Epitaxial slice cleaning device

A cleaning device and a technology for epitaxial wafers, which are applied in the directions of dry gas arrangement, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems affecting the quality of epitaxial wafers, low manual cleaning efficiency, and easy residual pollutants, etc. The effect of cleaning dead corners, preventing recontamination, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

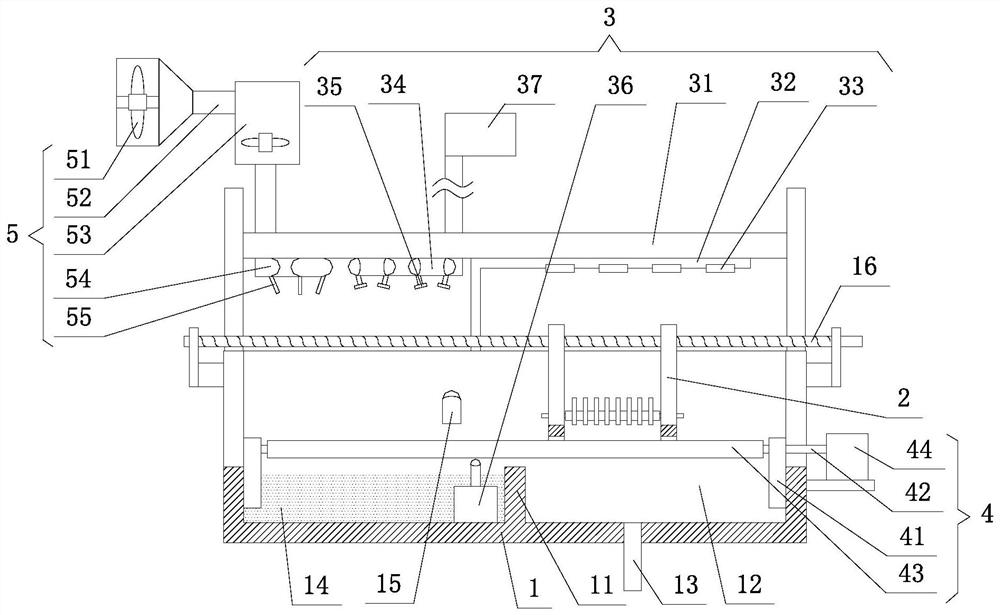

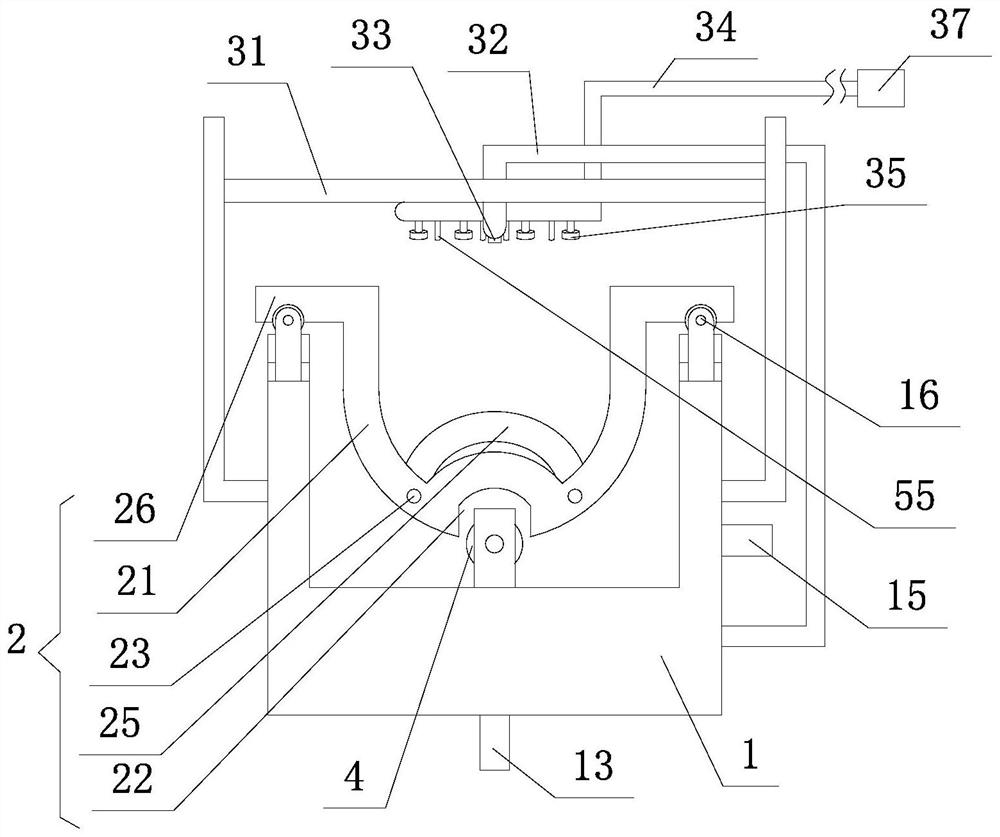

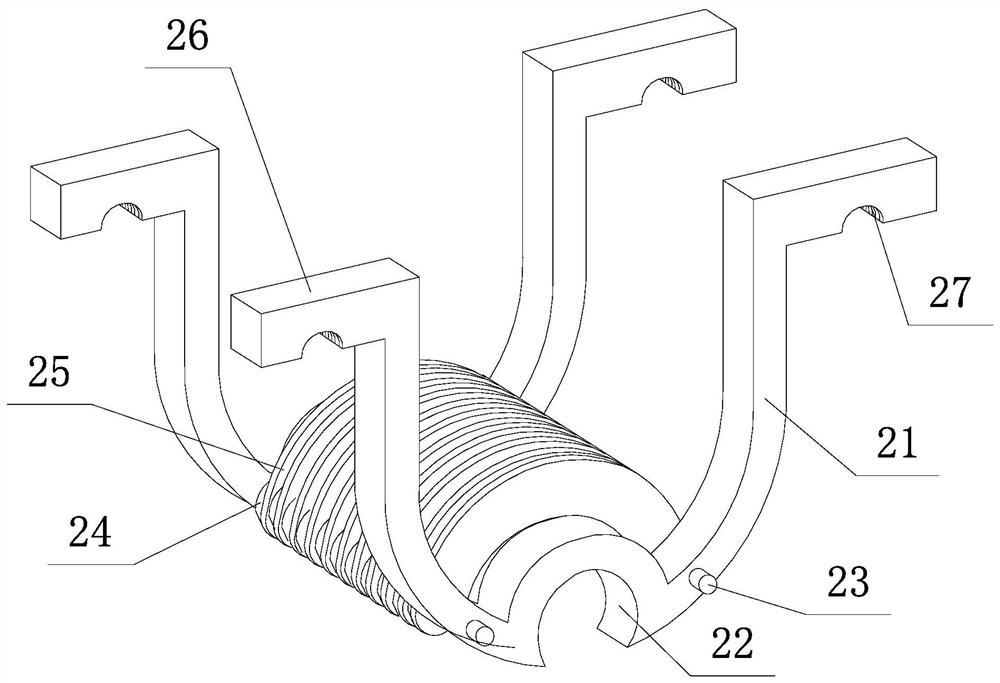

[0021] Such as Figure 1 ~ Figure 3 As shown, the epitaxial wafer cleaning device provided in this embodiment includes a cleaning pool 1, a carriage 2, a cleaning mechanism 3, a rotating mechanism 4, and a drying mechanism 5. The cleaning pool 1 is rectangular, and the cleaning pool 1 is along its length direction. The middle part is provided with a partition 11 to separate the cleaning pool 1 into an initial washing area 12 and a fine washing area 14. A drain pipe 13 is connected to the bottom of the initial washing area 12, and a liquid supply pipe 15 is installed in the fine washing area 14. The top of the side wall on both sides of the cleaning tank 1 along its length direction is provided with a horizontal and rotatable screw mandrel 16, and the screw mandrel 16 is provided with a carriage 2 that can slide on the cleaning tank 1, and the carriage 2 2. It includes U-shaped frame 21, connecting rod 23, rubber sleeve 24, partition bar 25 and slider 26. The U-shaped frame 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com