A whole life cycle treatment method for tunnel water inrush

A full-life cycle, water inrush technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of inability to ensure the stability of surrounding rocks, consume manpower, material resources, and financial resources, and tunnel inconvenience, and achieve the determination of excavation time The method is scientific, conducive to standardization, and the effect of reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

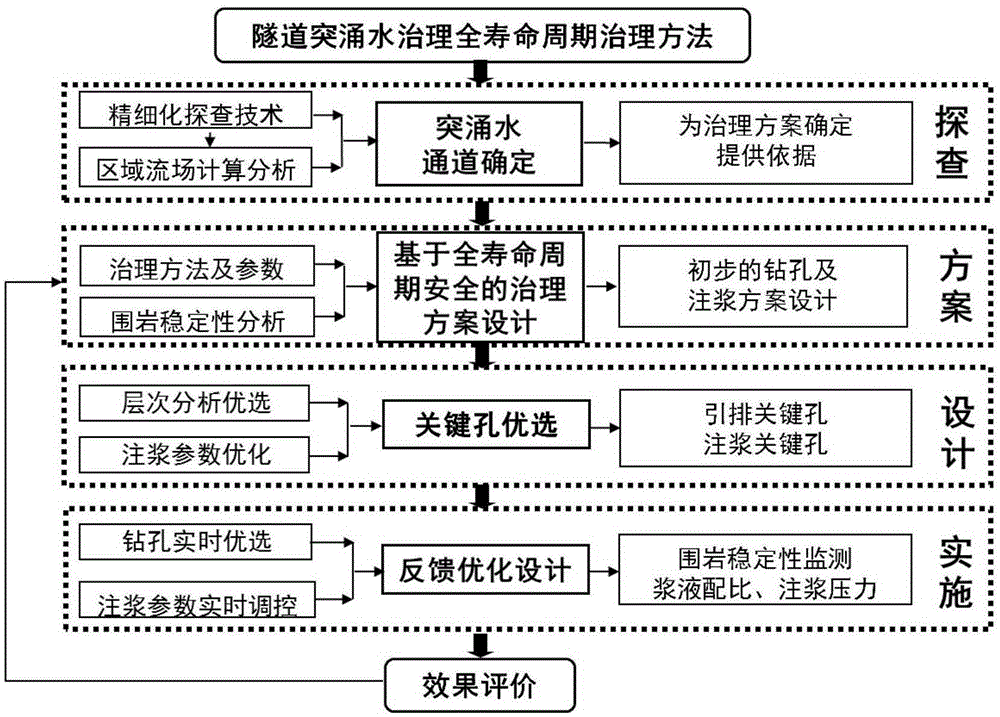

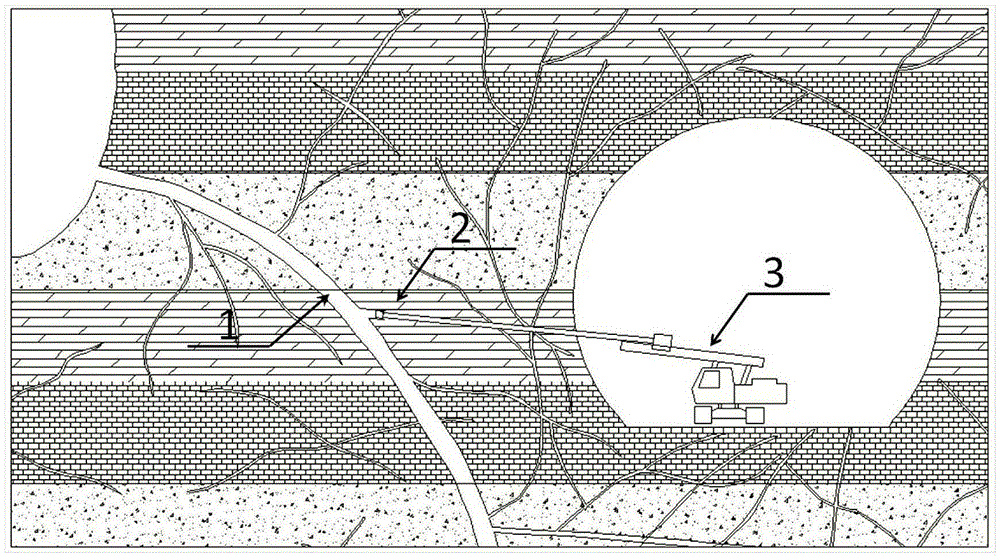

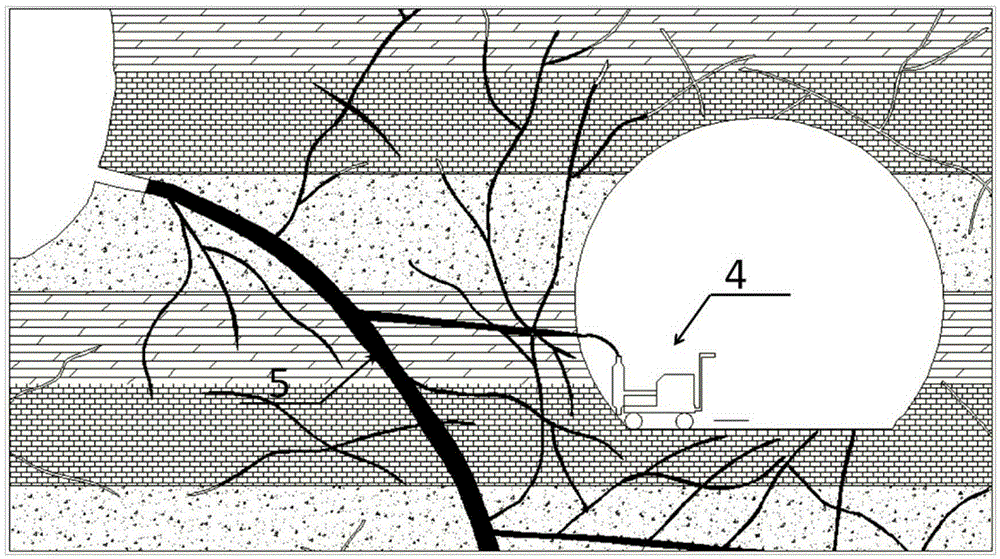

[0055] Such as figure 1 As shown, the present invention is aimed at the treatment process of water inrush during the construction period of the tunnel project and leakage water disaster during the operation period. , transient electromagnetic, high-density electrical method and cross-hole CT comprehensive geophysical fine-grained exploration technology, combined with regional process calculation and analysis, to obtain the three-dimensional shape and flow field characteristics of the water guide channel, and provide a basis for the treatment plan. On the basis of determining the water inrush channel, based on the small-area connection test, the borehole pressure water test and the coupled numerical simulation of the grout-surrounding rock, different types of water inrush control methods and parameters are obtained, and the stability analysis of the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com