Low NOx fire tube boiler

A fire tube boiler and flame technology, applied in the field of low NOx fire tube boilers, can solve problems such as low heat output and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0114] Figure 10 Is a schematic diagram of an experimental setup 1000 for determining the effect of dilution distance between a fuel nozzle and a perforated flame holder according to one embodiment. In this experimental setup, the test ignition was carried out using the following conditions:

[0115] The fuel is methane.

[0116] Fuel pressure varied, but was about 12 psig flux.

[0117] The fuel nozzle (pinhole) diameter is 0.11".

[0118] "Close" the damper in the exhaust stack with about a 1 / 4" gap at all times around the damper. The stack size is about 12 square inches. The 1 / 4" gap keeps the exhaust stack damper from closing completely.

[0119] The air source (intake air) is natural draft and confined in a 3" hole concentrically positioned with the fuel nozzle tube covering approximately the center 1 / 4" of the 3" hole.

[0120] 3% O in the stack 2 The NOx comparison below.

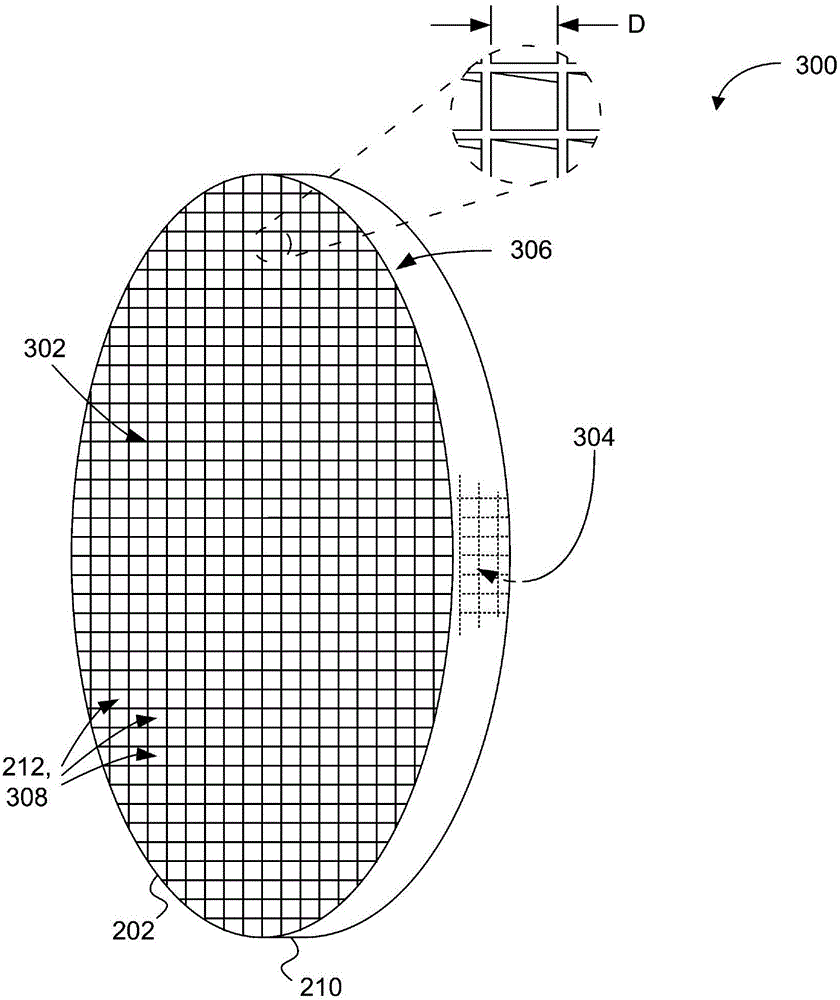

[0121] The overall thickness (L dimension) of the perforated flame holder was 4". The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com