendly device for cleaning the arc-shaped filter screen of the air conditioner, the cleaning rollers are extruded in the direction of the filter screento be cleaned, so that the cleaning rollers which are in contact with the filter screen firstly extrude telescopic rods downwards, the telescopic rods overcome the elastic force of buffer springs to move downwards, the cleaning rollers on the two sides can be in full contact with the surface of the filter screen, the cleaning dead angle is reduced, and the cleaning effect of the filter screen is improved.

Owner:YANCHENG SHENHAI MASCH CO LTD

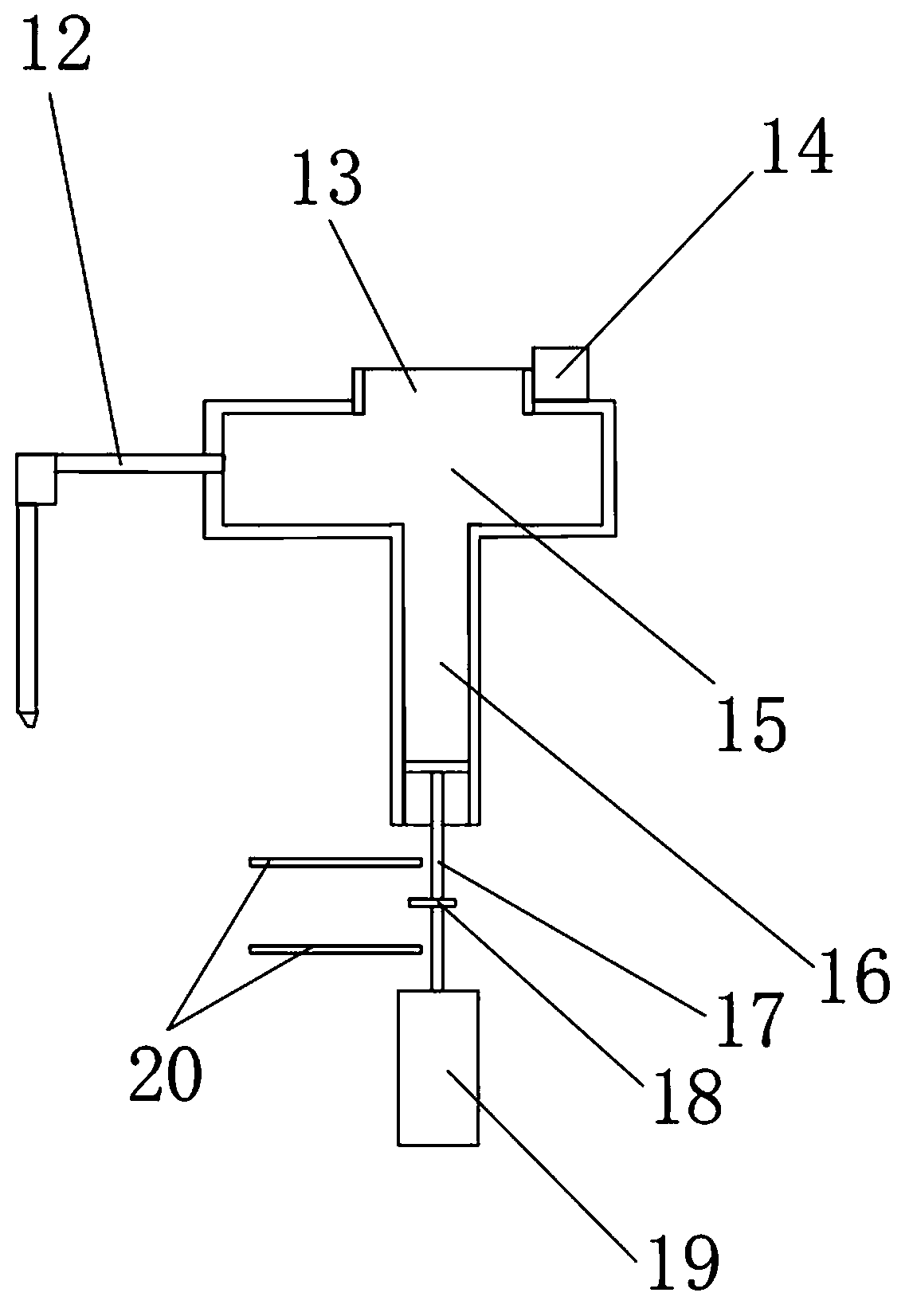

Vertical pneumatic filling device and using method thereof

PendingCN108216710ALoss or affect qualityAffect qualityLiquid materialFilling materialsComputer module

The invention provides a vertical pneumatic filling device and a using method thereof. The filling mechanism of the filling device comprises a control module, a temporary storage cavity, a suction mechanism and an extrusion mechanism, wherein an input port of the filling mechanism is arranged at the cavity wall of the temporary storage cavity and is provided with a check valve; the suction mechanism is connected to the temporary storage cavity through a suction cylinder; and when filling operation is carried out, the check valve communicates with the input port of the filling mechanism, the suction mechanism drives the suction cylinder to suck to-be-filled materials with the preset temporary storage amount into the temporary storage cavity, then the check valve closes the input port of thefilling mechanism, the suction mechanism reversely drives the suction cylinder to apply pressure to the to-be-filled materials in the temporary storage cavity, and an extruding mechanism is used forextracting the materials in the temporary storage cavity according to the preset filling amount and guiding the materials into an external packaging container. According to the vertical pneumatic filling device and the using method thereof, the high-viscosity high-value materials can be conveniently subjected to small-batch filling, the attractiveness and the packaging amount of finished productsare further not prone to be influenced due to bubbles, and the device can be conveniently cleaned and maintained.

Owner:福州法莫优科机械科技有限公司

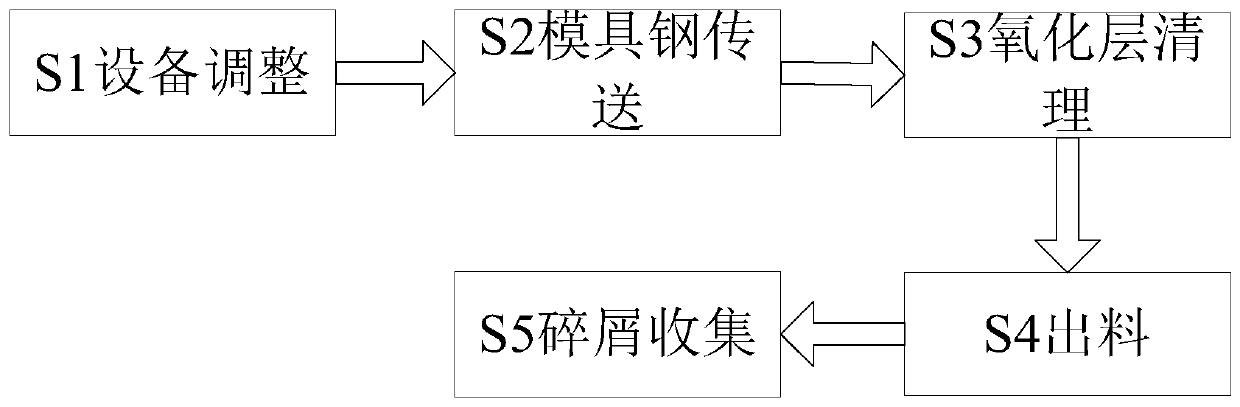

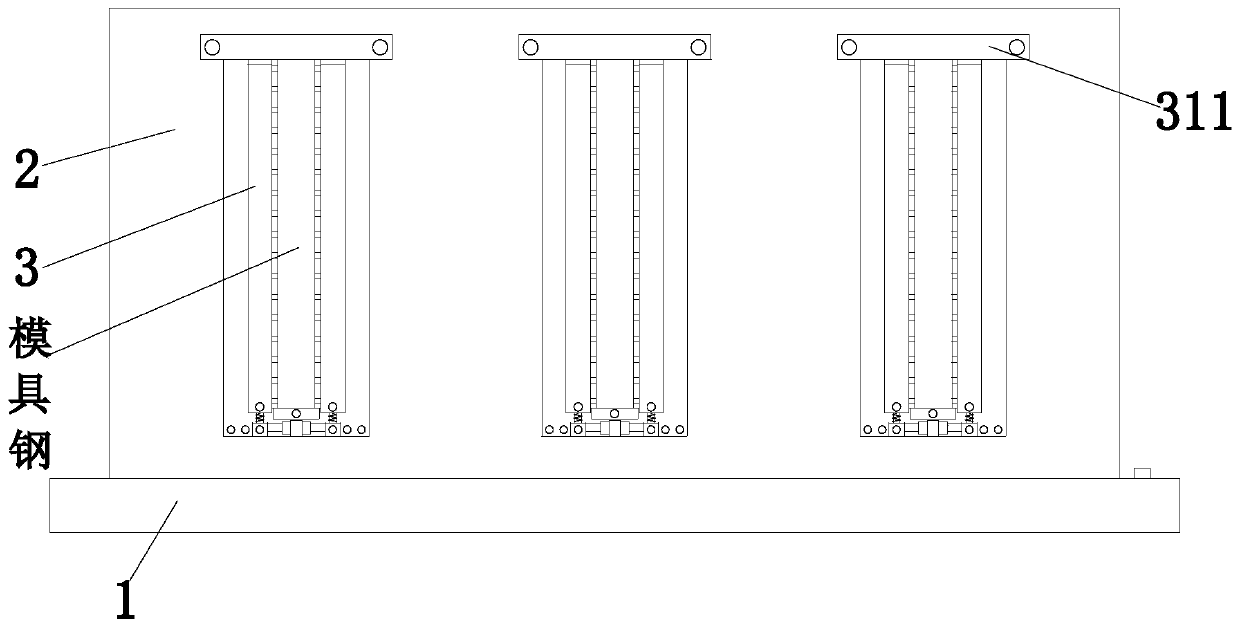

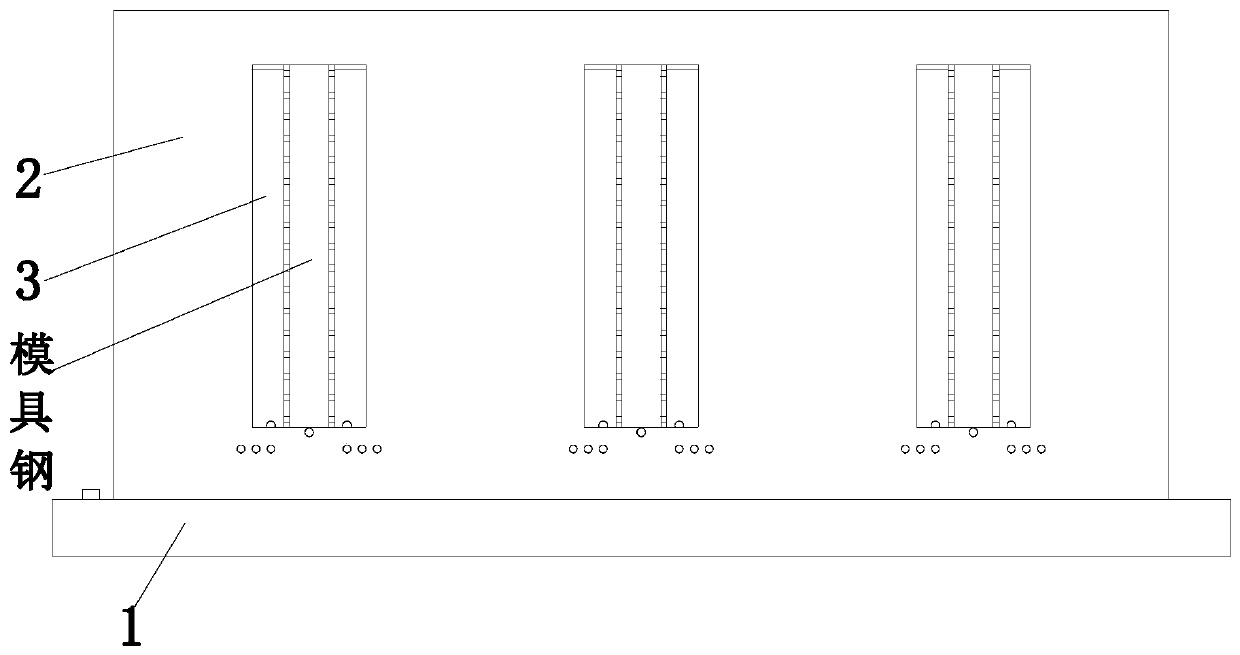

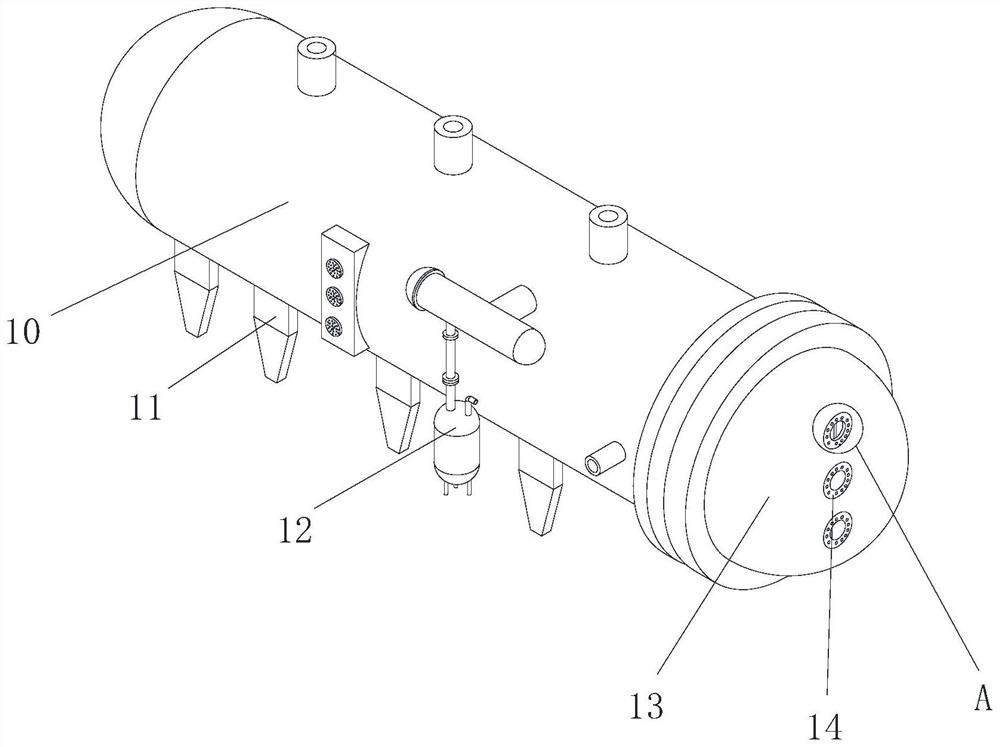

Surface treatment method of die steel after molding

ActiveCN111571398AEasy to replaceExpand the scope of cleaningGrinding drivesGrinding machinesElectric machineryStructural engineering

The invention relates to a surface treatment method of die steel after molding. Oxide layer cleaning equipment is used and comprises a base plate, a shell and a cleaning device. The specific technological process for cleaning oxide skins on the surface of the die steel by adopting the oxide layer cleaning equipment comprises the following steps of equipment adjustment, die steel transferring, oxide layer cleaning, discharging and fragment collecting. The cleaning device comprises cleaning branch chains, connecting blocks, moving frames, telescopic rods, rotating cams, rotating rods and rotating motors, and the cleaning branch chains comprise top plates, extrusion blocks, cleaning brushes, linkage plates and inserting frames. According to the surface treatment method of the die steel aftermolding, the cleaning brushes can be driven to move back and forth in multiple directions during cleaning, so that the purposes of expanding cleaning ranges and reducing cleaning dead angles are achieved, the cleaning brushes are of detachable combination structures, and the cleaning brushes with long-time use are convenient to clean and parts are convenient replace.

Owner:浙江利源重工科技有限公司

Low-temperature drying system without destroying effective components of collagen peptide powder

ActiveCN114279176AImprove permeabilityEasy to observe working conditionsDrying solid materials without heatChemical industryThermodynamicsEngineering

The invention relates to the technical field of collagen peptide drying systems, and discloses a low-temperature drying system without damaging effective components of collagen peptide powder, a cleaning mechanism is arranged on the surface of observation glass, and the cleaning mechanism comprises a scraping plate, an air hole I, a fixing ring, an inner sliding groove, a partition plate, an air hole II, an ejector rod, a sliding block, a strong magnetic block, an outer sliding groove and a metal block; external air enters the inner sliding groove from the first air hole and reaches the opposite side of the second air hole, due to the fact that the air in the inner sliding groove is exhausted from the second air hole, the external air entering the inner sliding groove is located between the partition plate and the sliding block, and the external air pushes the sliding block to slide in the inner sliding groove. The strong magnetic block attracts the metal block to synchronously slide in the outer sliding groove and do circular motion, the metal block drives the scraping plate to do circular motion on the left side of the observation glass and scrape the wall face, located in the drying tank, of the observation glass, the permeability of the observation glass is improved, and the working condition in the drying tank can be conveniently observed.

Owner:温州金榜轻工机械有限公司

Classification and recovery device for garbage generated by cell culture

ActiveCN114476434AReduce work intensityPrevent reboundWaste collection and transferRefuse receptaclesProcess engineeringGarbage collection

The invention provides a classifying and recycling device for garbage generated by cell culture, and relates to the technical field of garbage recycling, the classifying and recycling device comprises a classifying device, a receiving funnel, a storage device and a supporting device, the receiving funnel is installed at the top of the classifying device, and the bottom of the classifying device is connected to the interior of the storage device; the supporting device is installed at the bottom of the storage device, and the classification device comprises a shell, a center supporting column, a limiting panel and a separation spiral plate. According to the invention, the receiving funnel and the separation spiral plate are combined for use to receive the garbage generated by cell culture, and the traditional mode that a waste plastic box is directly used as a garbage recovery container is changed, so that the garbage can be used for a long time; and the dry garbage and the wet garbage can be automatically and separately transported and stored when the garbage is combined with the hollow rectangular pipe, so that the problem that bacteria are easily generated when different types of garbage are mixed together is avoided.

Owner:张霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com