Horizontal fire tube boiler with tail provided with gas-water heat tube heat exchange tube

A technology of fire tube boilers and water heat pipes, applied in steam boilers, water heaters, fluid heaters, etc., can solve problems such as shutdown, maintenance and replacement, and achieve the effects of saving space, compact structure, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

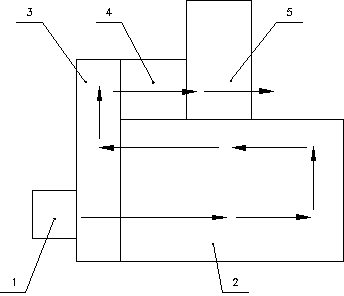

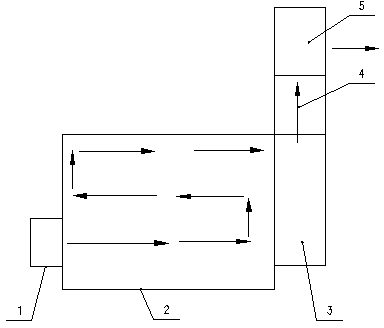

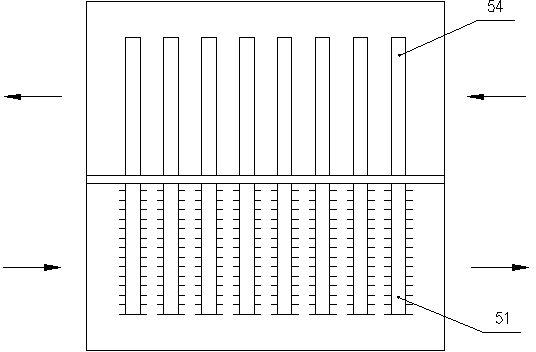

[0027] see figure 1 with figure 2 , figure 1 It is a schematic flow chart of a horizontal fire tube boiler with a gas-water heat pipe heat exchanger at the end of the three-pass process of the present invention. figure 2 It is a schematic flow diagram of a horizontal fire tube boiler with a gas-water heat pipe heat exchanger at the end of the two return passes of the present invention. Depend on figure 1 with figure 2 It can be seen that the horizontal fire tube boiler with gas-water heat pipe heat exchange tube at the tail of the present invention is mainly composed of a burner 1, a boiler body 2, a turning smoke chamber 3, an economizer 4 and a gas-water heat pipe heat exchanger 5 . The burner 1 is set at the front end of the boiler body 2 of the two-pass or three-pass horizontal fire tube boiler, the economizer 4 is set at the top of the boiler body, the gas-water heat pipe heat exchanger 5 is added behind the economizer 4, and the gas-water The heat pipe heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com