VAD prepared large-core optical fiber parent metal blast burner

An optical fiber base material, large core diameter technology, applied in glass manufacturing equipment, manufacturing tools, glass production and other directions, can solve the problems of raw material loss, high speed, affecting deposition efficiency, etc., to improve production efficiency, suppress divergence, prevent Lost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

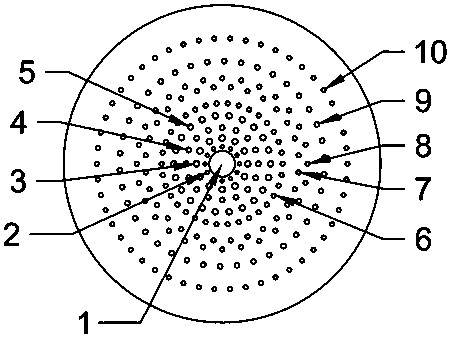

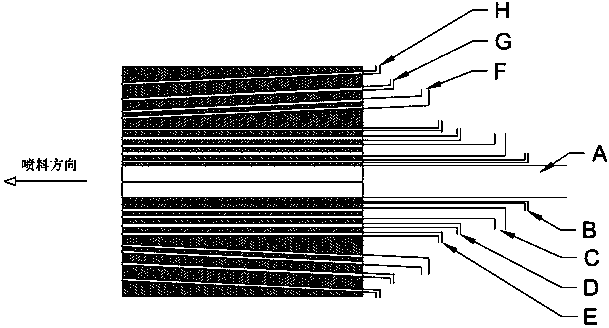

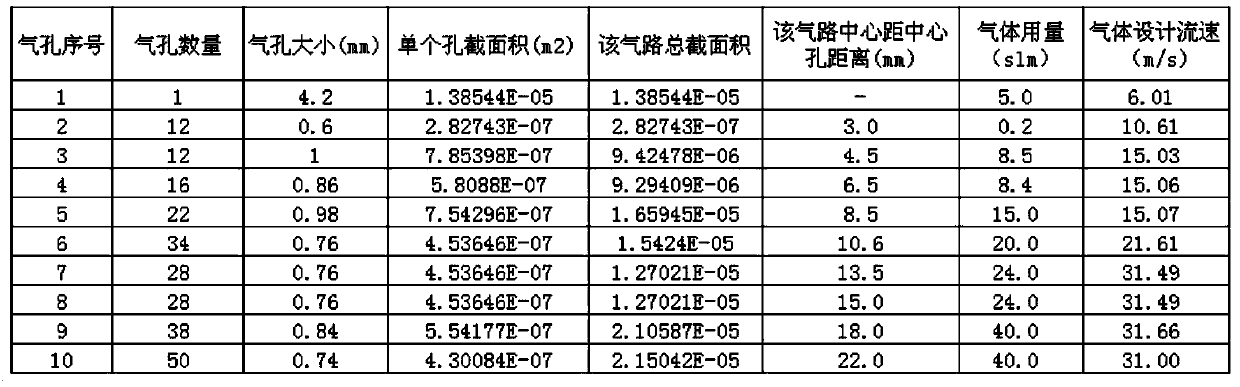

[0017] It includes a cylindrical blowtorch body, and the center of the blowtorch body is provided with a central feeding hole 1, the diameter of which is 4.2mm, which is used to feed silicon tetrachloride and germanium tetrachloride raw materials for the reaction, and the feeding tube The A phase is connected; the multi-layer annular distribution air holes are arranged around the central feeding hole in the circumferential direction, and the multi-layer annular distribution air holes include the inner layer isolation air hole, the inner layer flame air hole, the outer layer isolation air hole and the outer layer flame from the inside to the outside. Stomata, the inner isolation pores 2 and the outer isolation pores 6 are each one layer, which are pores that do not participate in the reaction gas, and communicate with the nitrogen and helium pipelines B that do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com