Vertical small-capacity fire-tube boiler

A fire-tube boiler and small-capacity technology, applied in the field of hot water boilers, can solve the problems of low evaporation intensity, large smoke and wind resistance, complex structure, etc., to increase the heat transfer area, increase the return of the flue gas, and lengthen the flue gas flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

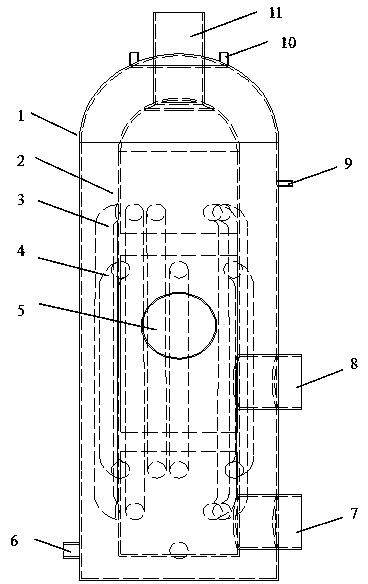

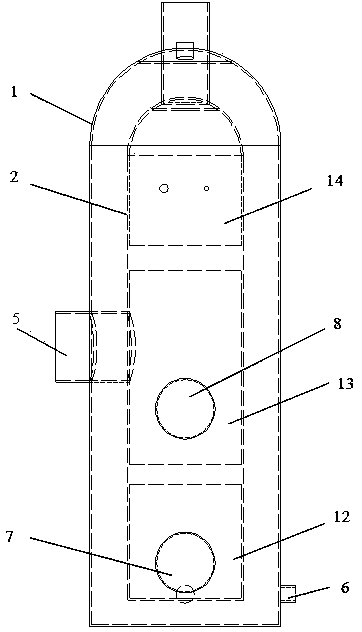

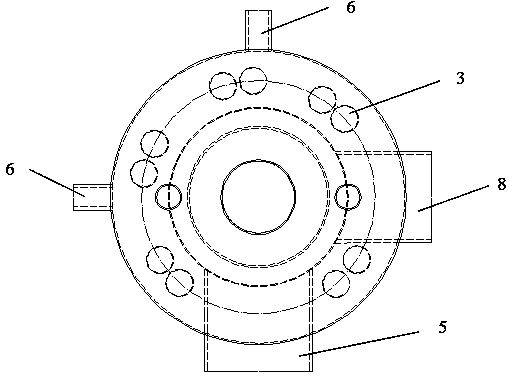

[0020] First determine the rated evaporation and pressure of the boiler, and then select high-standard pipes according to relevant national regulations; figure 1 Shown is a new vertical small-capacity fire-tube boiler, including a pot shell, a smoke exhaust pipe 11, a burner 5, a fire tube and a smoke chamber; The outer cavity 15 is formed between the inner shells 2, and the smoke chamber is arranged in the heat-preservation inner shell 2, which are the first smoke chamber 14, the second smoke chamber 13 and the third smoke chamber 12 from top to bottom; Shell 2 A smoke exhaust pipe 11 is arranged on the top of the shell and protrudes outside the thermal insulation shell 1. The pressure valve 10 is installed on the top of the thermal insulation shell 1 and located on both sides of the smoke exhaust pipe 11. The water inlet 9 is set on the upper right outside the thermal insulation shell 1, and the water outlet is set. At the bottom left of the thermal insulation shell 1; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com