Biomass granular fuel cooking warm range

A biomass particle and fuel technology, applied in the field of stoves, can solve the problems of environmental pollution, large waste discharge, waste of energy, etc., and achieve the effect of small environmental pollution, low emission cost application, and low cost application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the drawings and specific embodiments:

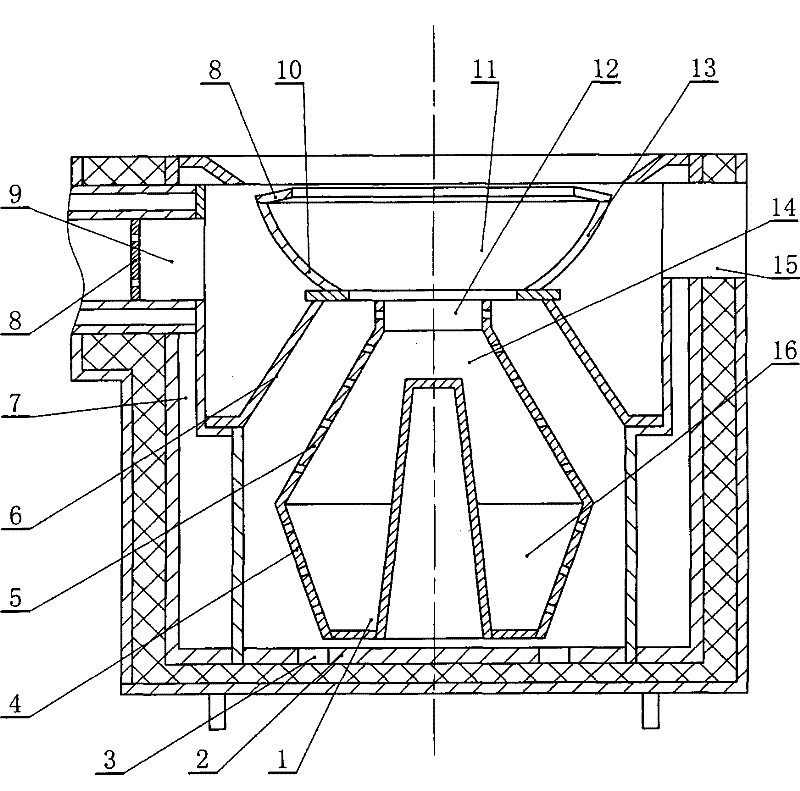

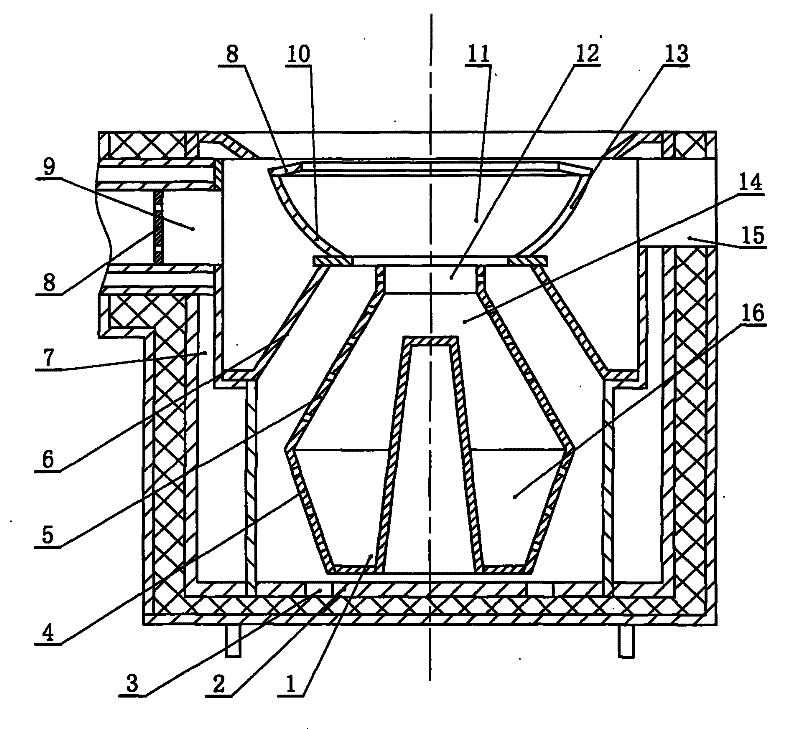

[0008] A biomass pellet fuel cooking and heating stove, such as figure 1 As shown, it includes the furnace shell, the upper side wall of the furnace shell is equipped with an exhaust gas discharge cylinder 9, and the furnace shell is equipped with a furnace, and the furnace chamber communicates with the exhaust gas discharge cylinder 9, and a furnace mouth cover ring is installed on the furnace shell at the upper mouth of the furnace. A bottom plate flat grate 2 is installed in the lower part of the furnace in the furnace shell. The bottom plate flat grate 2 is provided with a secondary oxygen inlet hole 3 for the core support plate. A furnace core is installed in the furnace inside the furnace shell above the bottom plate flat grate 2. Including cone vertical grate 1, anti-cone porous core shell 4, positive cone porous core shell 5, porous combustion cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com