Multi-directional jet swirl pulverized coal burner

A pulverized coal burner and jet type technology, which is applied to burners, burners burning powder fuels, and burning with various fuels, etc., can solve the hidden dangers of safe and stable operation of boilers, hidden dangers of high temperature corrosion of water walls, and lack of oxygen in pulverized coal. Combustion and other problems, to avoid high-temperature corrosion and scouring of pulverized coal gas flow, to eliminate high-temperature corrosion and coking hidden dangers, and to strengthen the performance of ignition and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

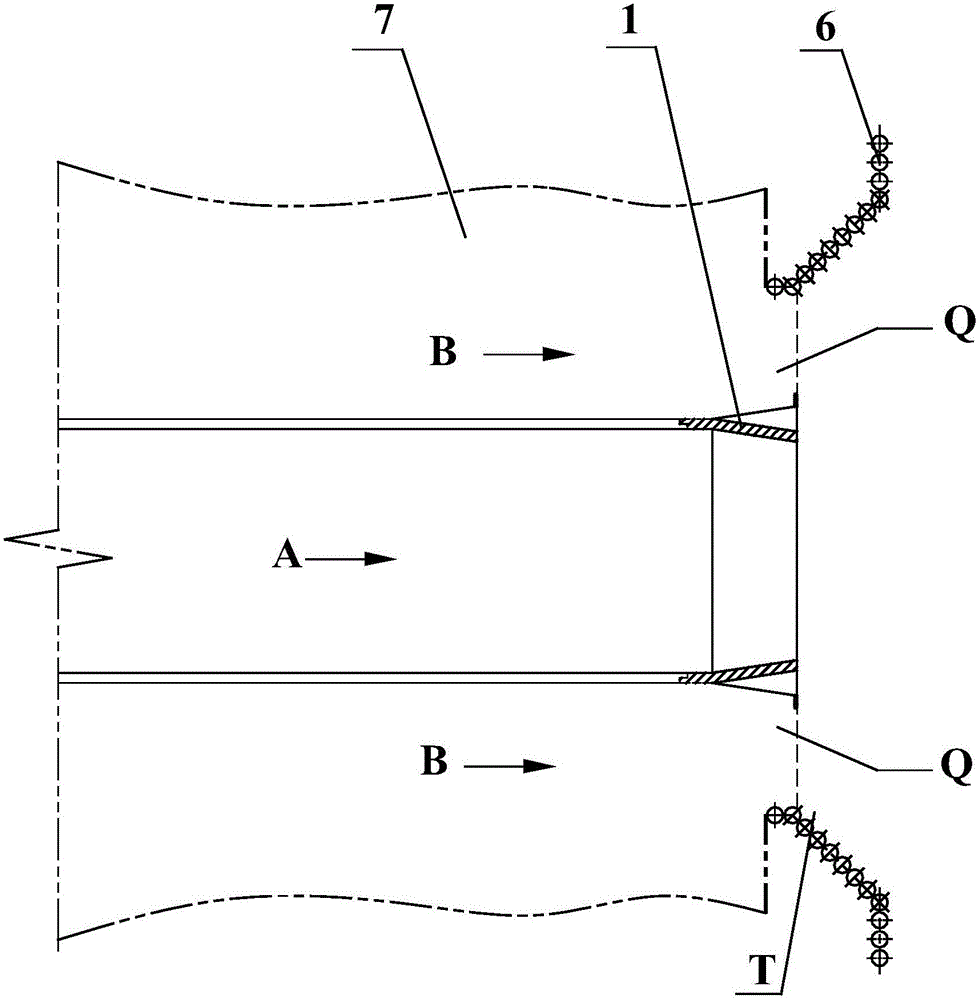

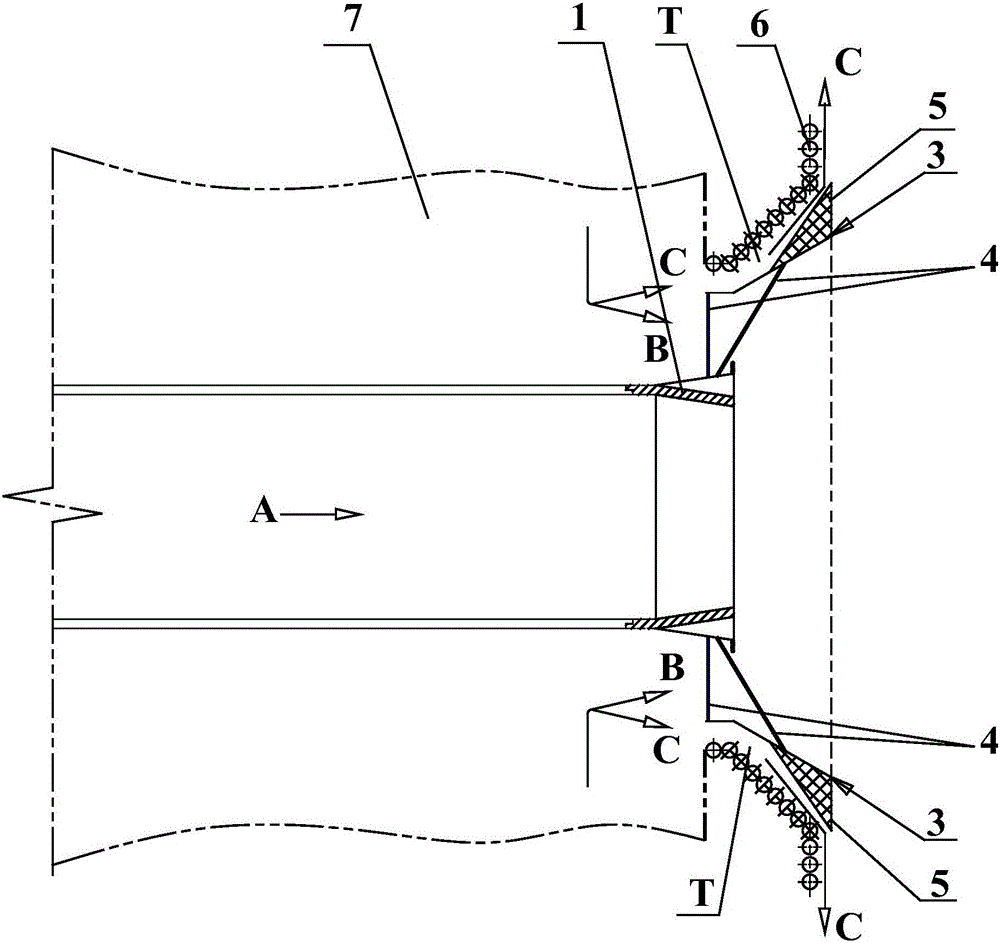

[0035] Such as figure 2 As shown, a multi-directional jet type swirl pulverized coal burner of the present invention is installed in the air box 7 outside the coal-fired boiler, and is connected with the opening on the furnace water wall 6. The primary air pulverized coal nozzle 1, an annular secondary air flow nozzle Q is formed between the outer periphery of the primary air pulverized coal nozzle 1 and the opening on the furnace water wall 6, and a wall-adhering wind guide tube 3 is arranged inside the secondary air flow nozzle Q , an annular wall-adhering air jet nozzle T is formed between the wall-adhering wind guide tube 3 and the opening on the furnace water wall 6, and the flow area of the outlet of the wall-adhering air jet nozzle T accounts for 3% of the outlet flow area of the secondary air flow nozzle Q ~18%; when optimizing the design, the flow area of the wall-adhering air jet nozzle T outlet accounts for 3~12% of the flow area of the secondary air flow n...

Embodiment 2

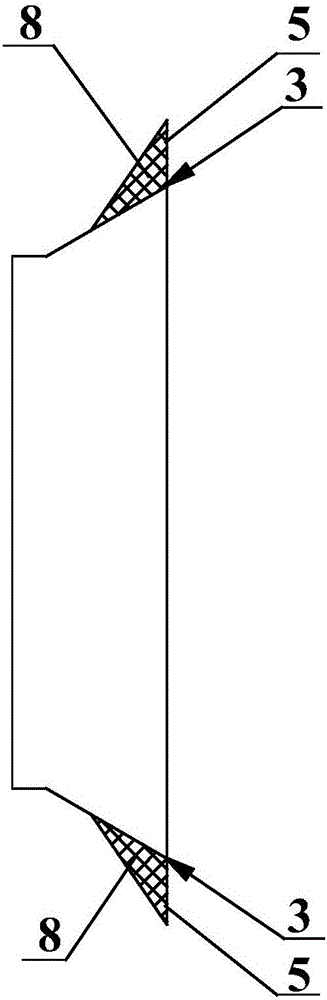

[0043] Such as Figure 10 As shown, another multi-directional jet swirl pulverized coal burner of the present invention has the same overall structure as that of Embodiment 1, except that the flanging air guide flange 5 is arranged at a position flush with the furnace water wall 6 , so that the wall-adjacent wind can be injected into the furnace at an angle relative to the water wall 6 of the furnace.

Embodiment 3

[0045] Such as Figure 11 As shown, the third multi-directional jet type swirl pulverized coal burner of the present invention has the same overall structure as that of Embodiment 1, except that the outer periphery of the primary air pulverized coal nozzle 1 is provided with a secondary air guide tube 2, attached to The wall wind guide tube 3 is arranged between the secondary air guide tube 2 and the spout on the furnace water wall 6 , and is rigidly connected to the outer wall of the secondary air guide tube 2 through the supporting device 4 .

[0046] When it works, coal powder and primary air form a primary air pulverized coal airflow A, which is sprayed into the furnace by the primary air pulverized coal nozzle 1; The wind flow B is blown into the furnace from the inside and outside of the wall of the secondary wind guide tube 2 in two ways, and is mixed with the primary air pulverized coal flow A to fully burn the pulverized coal and play a combustion-supporting role. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com