Preparation method of single-sided hot-melt adhesive waterproof membrane and double-sided hot-melt adhesive waterproof membrane

A waterproof membrane and hot-melt adhesive technology, applied in roofing, adhesives, roof coverings, etc., can solve the problems of poor durability and low temperature resistance, low viscosity, high raw material cost, etc., achieve excellent impact resistance, reduce production costs, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

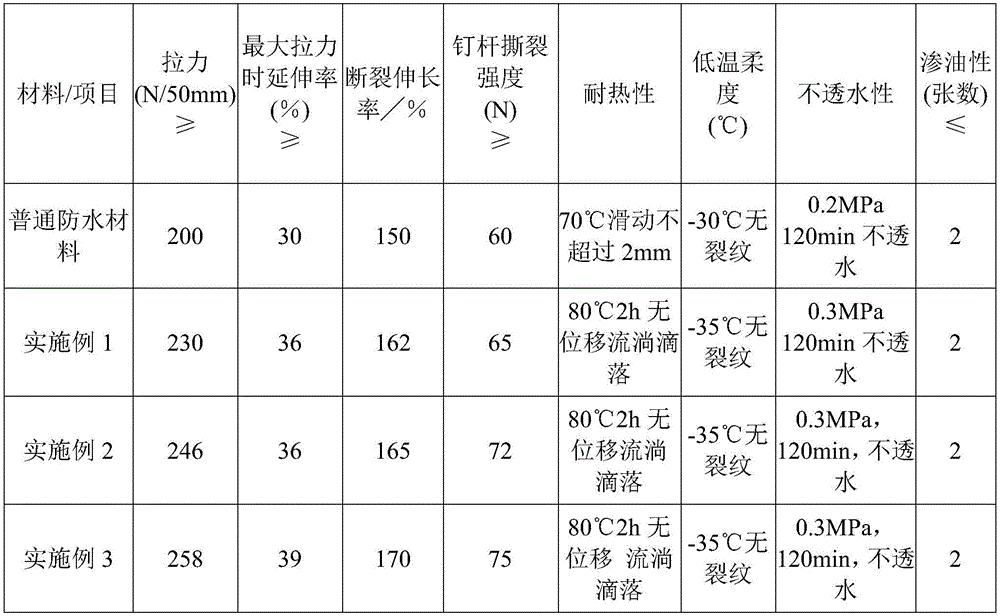

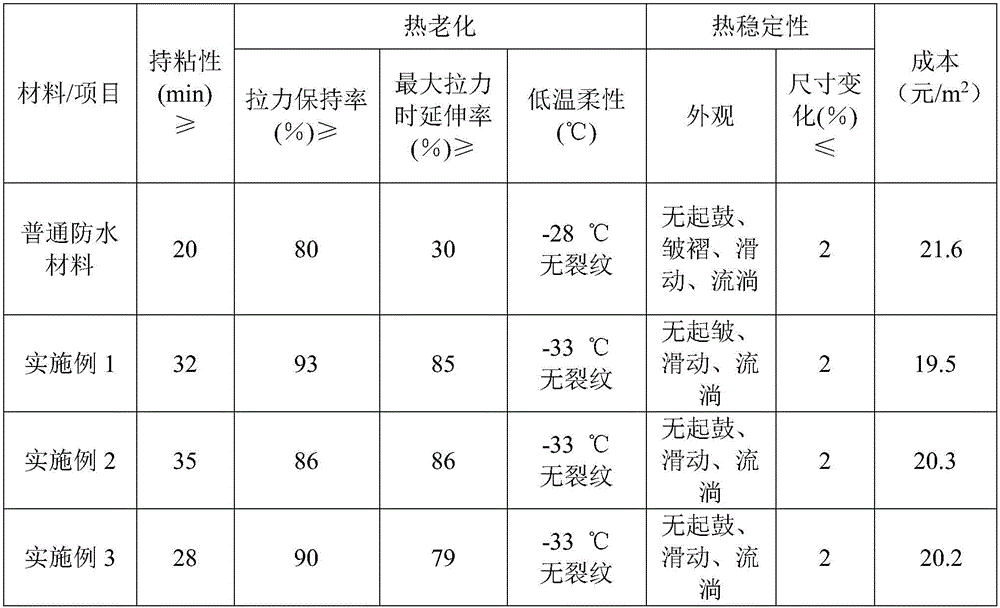

Embodiment 1

[0035] The preparation method of a kind of waterproof material of present embodiment, carry out according to the following steps:

[0036] 1. Add 40kg of 90# asphalt to the mixing tank, raise the temperature to 160°C, add 15kg of thermoplastic SBS rubber 1401, 12kg of activated rubber powder E4200, 15kg of basic rubber oil, 5kg of resin, 0.1kg of silane coupling agent KH550, and 0.2kg of surface active Agent 1831, heated up to 180°C while stirring, and stirred for 2 hours;

[0037] 2. After the mixed material in the mixing tank prepared in step 1 is melted, grind it once with a colloid mill or an emulsification pump until fully mixed;

[0038] 3. Cool down to 160°C, add 4kg of silicate mineral powder, stir for 1.5h, cool down to 125°C, and the waterproof material is obtained.

Embodiment 2

[0040] The preparation method of a kind of waterproof material of present embodiment, carry out according to the following steps:

[0041] 1. Add 50kg of 90# asphalt to the mixing tank, heat up to 155°C, add 20kg of thermoplastic SBS rubber 1401, 10kg of activated rubber powder E4200, 10kg of basic rubber oil, 3kg of resin, 0.1kg of silane coupling agent KH550, and 0.1kg of surfactant 1831, heat up to 185°C while stirring, and stir for 1.5h;

[0042] 2. After the mixed material in the mixing tank prepared in step 1 is melted, grind it twice with a colloid mill or an emulsification pump until fully mixed;

[0043] 3. Cool down to 155°C, add 5kg of silicate mineral powder, stir for 1.0h, and cool down to 120°C to obtain a waterproof material.

Embodiment 3

[0045] The preparation method of a kind of waterproof material of present embodiment, carry out according to the following steps:

[0046] 1. Add 60kg of 90# asphalt to the mixing tank, raise the temperature to 150°C, add 10kg of thermoplastic SBS rubber 1401, 8kg of activated rubber powder E4200, 20kg of basic rubber oil, 4kg of resin, 0.2kg of silane coupling agent KH550, and 0.1kg of surface active Agent 1831, heated up to 175°C while stirring, and stirred for 2 hours;

[0047] 2. After the mixed material in the mixing tank prepared in step 1 is melted, grind it twice with a colloid mill or an emulsification pump until fully mixed;

[0048] 3. Cool down to 165°C, add 7kg of silicate mineral powder, stir for 1.5h, cool down to 130°C, and the waterproof material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com