Low discharge high energy efficiency vertical shell type water-fire tube boiler

A low-emission, boiler-shell technology, applied in steam generators, steam generation, lighting and heating equipment, etc., can solve the problems of large smoke and wind resistance, easy wear of smoke pipes, large gaps, etc., to increase boiler length, reduce Cost, effect of shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

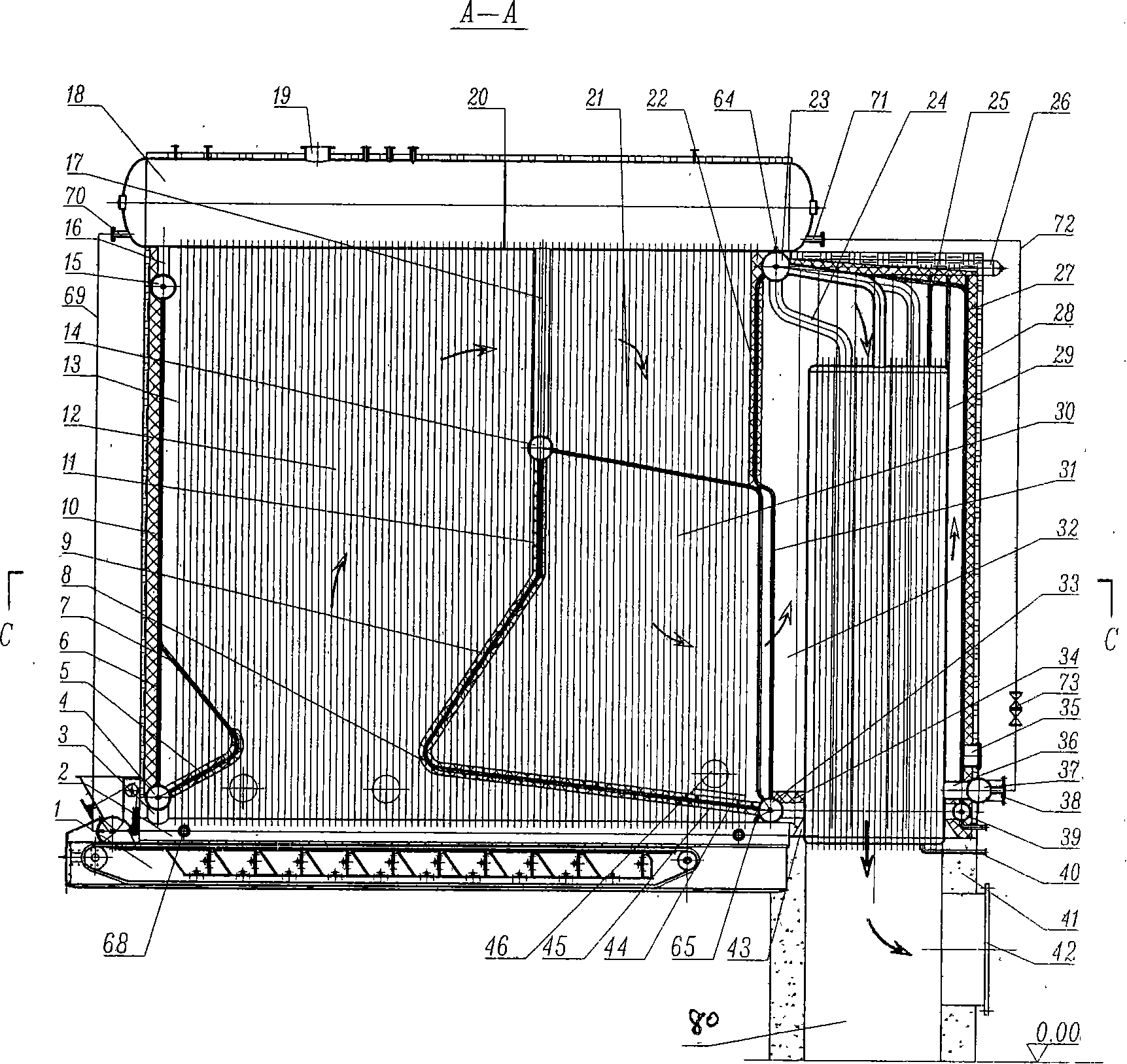

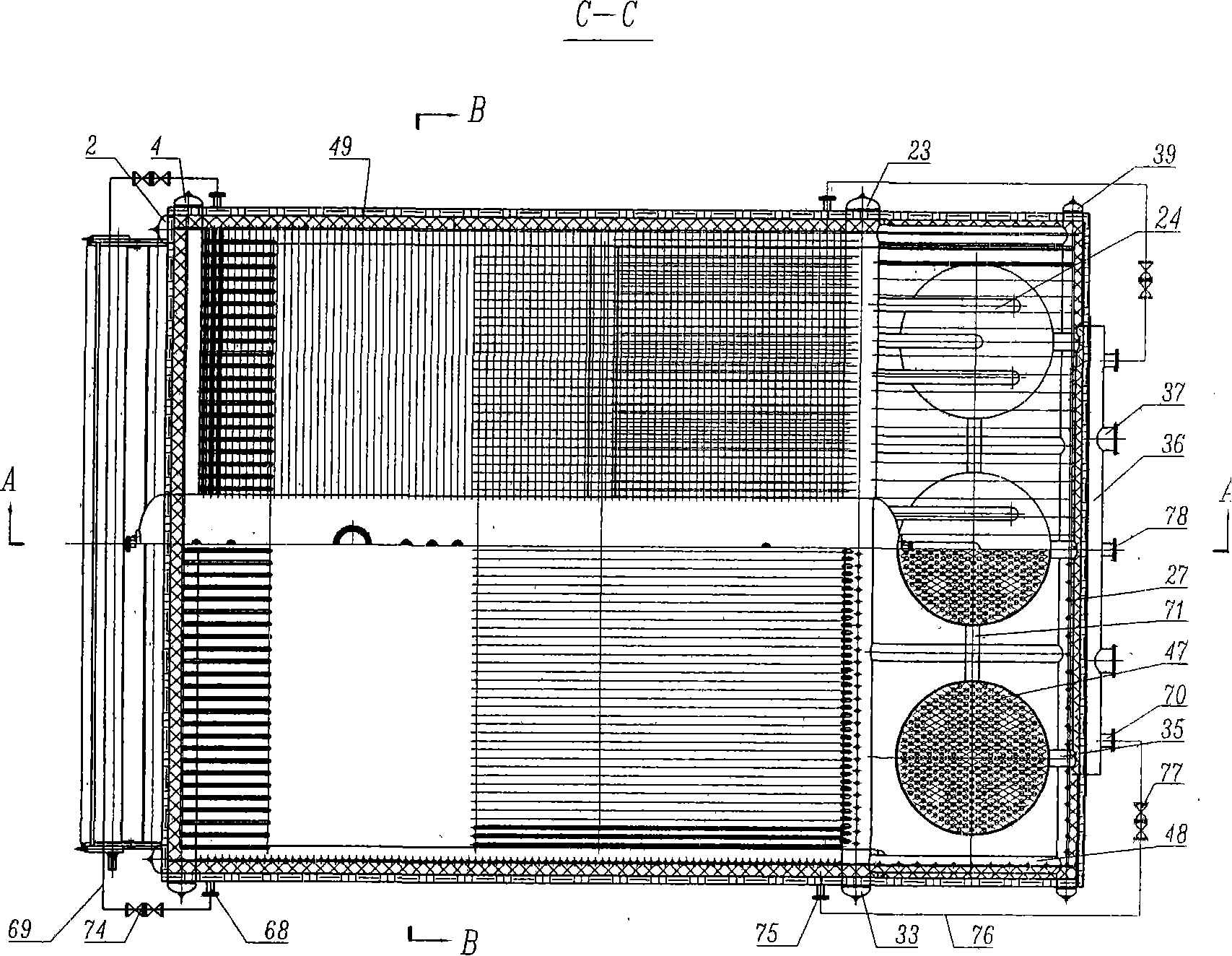

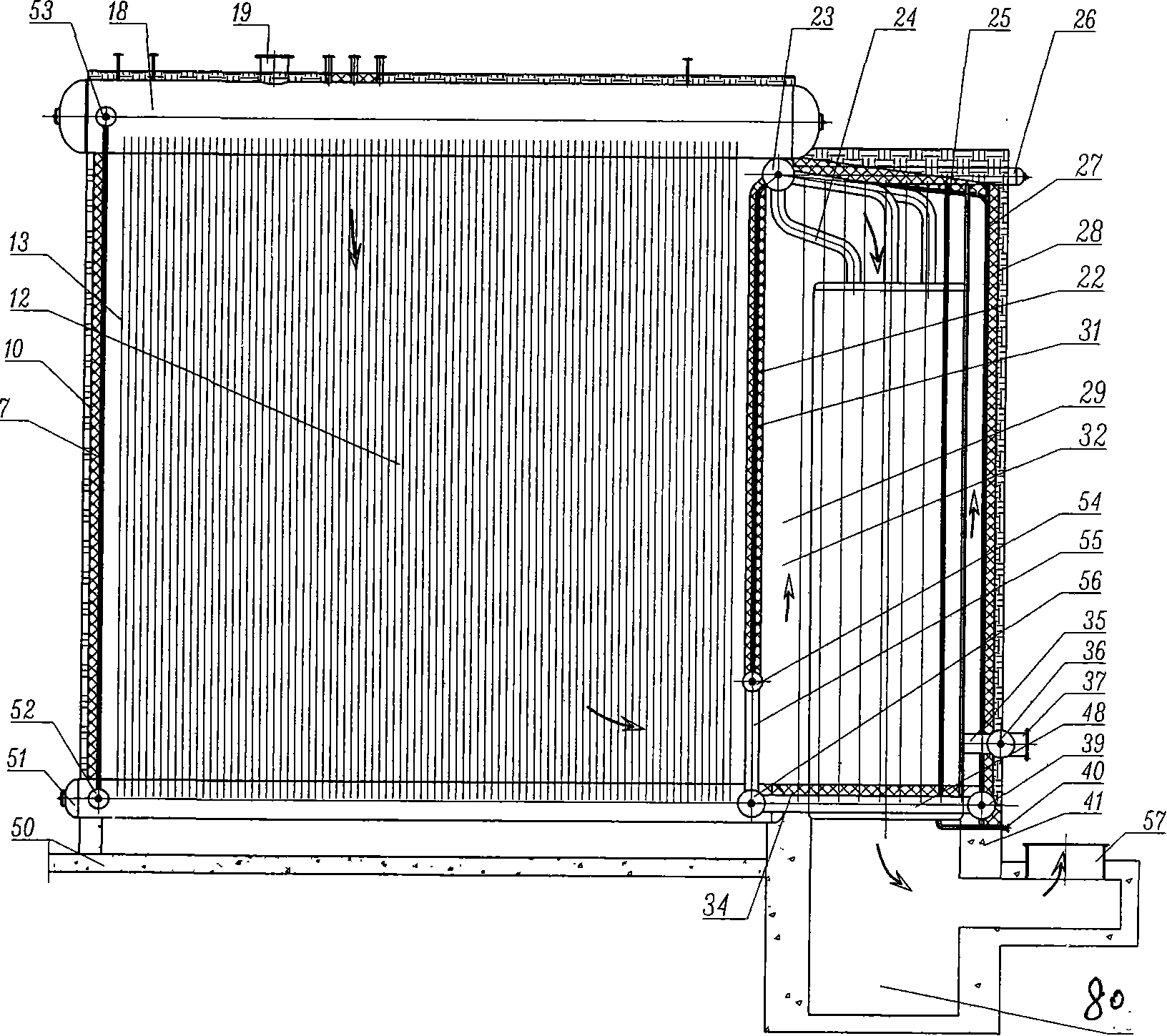

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings; a low-emission, high-energy-efficiency vertical shell-type water-fire tube boiler, comprising: a vertical drum (18), a vertical header (2) (15) (14) (23 ) (33); vertical drum (29), threaded smoke pipe (47), water wall tube (13) convection tube bundle (21) (31) rear box tube (27) side wall tube (25) etc. constitute. It is characterized in that the inner end of the water-cooled wall pipe (13) is evenly connected to the lower part of the longitudinal center of the vertical drum (18), and its lower end is connected longitudinally and evenly to the upper center of the lower vertical header (2). The upper ends of the arch pipes (7) (9) are respectively connected to the lower transverse centers of the upper transverse headers (15) (14) of the front and rear arches respectively, and the lower ends thereof are respectively connected to the lower transverse headers (4) ( 34) Med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com