Steel connection structure and its connection method

A connection structure and connection method technology, applied in the direction of building structure and construction, can solve the problems of difficulty in maintaining horizontal beams and inconvenience, and achieve the effect of compact structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

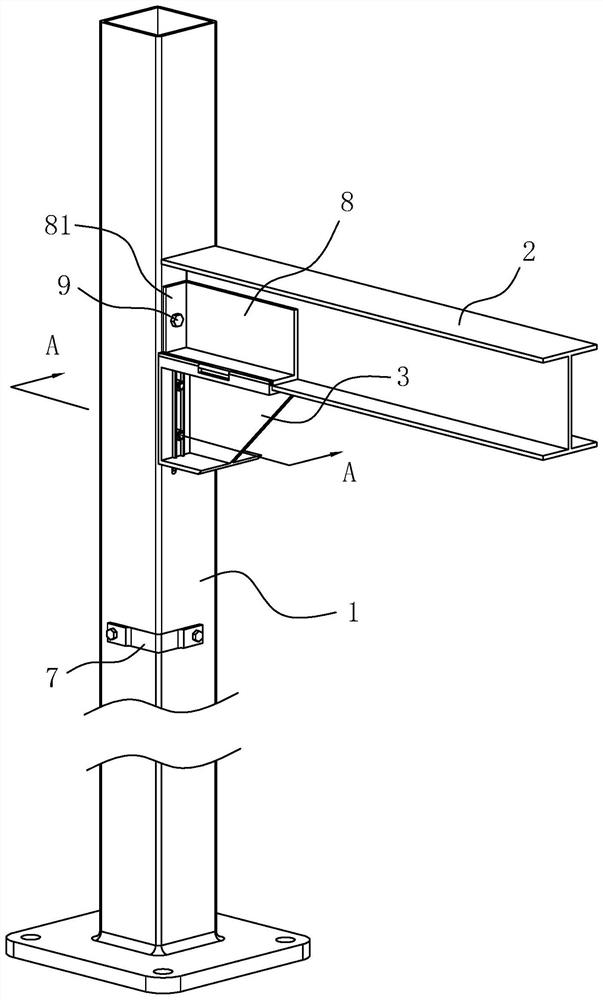

[0043] refer to figure 1 , is a steel connection structure disclosed in the present invention, comprising a pillar 1 and a beam 2, and the pillar 1 is provided with a support 3 for supporting the end of the crossbeam 2; after the installation of the steel connection structure is completed, the pillar 1 passes through the bottom Fixed on the ground, the length direction of the pillar 1 is along the vertical direction, and the length direction of the beam 2 is along the horizontal direction.

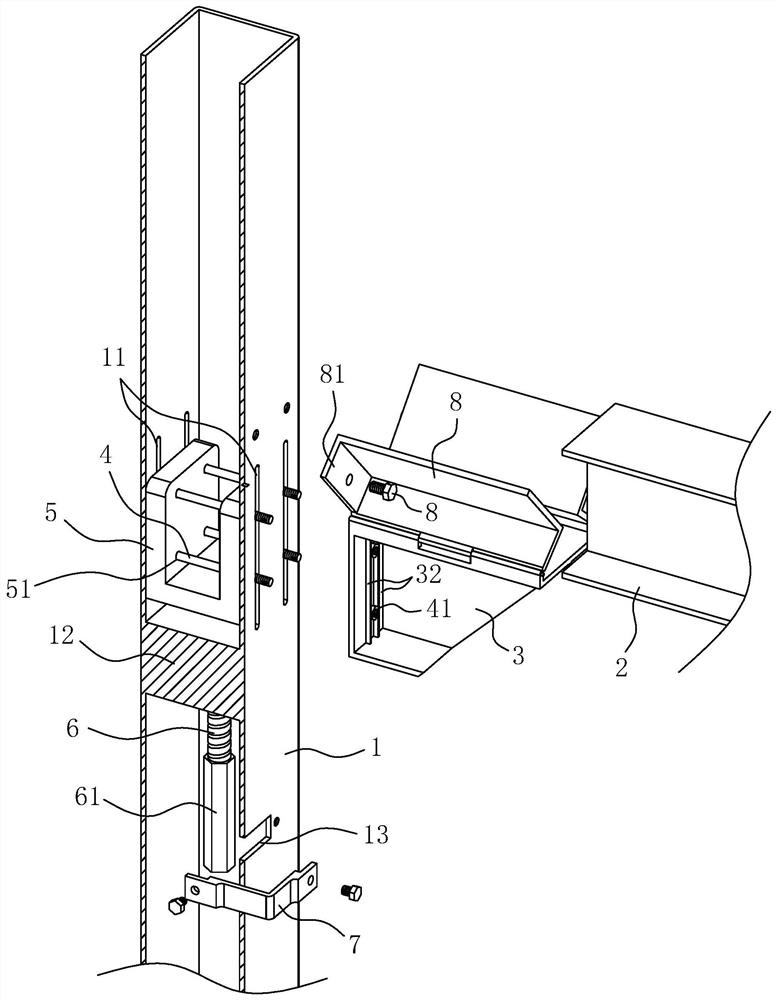

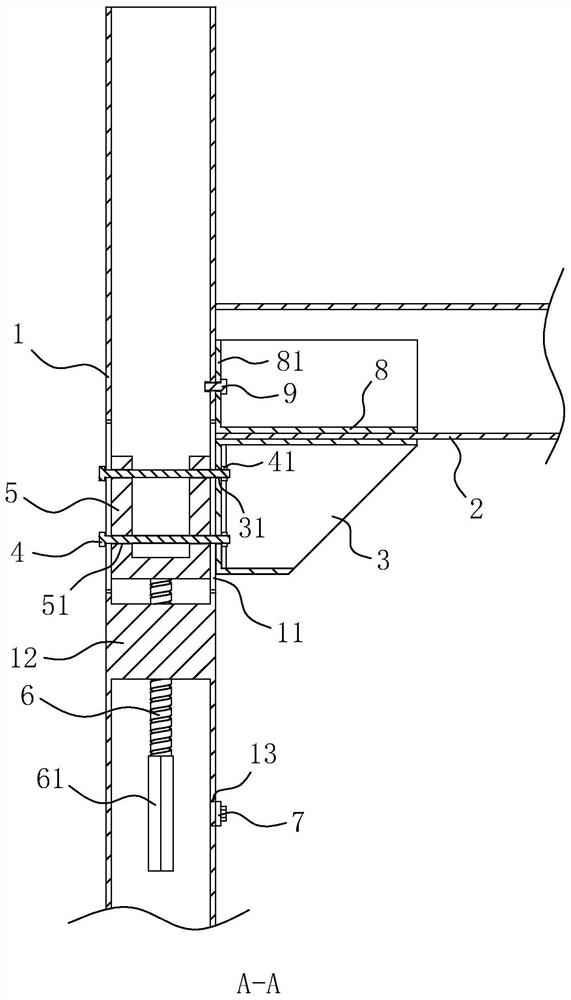

[0044] refer to figure 2 with image 3 , the cross section of the pillar 1 is rectangular, and the interior of the pillar 1 is hollow. The support 3 and the pillar 1 establish a sliding connection through the bolt one 4 passing between the two. Two bolts 4 are arranged along the length direction of the pillar 1 to form a pair, and the bolt one 4 is arranged on the pillar 1 along the horizontal direction. two pairs. The support 3 is provided with a hole for the bolt 1 to pass through, ...

Embodiment 2

[0050] A connection method for connecting the above-mentioned steel connection structure, comprising the following steps:

[0051] Step 1: Install the pillar 1 on the ground, and ensure that the length direction of the pillar 1 is in the vertical direction during installation.

[0052] Step 2: Place the beam 2 on the support 3, and then wait for more than three hours; during the waiting time, the gravity of the beam 2 acts on the pillar 1 through the support 3. If the ground under the pillar 1 subsides, use Settlement is completed on support pillar 1.

[0053] Step 3: Use a spirit level to check the levelness of the beam 2. If the beam 2 is inclined to the horizontal plane, the personnel loosen the bolt 1 4, remove the sealing plate 7, pass the wrench through the operation hole 13 and turn the hexagonal screw head 61, and adjust the support 3 the height until the beam 2 is parallel to the horizontal plane.

[0054] Step 4: Put back the sealing plate 7, and turn the splint 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com