A device that uses crude chemical synthesis gas to increase solid waste burnout

A crude synthesis gas and solid waste burnout technology, which is applied in the direction of incinerators, combustion types, combustion methods, etc., can solve the problems of insufficient fuel combustion, high cost of use, increased solid waste burnout, etc., and achieves easy access , low cost, and the effect of increasing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

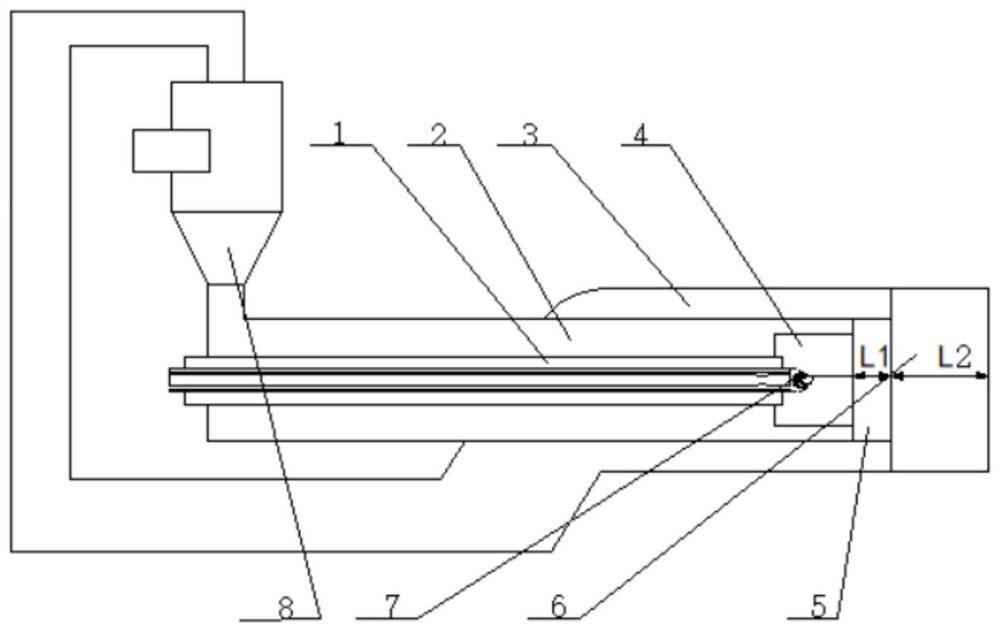

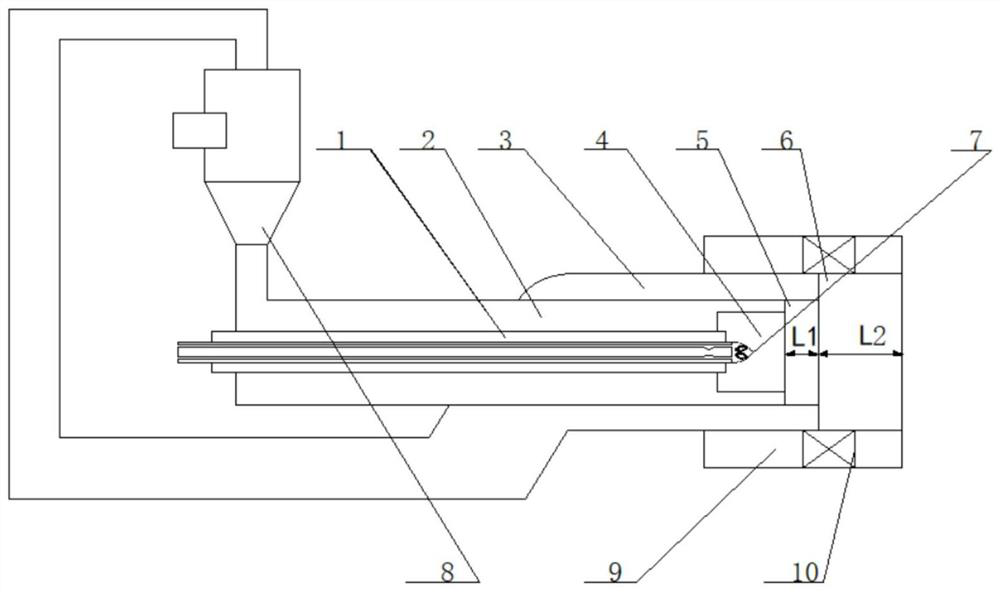

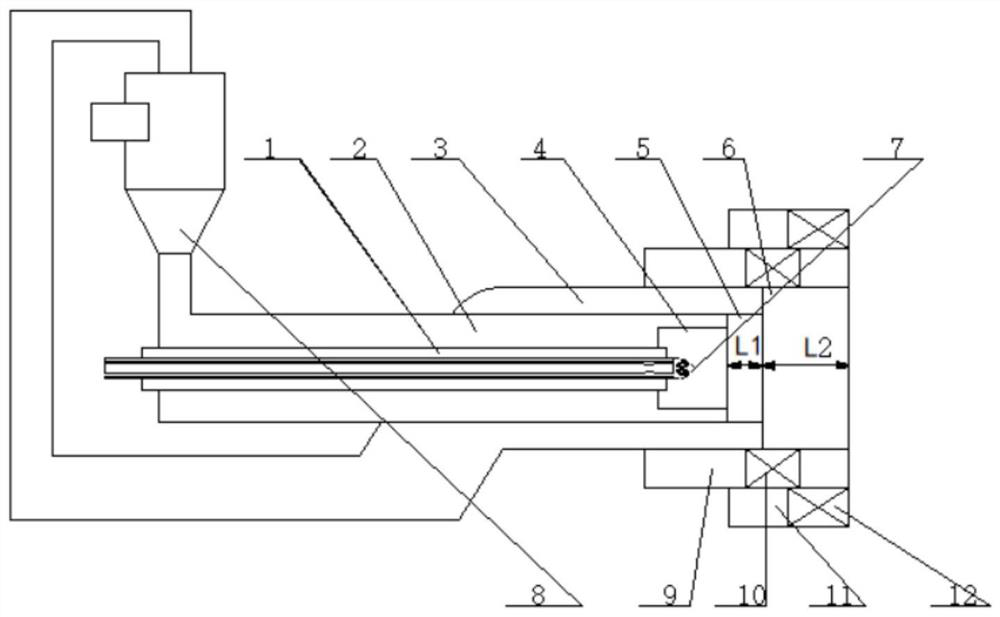

[0026] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a device for increasing solid waste burnout using crude chemical synthesis gas described in this embodiment includes a central chemical crude synthesis gas pipeline 1, a first solid waste air powder pipeline 2, and a second solid waste powder pipeline 3. Primary combustion chamber 4, secondary combustion chamber 5, tertiary combustion chamber 6, ignition gun 7 and cyclone separator 8;

[0027] One end of the second solid waste powder pipe 3 is provided with a three-stage combustion chamber 6, the outer surface of the second solid waste powder pipe 3 is provided with a through hole, and the first solid waste air powder pipe 2 is inserted inside the through hole , the inside of the first solid waste air powder pipeline 2 is provided with a primary combustion chamber 4 and a secondary combustion chamber 5 in sequence from left to right, and an input port is provided on the upper surface of th...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the combustion device described in Embodiment 1. In this embodiment, a device that uses chemical crude synthesis gas to increase solid waste burnout, the first-stage Combustion chamber 4, secondary combustion chamber 5 and tertiary combustion chamber 6 are arranged coaxially.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the combustion device described in Embodiment 2. In this embodiment, a device that uses chemical crude synthesis gas to increase solid waste burnout, the first-stage Combustion chamber 4, secondary combustion chamber 5 and tertiary combustion chamber 6 are arranged in communication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com