Garbage coal-powder compound burning-incinerating furnace

A technology for incinerators and garbage coal, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of low combustible content, unstable garbage, and incomplete decomposition of harmful components, etc., to achieve convenient operation, easy promotion and application, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

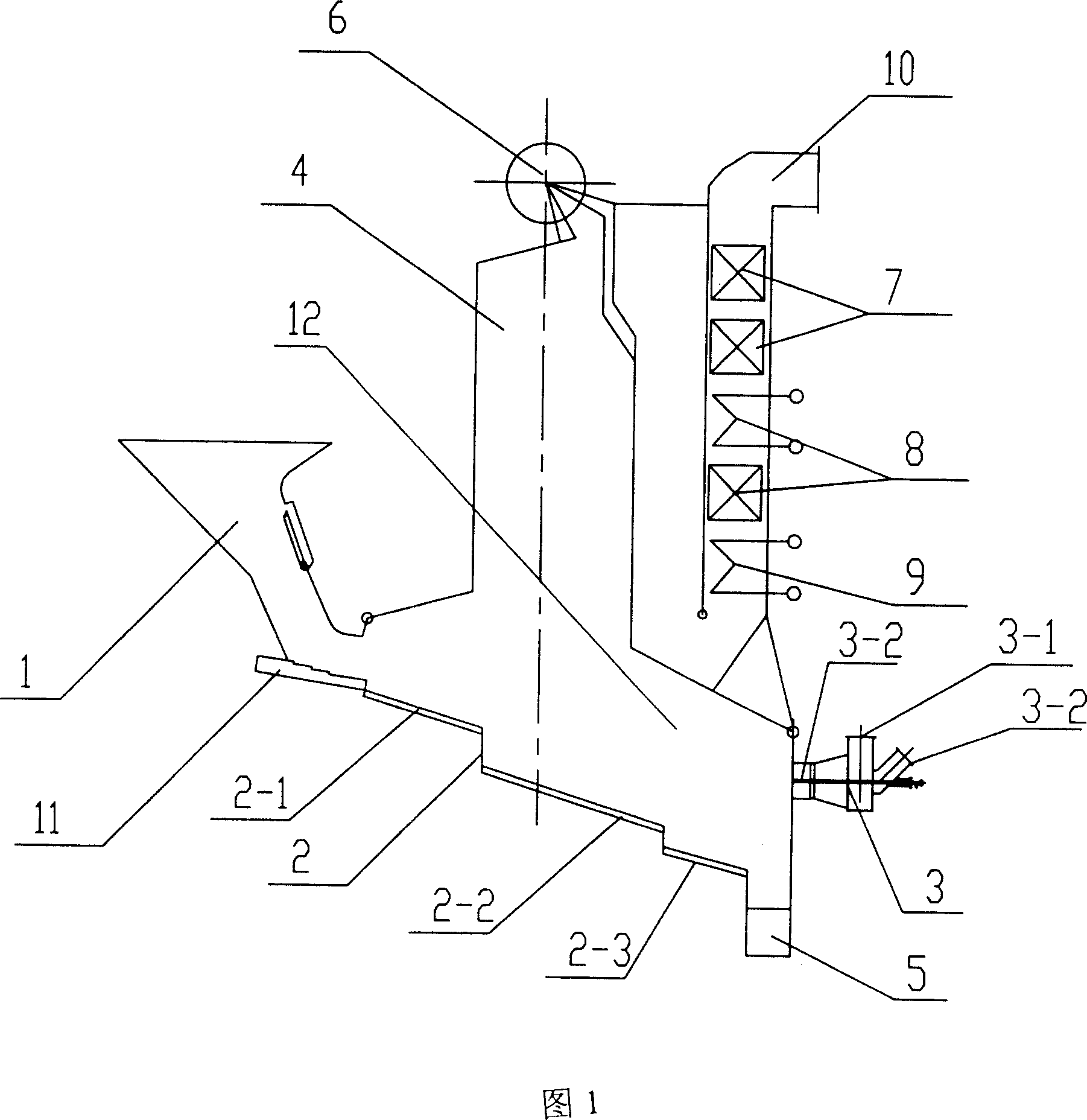

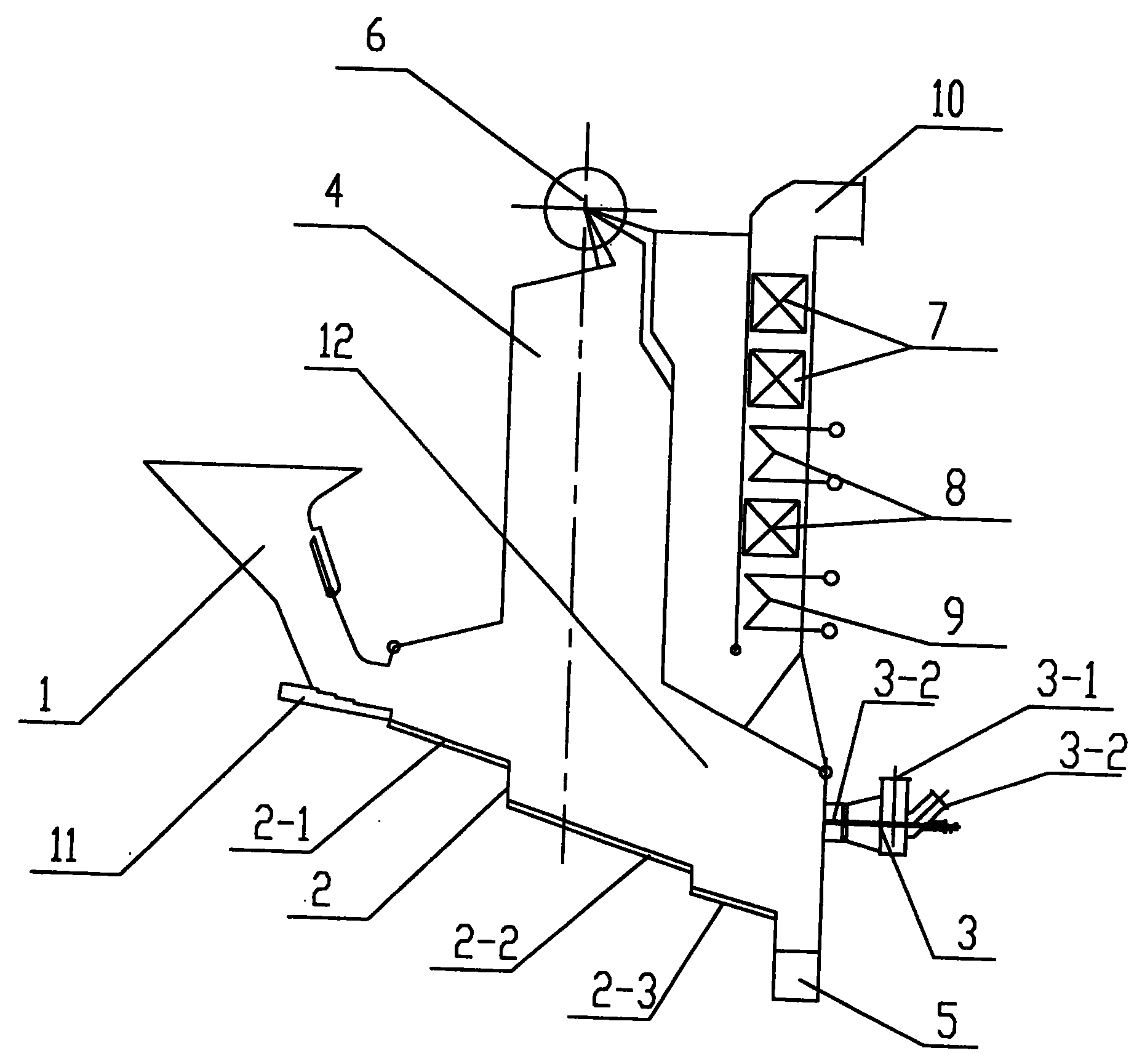

[0010] Garbage pulverized coal composite combustion incinerator, as shown in Figure 1, it includes a feed hopper 1, a feeder 11, a fire grate 2, a slag outlet 5, a burner 3, and a steam drum 6, an air preheater 7. In the waste heat furnace 4 composed of economizer 8, the space above the waste incineration layer formed by the drying section 2-1, combustion section 2-2 and burnout section 2-3 of the grate is the pulverized coal combustion space 12, and the pulverized coal Install one or more low NO x The swirl pulverized coal burner 3 is made up of a primary air duct 3-2 and a secondary air duct 3-1. The pulverized coal is sprayed into the furnace by the primary air duct for combustion, and the secondary air duct supplements the required air for combustion.

[0011] When working, the garbage is sent to the grate 2 from the feeder 1 through the feeder 11, and after being incinerated by the drying section 2-1, the burning section 2-2, and the burnout section 2-3, the ash is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com