Homogeneous emulsification and filling integration device and application method thereof

A homogeneous emulsification and filling technology, applied in chemical instruments and methods, mixing methods, mixers with rotating stirring devices, etc., can solve the difficulties of feeding, discharging and packaging, generation of air bubbles, inaccurate packaging volume, etc. problem, achieve the effect of reducing cleaning dead angle, facilitating cleaning, and promoting emulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

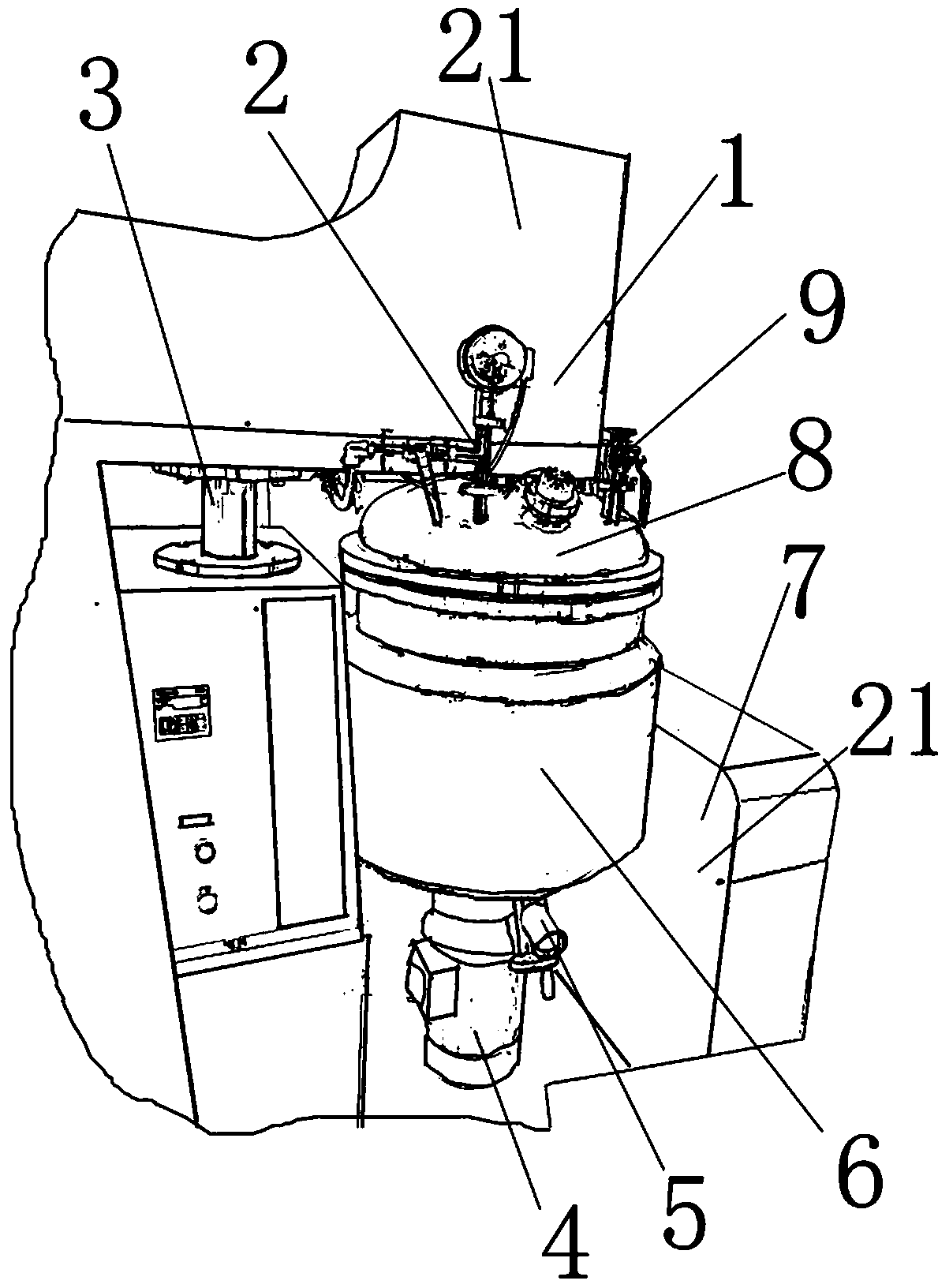

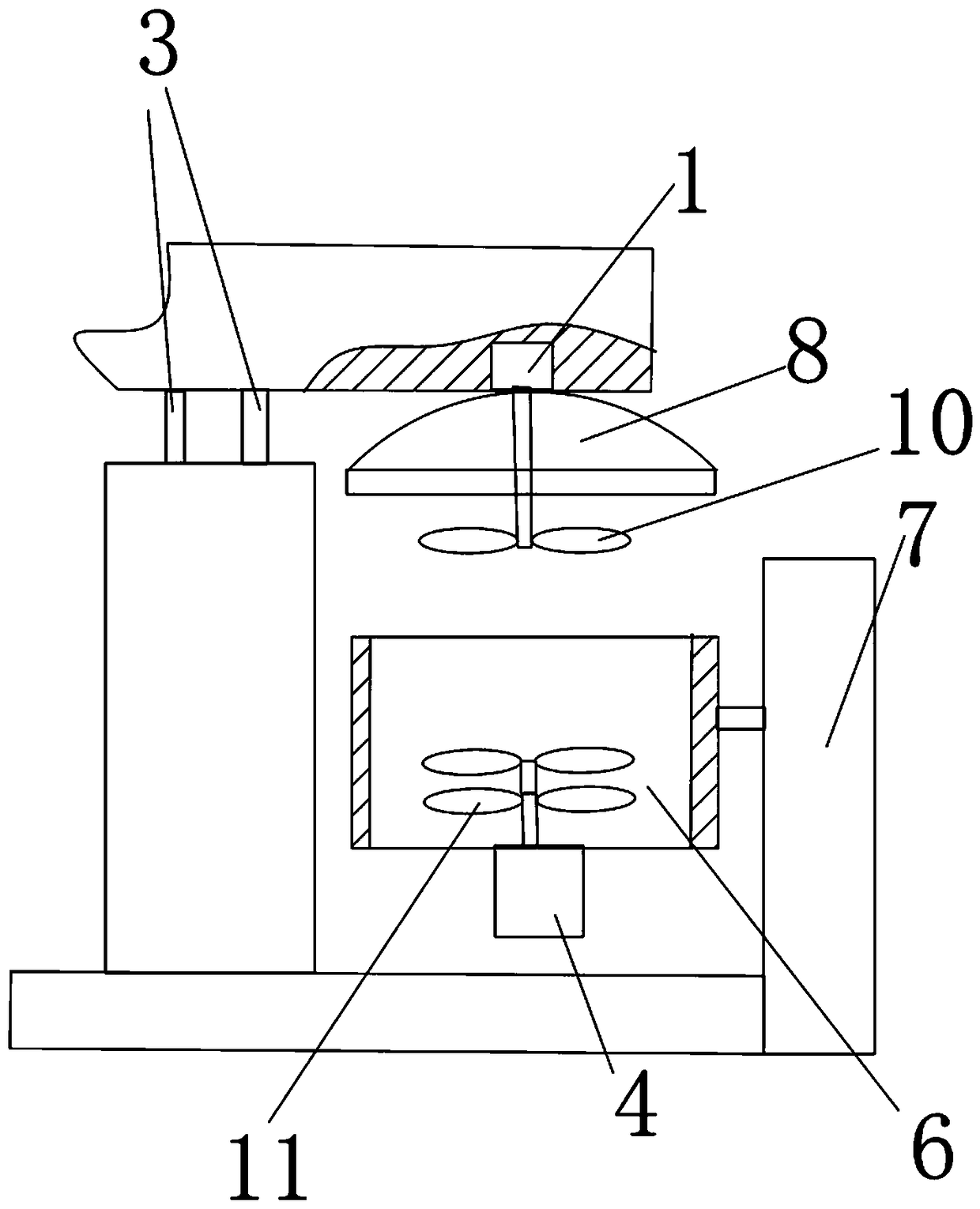

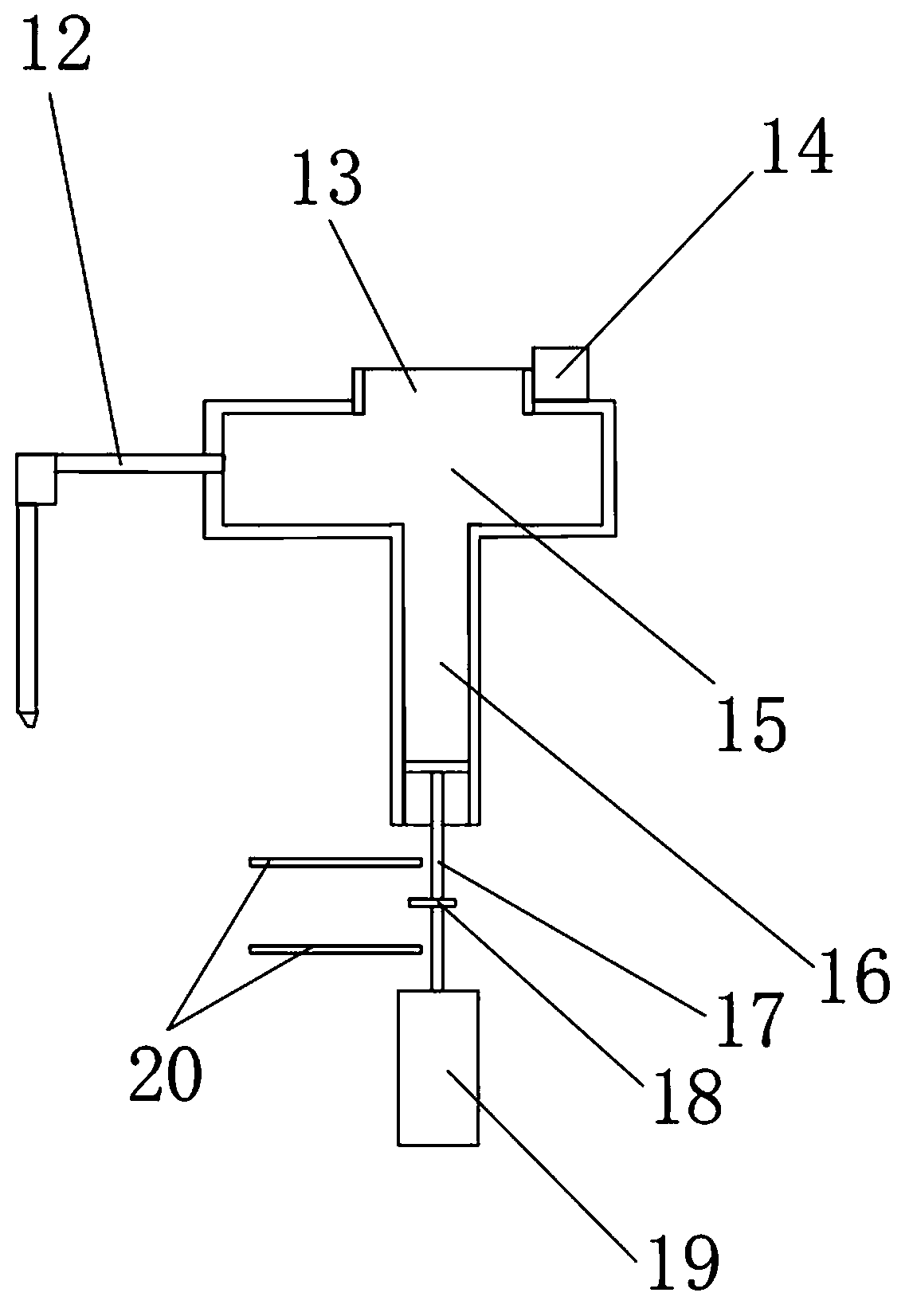

[0032] Such as Figure 1-3 As shown, the homogeneous emulsification and filling integrated device can perform homogeneous emulsification and filling operations on high-viscosity materials. The integrated device includes a homogeneous emulsification mechanism; the homogeneous emulsification mechanism includes a control module, a vacuum tank 6 and a machine platform 21, the vacuum tank loam cake 8 places are connected with an air pump 2 and a first motor 1, and the bottom of the vacuum tank tank is provided with a discharge port 5 and a second motor 4 integrated with the vacuum tank; The first motor 1 and the second motor 4 are respectively connected to the stirring mechanism in the vacuum tank 6; The side walls of 6 are connected; when the vacuum tank 6 is sealed and the air pump 2 is pumped to form a negative pressure, the external air pressure will press the material into the tank 6 through the suction port 9 of the vacuum tank; when the mouth of the vacuum tank needs to be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com