PCB (Printed Circuit Board) visual inspection equipment

A PCB board and visual inspection technology, applied in the field of SMT processing and inspection equipment, can solve problems such as affecting the detection accuracy of PCB boards, and achieve the effects of improving detection accuracy, improving cleaning effect, and reducing cleaning dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

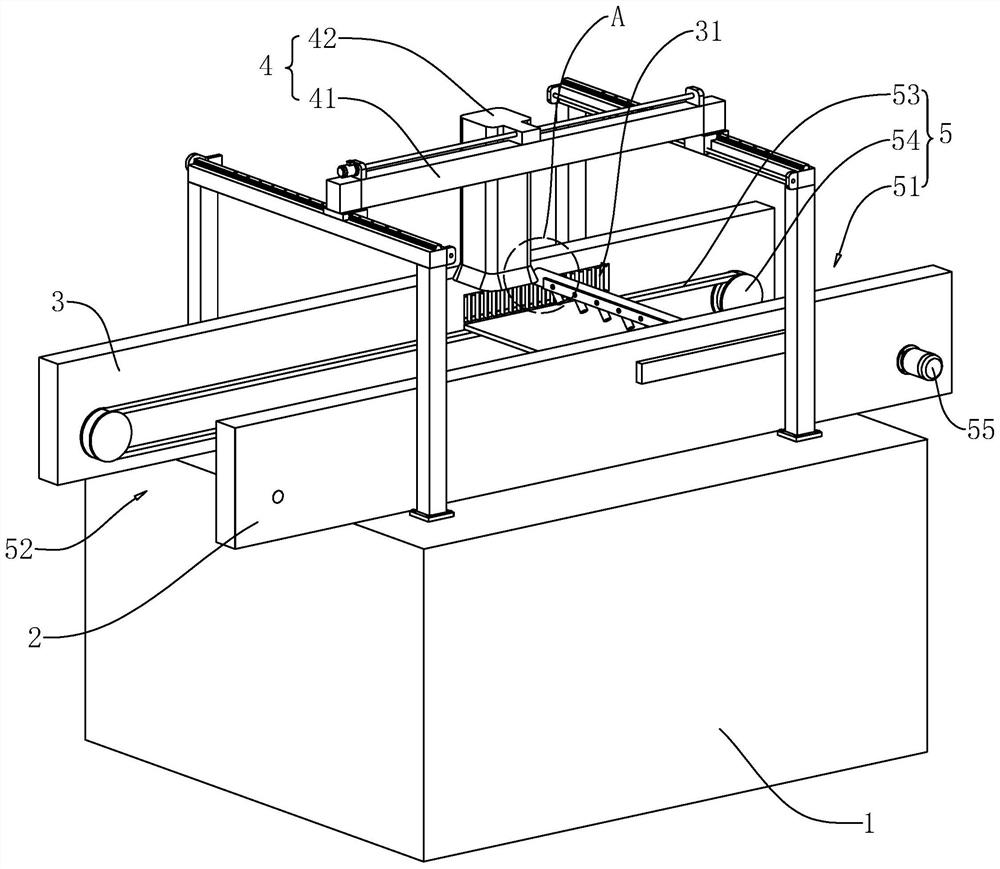

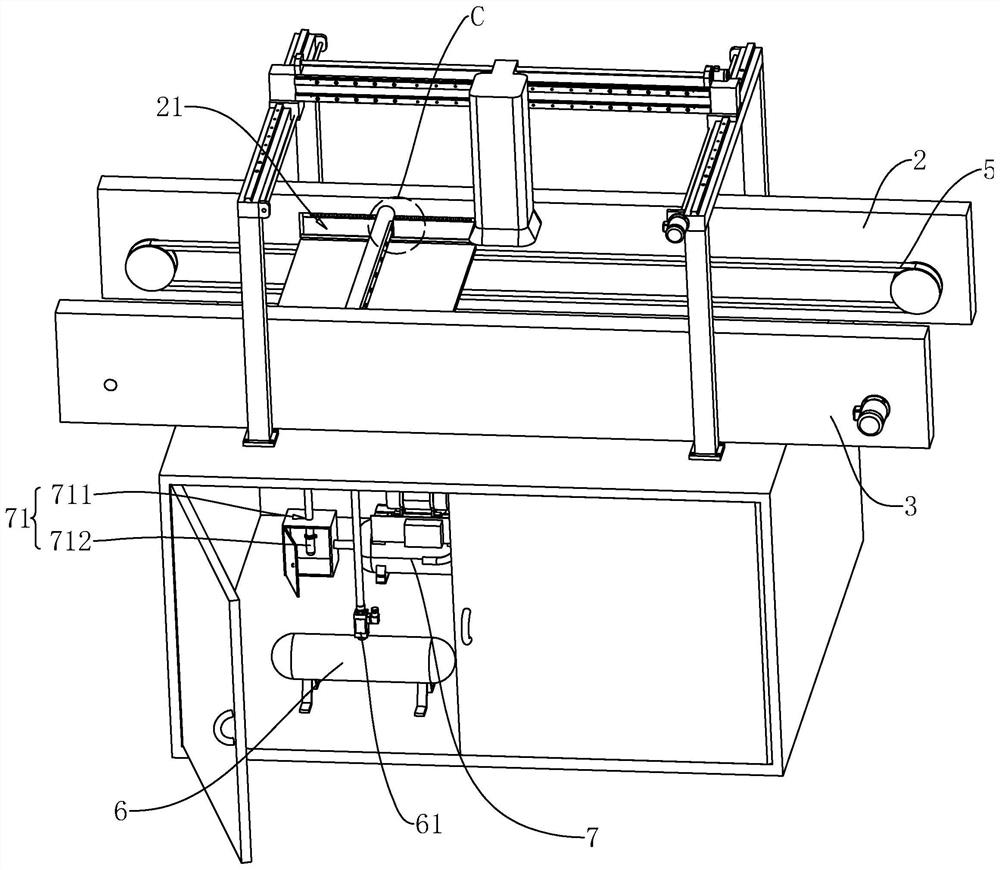

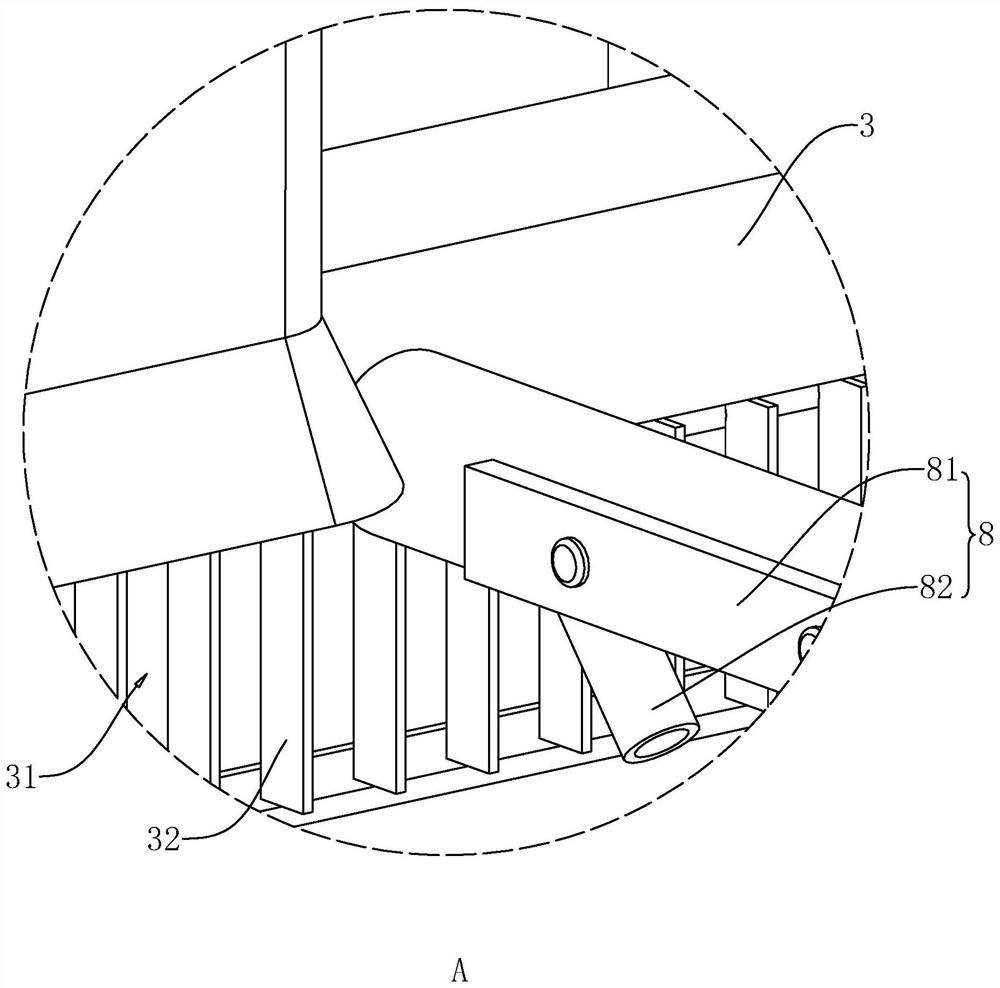

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a visual inspection device for a PCB board. refer to figure 1 , a kind of PCB board visual detection equipment comprises frame body 1, first track plate 2, second track plate 3, visual detection device 4 and cleaning device, and first track plate 2 and second track plate 3 are all bolted to frame body 1. The first track plate 2 and the second track plate 3 are arranged opposite to each other, and there is a passage for the PCB board to pass between the first track plate 2 and the second track plate 3 . The opposite board surfaces of the first track plate 2 and the second track plate 3 are all provided with a transfer rail 5, the transfer rail 5 has a feed port 51 and a discharge port 52, and the transfer rail 5 is used to transfer the PCB board to the visual inspection device 4. detection position. Before the conveying ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com