High efficient boiler

A high-efficiency boiler technology, applied in steam boilers, boiler smoke tubes/fire tubes, boiler drums/box-type headers, etc., can solve low thermal efficiency, difficult to remove carbon and ash deposits in fire tubes, and boiler exhaust Smoke heat loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

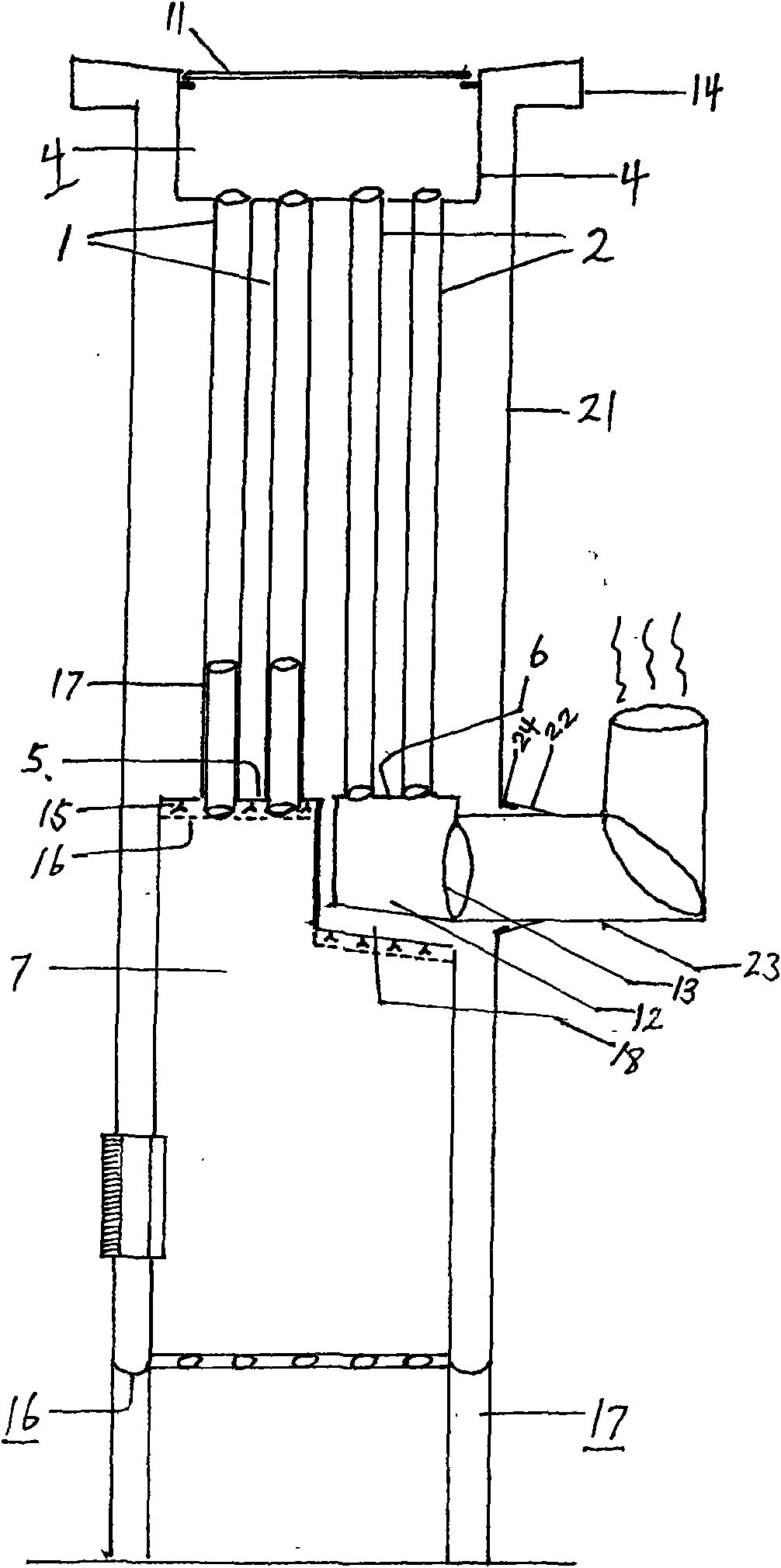

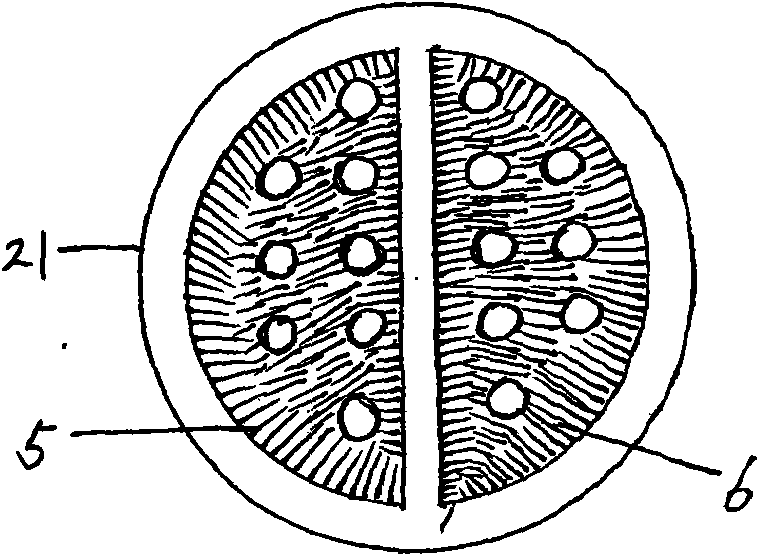

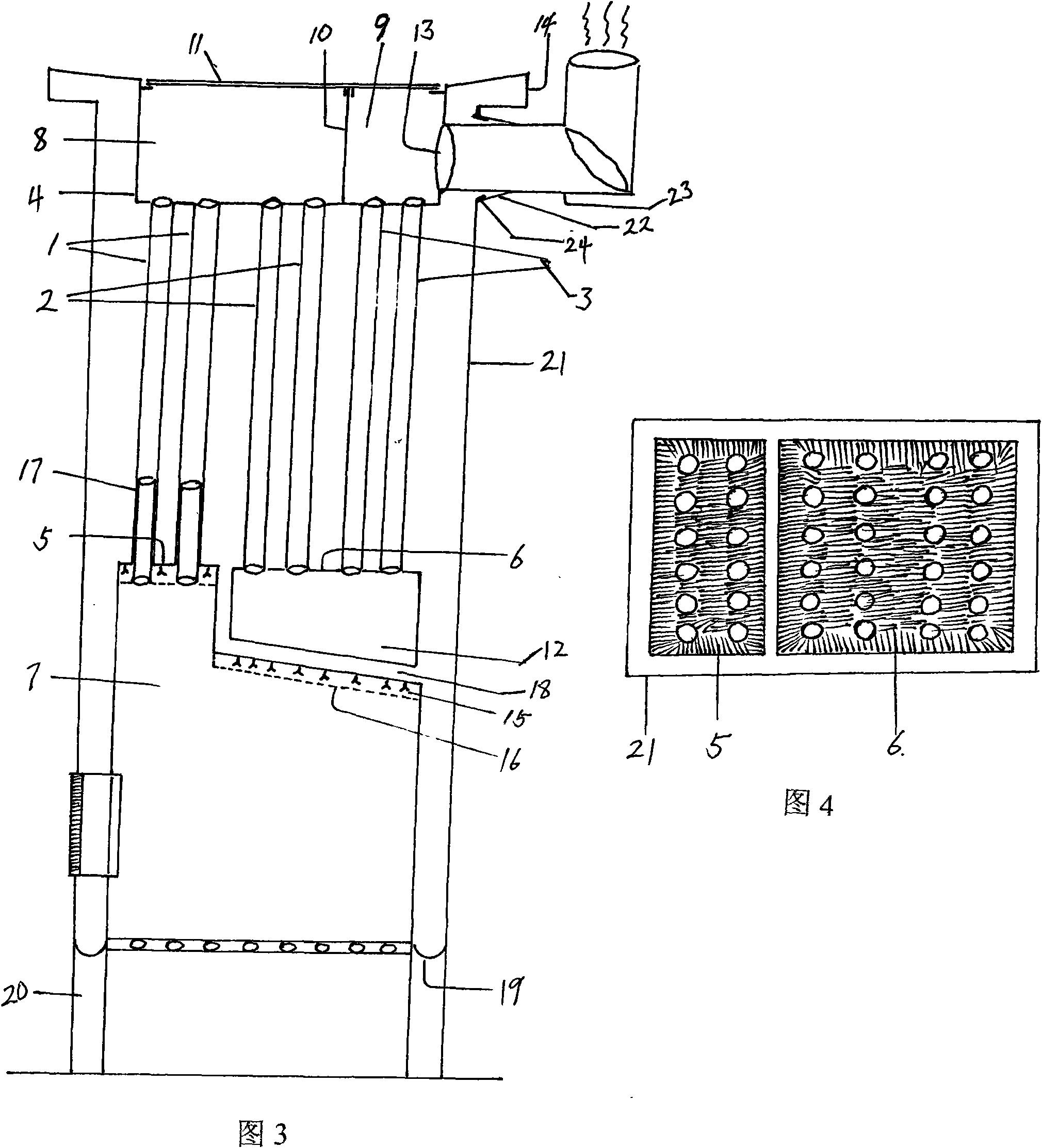

[0015] figure 1 The pyrotechnic tube bundles in can be divided into high-temperature flue gas first-pass pyrotechnic tube bundles (1) and high-temperature flue gas second-pass pyrotechnic tube bundles (2), which are located between the upper tube sheet (4) and the lower tube sheet, and the upper tube sheet is The tub-shaped structure tube plate, and the lower tube plate is divided into the lower tube plate (5) of the first-stroke pyrotechnic tube bundle and the lower tube plate (6) of the second-stroke pyrotechnic tube bundle. The lower tube plate of the first-pass pyrotechnic tube bundle is also the high-position furnace roof of the boiler, below which is the combustion chamber, and under the lower tube plate of the second-pass pyrotechnic tube bundle is the lower smoke chamber, which is a water-cooled structure. The lower smoke chamber is located at a low position above the furnace roof. The pyrotechnic tube bundle of the heat-absorbing structure is composed of several vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com