Self-rotating detachable easy-to-clean filter element

A detachable and self-rotating technology, which is applied in the field of air purification, can solve the problems of inconvenient cleaning of the filter body, achieve the effect of reducing cleaning dead angle, good capture, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

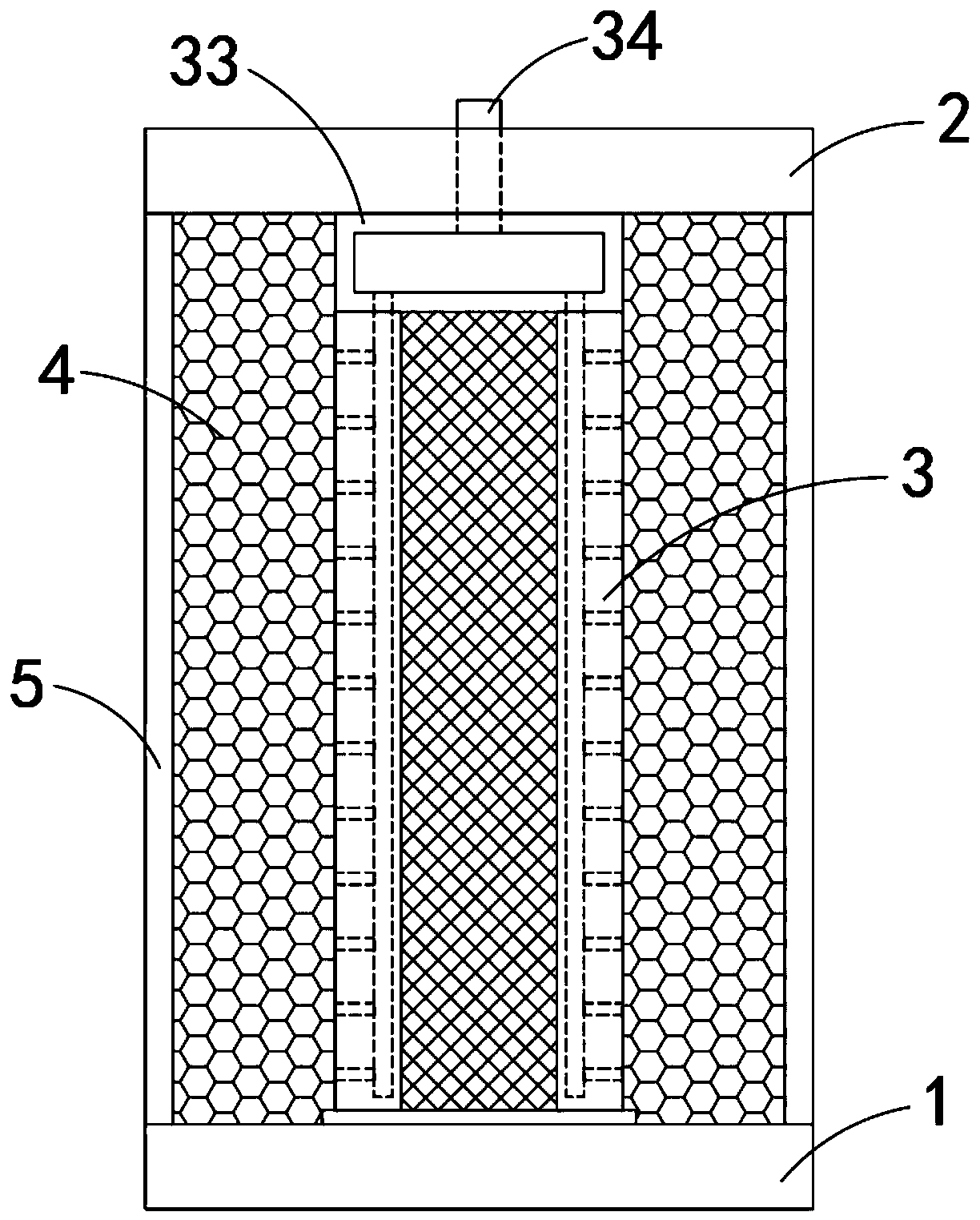

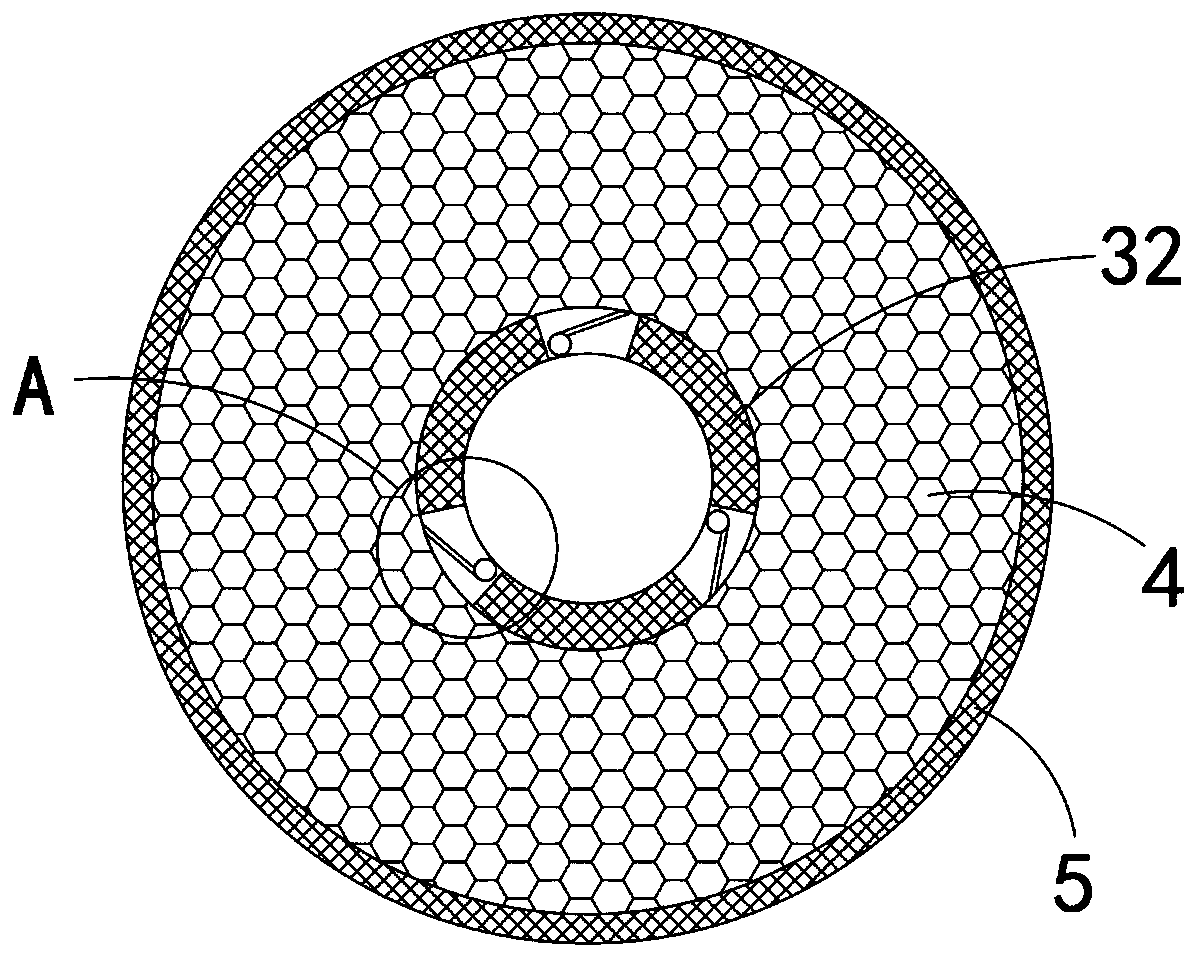

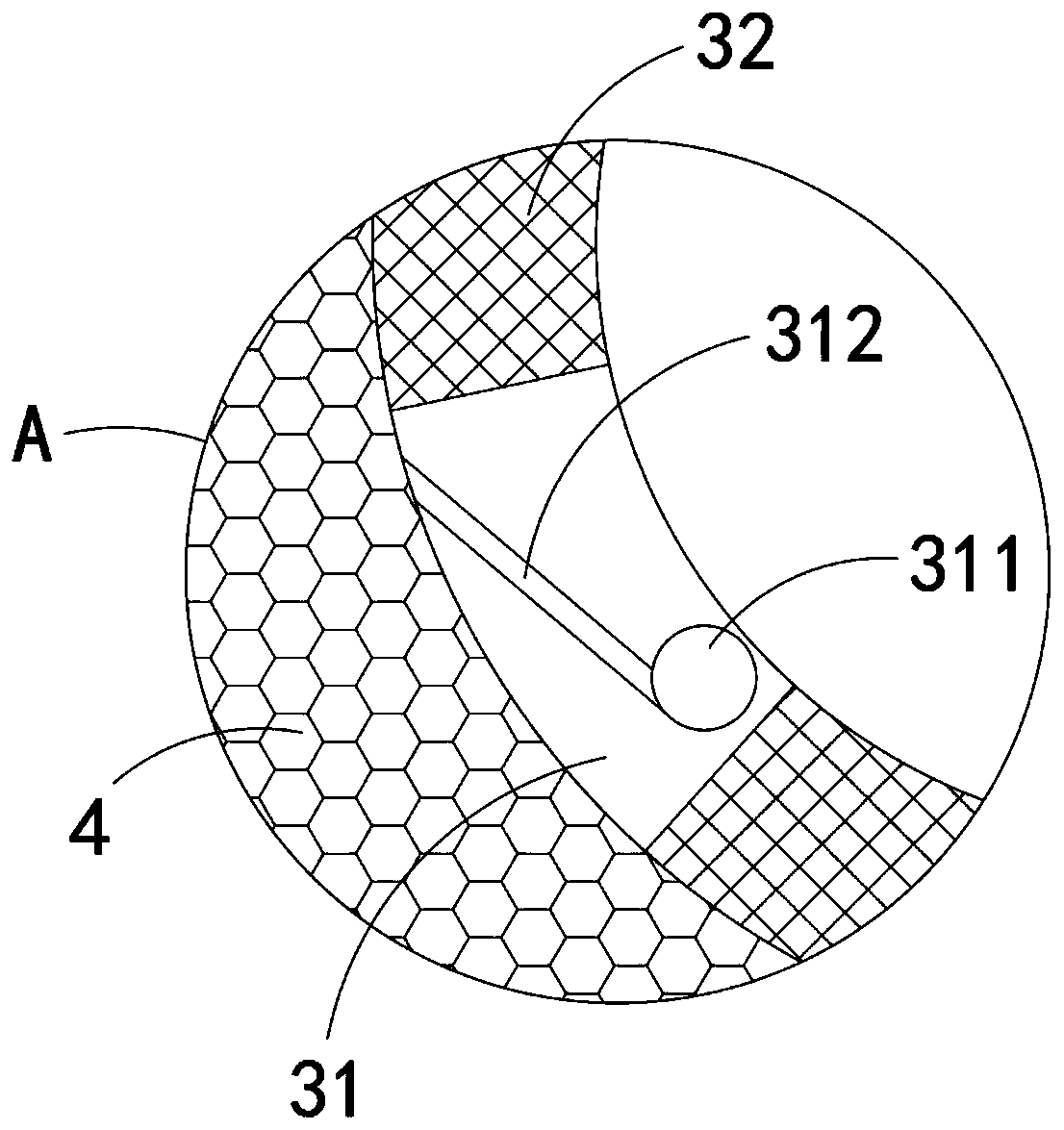

[0021] Such as Figure 1-3 As shown, a self-rotating detachable easy-to-clean filter element includes a base 1, a top seat 2, an inner cylinder 3, a filter element body 4 and an outer cylinder 5, the inner cylinder 3 can rotate freely along its axial direction, and the filter element body 4 is connected to the outer cylinder. The inner side wall of the tube 5 is fixedly connected, and the inner tube 3 includes a plurality of fixing bars 31 and filter screen plates 32 fixed between the fixing bars 31. The fixing bars 31 and the filter screen plates 32 are arc-shaped strips with the same radian. The fixed strip 31 and a plurality of filter screen plates 32 are fixedly connected together at intervals in turn to form an inner cylinder 3, the upper end of the inner cylinder 3 is fixedly connected with a rotating cylinder 33, and the rotating cylinder 33 is airtightly arranged for conducting airflow, and the upper end of the rotating cylinder 33 is fixed Connected with the air intak...

Embodiment 2

[0025] Such as Figure 4-5 As shown, the difference between the present embodiment and the first embodiment is that: the lower end of the inner cylinder 3 is fixedly connected with a friction ring 35 , and static electricity will be generated when friction occurs between the friction ring 35 and the base 1 .

[0026] In this embodiment, when the friction ring 35 rotates with the inner cylinder 3, it will rub against the base 1 and generate static electricity. Under the action of static electricity, it will absorb the blown dust particles, thereby preventing the dust from escaping everywhere. , causing secondary pollution to the surrounding environment.

[0027] Further, the outer cylinder 5 is provided with a plurality of strip-shaped slots with upward openings. Conductive strips 51 are arranged in the strip-shaped slots. The lower ends of each conductive strip 51 are connected to the base 1 in rotation. The curvature of the barrel 5 is consistent, and a plurality of discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com