Swirl Pulverized Coal Burner Inner Shrinking Outer Expansion Nozzle

A pulverized coal burner and retractable technology, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve the problem of reducing the ignition and stable combustion performance of the pulverized coal gas flow of the nozzle, impairing the ignition and stable combustion performance of pulverized coal, Boiler safety operation requirements hidden dangers and other issues, to achieve good application prospects, strengthen ignition and stable combustion performance, and avoid the effect of pulverized coal concentration dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

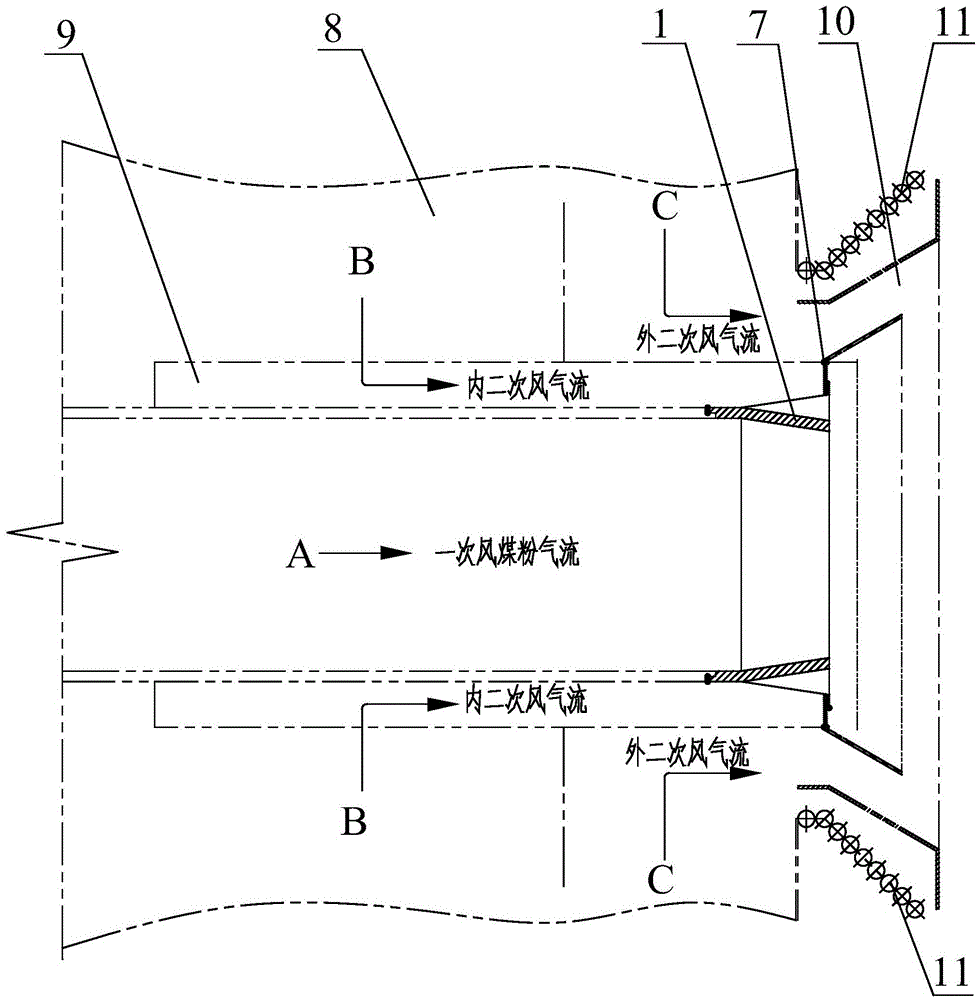

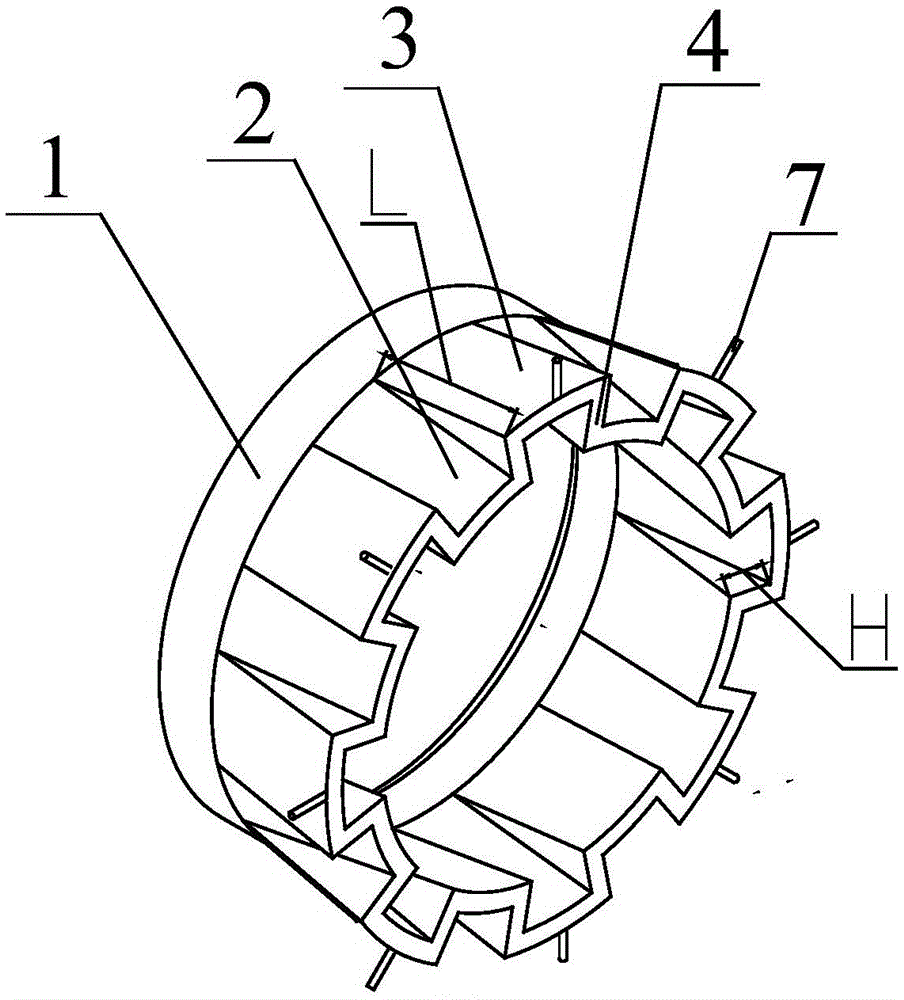

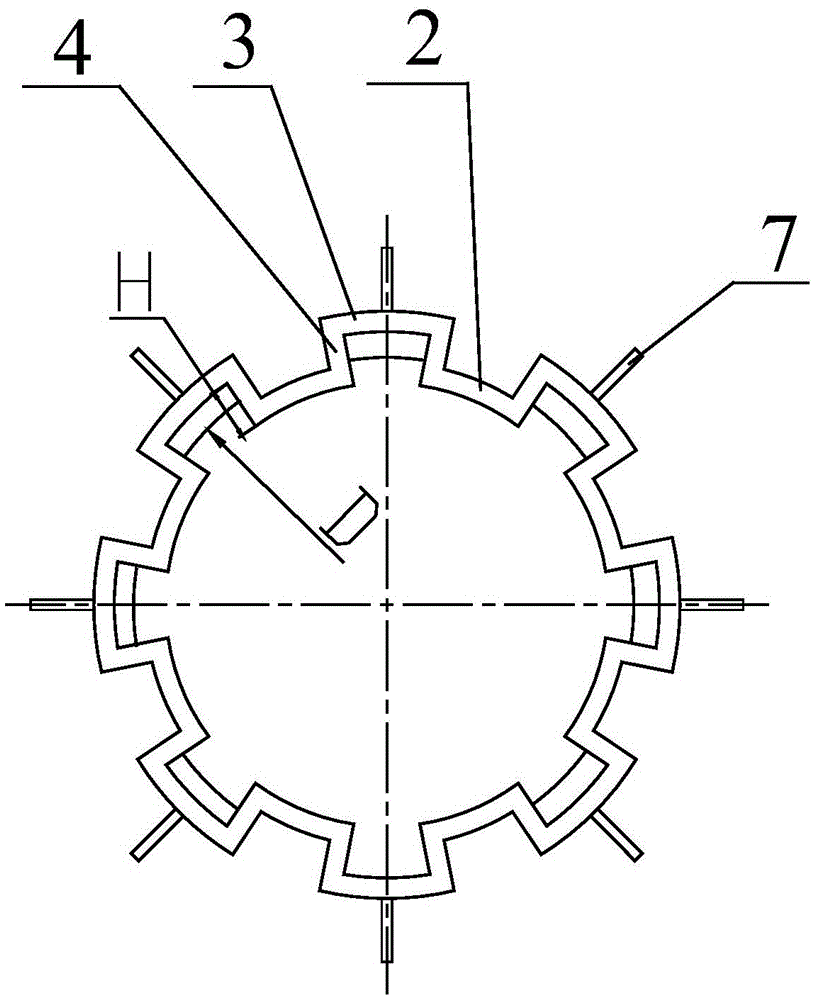

[0029] Such as Figure 2~3 A swirl pulverized coal burner shown in the figure has a shrinking and expanding nozzle, which has a nozzle body 1. The nozzle section of the nozzle body 1 has a double-sided battlement diversion structure, and it includes retractable guide vanes 2 arranged staggered along the circumferential direction. And the outwardly expanding guide vane 3, the retractable guide vane 2 is based on the inner diameter D of the nozzle section of the nozzle body 1, and the section radius from the root to the end is gradually reduced, and the outwardly expanding guide vane 3 is based on the nozzle The inner cavity diameter D of the nozzle section of the body 1 is based on the cross-sectional radius from the root to the end gradually increases, and the radial transition plate of the triangular structure is passed between the adjacent retractable guide vanes 2 and the outwardly expanded guide vanes 3 4 in one.

[0030] When optimizing the design, the inner cavity diame...

Embodiment 2

[0034] Such as Figure 4~5Another kind of swirl pulverized coal burner shown is the shrinking and expanding nozzle, its overall structure is basically the same as that of Embodiment 1, except that the outer side of the end of the shrinking deflector 2 is welded with a shrinking end stable combustion block The sheet 5 and the internally retracted end combustion stabilizing baffle 5 are arranged perpendicular to the axis line of the nozzle section of the nozzle body 1 . When optimizing the design, the radial height h1 of the combustion-stabilizing baffle 5 at the retracted end and the radial height H from the inner wall of the retracted guide vane 2 to the inner wall of the expanded guide vane 3 satisfy the following mathematical relationship: h1= 0.5~1.0H. In this embodiment, h1=0.8H. The internally retracted end combustion stabilizing baffle 5 can effectively prevent the internal secondary air flow B from entering the primary air pulverized coal flow A prematurely, thereby a...

Embodiment 3

[0036] Such as Figure 6~7 The third kind of swirl pulverized coal burner shown is the shrinking and expanding nozzle. Its overall structure is basically the same as that of Embodiment 1, except that the outside of the end of the expanding deflector 3 is welded with an expanding end stable combustion block. The sheet 6 and the flame-stabilizing baffle at the outer expansion end are arranged perpendicular to the axis line of the nozzle section of the nozzle body 1 . When optimizing the design, the radial height h2 of the combustion-stabilizing baffle 6 at the outer expansion end and the radial height H from the inner wall of the retractable guide vane 2 to the inner wall of the outward expansion guide vane 3 satisfy the following mathematical relationship: h2= 0.5~2.0H. In this embodiment, h2=0.9H. The externally expanded end combustion stabilization baffle 6 can effectively prevent the internal secondary air flow B from entering the primary air pulverized coal flow A prematu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com