Horizontal hot water boiler

A hot water boiler and horizontal technology, applied in the field of hot water boilers, can solve the problems of affecting the combustion state of fuel, not being strong enough, falling on the coal seam, etc., and achieve the effects of increasing the service life, alleviating the burden, and facilitating the removal of carbon deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

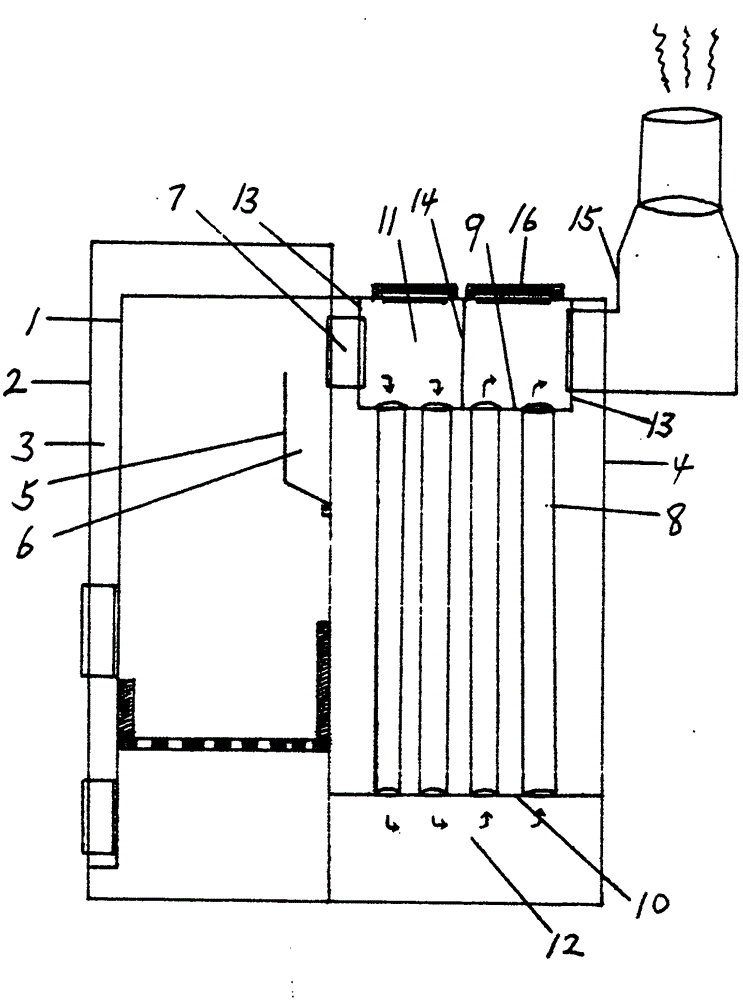

[0015] The invention is divided into two parts, a relatively independent combustion chamber and a radiator. Above the combustion chamber, there is a buffer plate 5 and a settling chamber 6 formed by the buffer plate. There is a high-temperature flue gas outlet 7 leading to the smoke chamber on the first stroke of the radiator near the radiator.

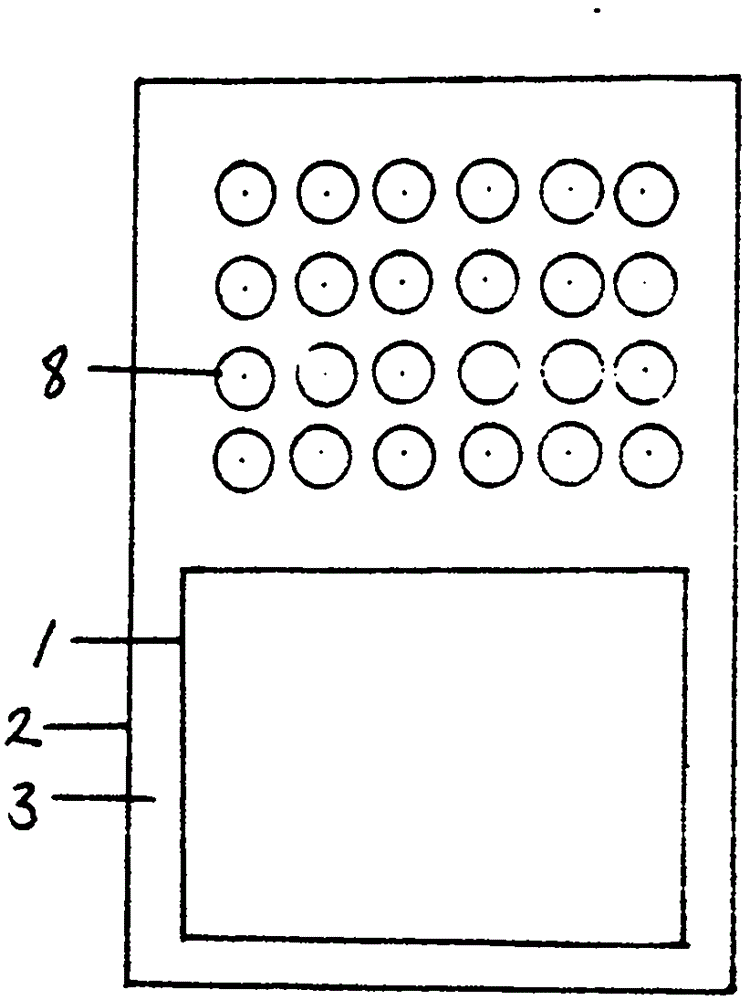

[0016] Between the combustion chamber liner 1 and the shell 2 is a membrane-type water-cooled wall 3, and the top of the combustion chamber is also a membrane-type water-cooled wall. The shell 4 of the heat absorber and the shell of the combustion chamber are essentially an integrated structure. The working medium in the shell of the device is also the same.

[0017] The pyrotechnic tube bundle composed of pyrotechnic tubes 8 is between the upper tube plate 9 and the lower tube plate 10, the upper tube plate is the upper smoke chamber 11, and the lower tube plate is the lower smoke chamber 12. The carbon deposits removed from the pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com