Uniform and stable separator oil and preparation method thereof

A separator and stable technology, applied in the field of separator oil and its preparation, can solve problems such as poor uniformity of separator oil, achieve the effects of excellent thermal stability, improve dispersibility, and reduce the possibility of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

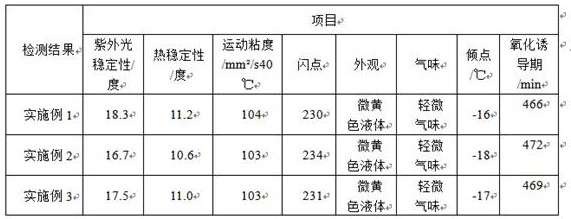

Examples

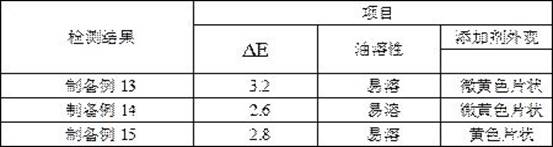

preparation example 1

[0038] Take p-methoxyphenol as high temperature antioxidant 1.

preparation example 2

[0040] Take 0.1kg of peroxidase, 500kg of phosphate buffer solution with pH=7, stir and mix to prepare a catalyst solution; take 30kg of p-methoxyphenol, 2kg of sodium dodecylbenzenesulfonate and 45kg of catalyst solution, and ultrasonically mix them for 10 minutes to prepare Obtain a mixed solution; respectively add 1 kg hydrogen peroxide and 1 kg sodium chloride to the mixed solution, heat up and stir, and suction filter to obtain a filter cake, wash with deionized water, and dry to obtain high-temperature antioxidant 2.

preparation example 3

[0042] Take 0.15kg peroxidase, 500kgPH=7 phosphate buffer solution, stir and mix to prepare the catalyst solution; take 40kg p-methoxyphenol, 3kg sodium dodecylbenzenesulfonate and 45kg catalyst solution, ultrasonically mix for 10min to prepare A mixed solution was obtained; 1.5 kg of hydrogen peroxide and 1.5 kg of sodium chloride were respectively added to the mixed solution, the temperature was raised and stirred, and suction filtered to obtain a filter cake, washed with deionized water and dried to obtain high-temperature antioxidant 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com