Automatic control high temperature waste heat recovery system used in process of preparing acid by sulphur

A waste heat recovery system and a technology for sulfuric acid production, which are applied in the fields of chemical industry, energy saving, and environmental protection, can solve the problems of boiler equipment design without a matching automatic control system, the safety of waste heat boiler system not being guaranteed, and the inability to meet the large-scale sulfuric acid production process. To achieve the effect of long equipment life cycle, high reliability and reliability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

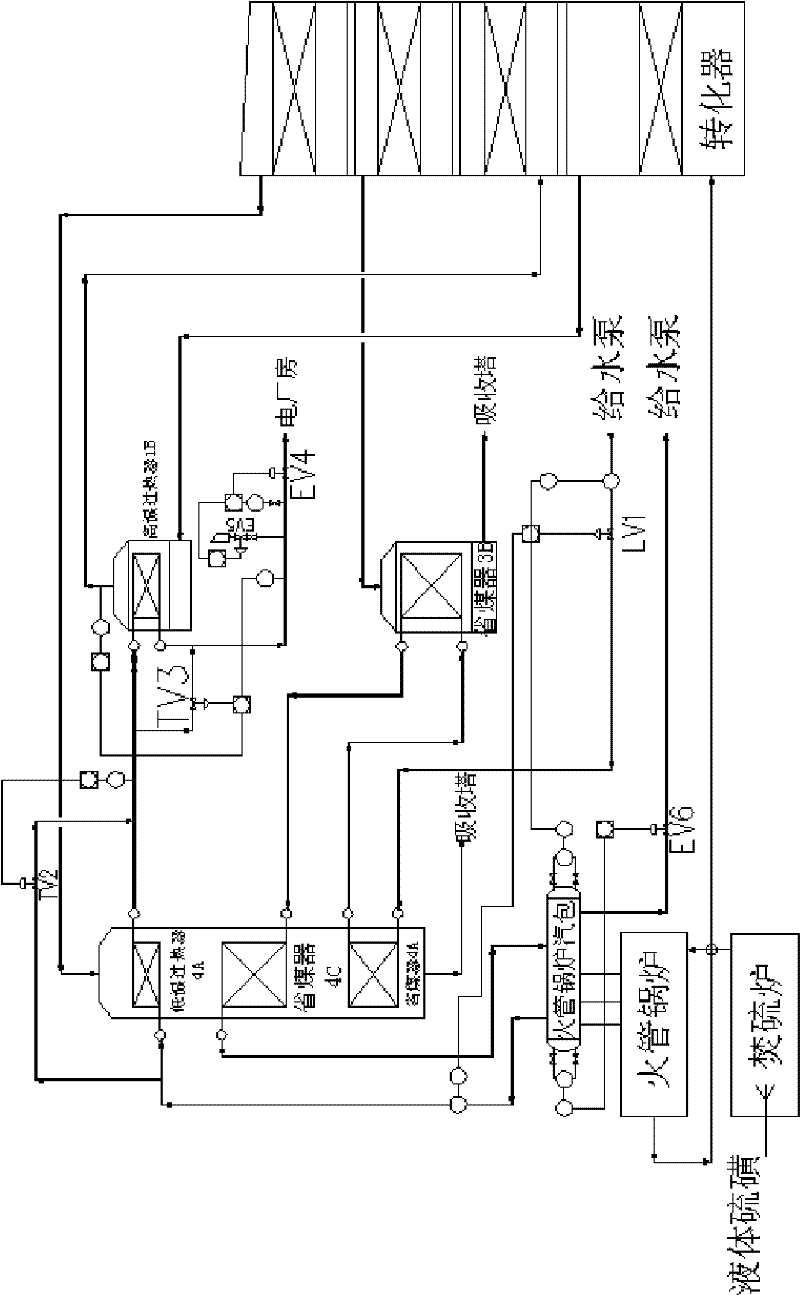

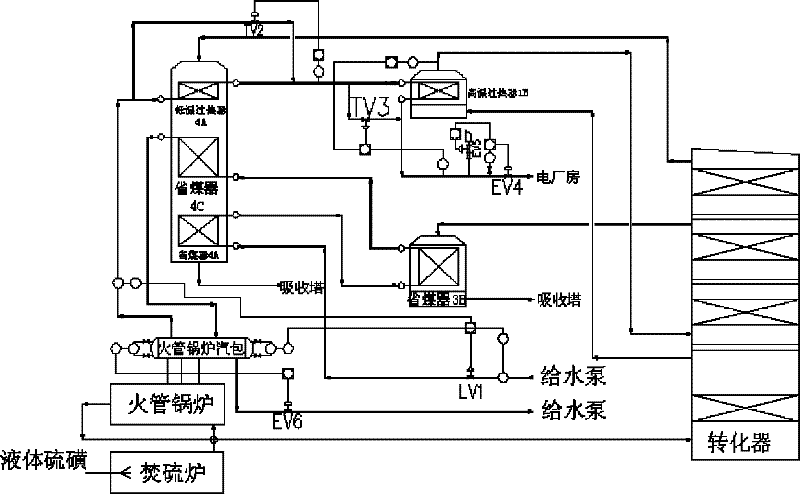

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] see figure 1 , In the acid plant with sulfur as raw material, there is a large amount of high and medium temperature waste heat and low temperature waste heat that can be recovered. This system discusses the recovery system that releases high- and medium-temperature potential heat from sulfur burning and conversion processes.

[0019] The fire tube boiler is installed at the outlet of the sulfur incinerator to recover the high-temperature waste heat generated by the incineration of liquid sulfur in the sulfur incinerator to cool the furnace gas from 1100°C to about 420°C. The heat of the furnace gas is absorbed by the boiler water to generate saturated steam.

[0020] The low-temperature superheater 4A is installed at the outlet of the fourth stage of the converter to recover the medium-temperature waste heat generated during the conversion of sulfur dioxide into su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com