Process for arranging drill holes in spontaneous combustion coal seam to implement nitrogen injection and grouting fire prevention and extinguishing

A technology for fire prevention and nitrogen injection, which is used in fire prevention, dust prevention, safety devices, etc., can solve problems such as inability to accurately grasp the range and accuracy of nitrogen injection, difficulty in hosting and pulling, loss and diffusion, etc., to eliminate spontaneous combustion and ignition of coal seams. hidden dangers, shorten the oxidation zone, and reduce the effect of oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

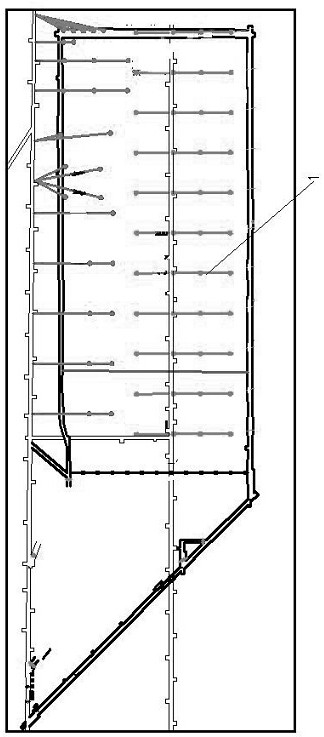

[0019] like figure 1 As shown in Fig. 1, the drill holes are arranged in the self-combustible coal seam to implement nitrogen injection and grouting to prevent and extinguish the fire, including the following steps:

[0020] 1) Units are divided according to the direction and inclination of the coal mining face and the three-zone conditions of the goaf, and each 40m is a unit, and the layout of the dual-purpose drilling 1 is determined in the unit, and the distance between the final holes of the dual-purpose drilling 1 is 30m ;

[0021] 2) When the initial mining of the coal mining face is completed, a dual-purpose borehole 1 is drilled at the cutting hole of the working face;

[0022] 3) When the one-hole dual-purpose borehole 1 in each unit section enters the goaf for 35m, the one-hole dual-purpose borehole 1 is merged into the nitrogen injection pipeline system, and preventive nitrogen injection and fire prevention measures are implemented;

[0023] 4) According to the sp...

Embodiment 2

[0028] like figure 1 As shown in Fig. 1, the drill holes are arranged in the self-combustible coal seam to implement nitrogen injection and grouting to prevent and extinguish the fire, including the following steps:

[0029] 1) Units are divided according to the direction and inclination of the coal mining face and the three-zone conditions of the goaf, and each 40m is a unit, and the layout of the dual-purpose drilling 1 is determined in the unit, and the distance between the final holes of the dual-purpose drilling 1 is 30m ;

[0030] 2) When the initial mining of the coal mining face is completed, a dual-purpose borehole 1 is drilled at the cutting hole of the working face;

[0031] 3) When the one-hole dual-purpose borehole 1 in each unit section enters the goaf for 40m, the one-hole dual-purpose borehole 1 is merged into the nitrogen injection pipeline system, and preventive nitrogen injection and fire prevention measures are implemented;

[0032] 4) According to the sp...

Embodiment 3

[0036] like figure 1 As shown in Fig. 1, the drill holes are arranged in the self-combustible coal seam to implement nitrogen injection and grouting to prevent and extinguish the fire, including the following steps:

[0037] 1) Units are divided according to the direction and inclination of the coal mining face and the three-zone conditions of the goaf, and each 40m is a unit, and the layout of the dual-purpose drilling 1 is determined in the unit, and the distance between the final holes of the dual-purpose drilling 1 is 30m ;

[0038] 2) When the initial mining of the coal mining face is completed, a dual-purpose borehole 1 is drilled at the cutting hole of the working face;

[0039] 3) When the one-hole dual-purpose borehole 1 in each unit section enters the goaf for 37m, the one-hole dual-purpose borehole 1 is merged into the nitrogen injection pipeline system, and preventive nitrogen injection and fire prevention measures are implemented;

[0040] 4) According to the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com