Fuel gas combustion system suitable for fire tube boiler

A technology of gas combustion and fire tube boilers, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., which can solve the problems of underutilized boiler furnace space, difficulty in achieving ultra-low NOx emissions, and heat transfer effects of fire tube boilers To achieve the effect of excellent stable combustion ability, complete combustion, and less CO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

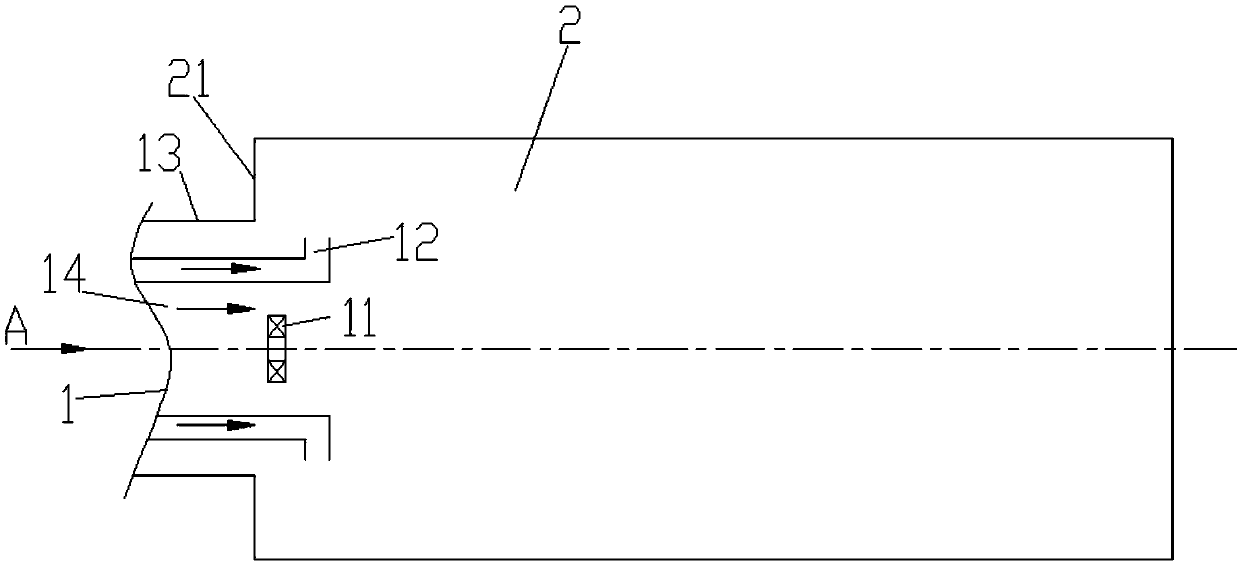

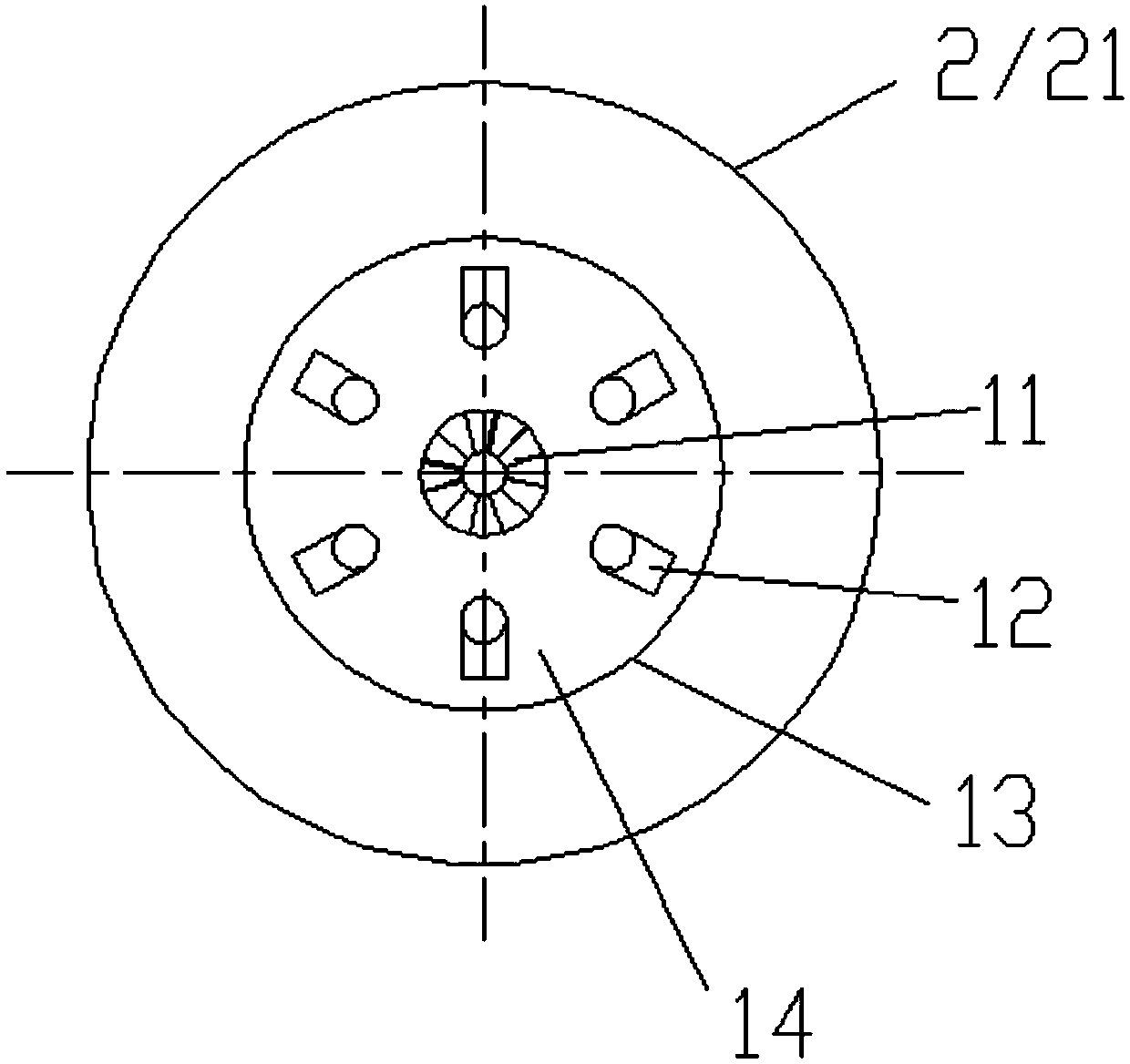

[0020] figure 1 and figure 2 It is a schematic structural diagram of the present invention, and it can be seen from the diagram that a gas combustion system suitable for a fire tube boiler includes a low-nitrogen burner 1 and a boiler furnace 2, and the low-nitrogen burner 1 is arranged on the boiler front wall 21 of the boiler furnace 2; It is characterized in that: the low-nitrogen burner 1 includes a flame stabilization plate 11, a gas gun 12, a burner throat 13 and a combustion air passage 14, and the flame stabilization plate 11, the gas gun 12, the burner throat, and 13 are composed of The central axis of the burner is arranged symmetrically outward in sequence; the combustion air channel 14 is placed in the throat 13 of the burner.

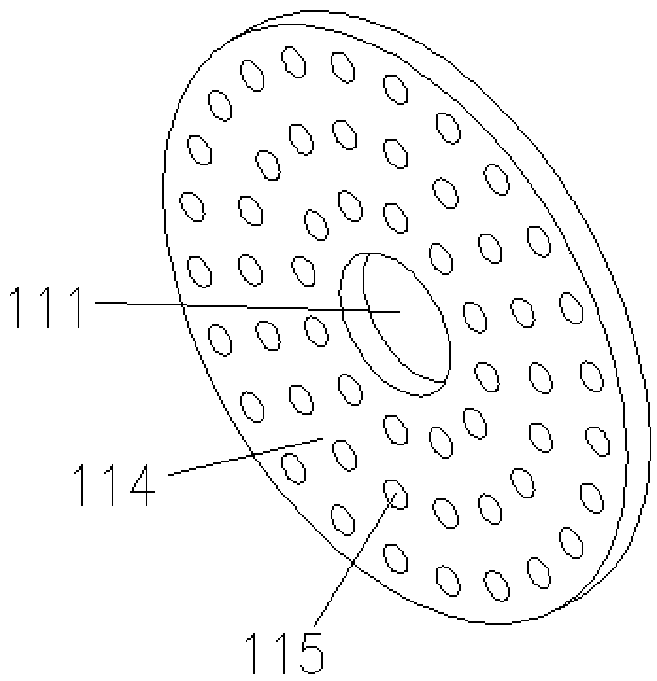

[0021] The main body of the flame stabilizing plate 11 is circular, which is a circular f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com