A process of using rice husk powder and petroleum coke powder as mixed fuel for calcining white cement rotary kiln

A technology of mixing fuel and petroleum coke powder, which is used in the petroleum industry, fuel, solid fuel and other directions, can solve the problems of slow combustion speed, poor combustion conditions, slow heat release speed, etc. , The effect of reducing the load of the mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

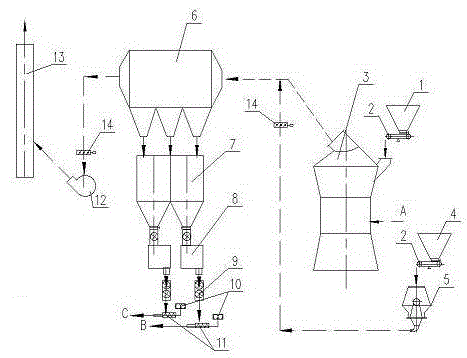

[0015] combined with figure 1 described as follows:

[0016] Petroleum coke stored in the petroleum coke silo (1) is measured by a belt scale (2) at a mass ratio of 90% of the total fuel, and then fed into a petroleum coke mill (3) for grinding until the residue on a 0.08mm square hole sieve is less than 1%. The rice husk stored in the rice husk bin (4) is measured by the belt scale (2) according to the total fuel mass ratio of 10%, and then fed to the rice husk grinder (5) to be crushed into rice husk powder less than 0.8mm, and the rice husk is crushed The discharge pipe of the machine is connected to the kiln head petroleum coke grinding system, and the pulverized rice husk powder is sucked into the bag filter (6) by the exhaust fan (12) of the petroleum coke grinding system and the petroleum coke entering the bag filter at the same time After the powder is mixed and collected, it is sent to two mixed fuel bins (7) by a screw conveyor or a rigid impeller feeder, and the mi...

Embodiment 2

[0018] In Example 1, the mass ratio of rice husk powder and petroleum coke was adjusted from 1:9 to 2:8, and other processes were the same as in Example 1. Compared with petroleum coke fuel, it can reduce the ignition temperature by about 120°C, reduce the fuel burnout temperature by about 100°C, and reduce the heat consumption of white cement clinker calcination by about 10%.

Embodiment 3

[0020] In Example 1, the mass ratio of rice husk powder and petroleum coke was adjusted from 1:9 to 3:7, and other processes were the same as in Example 1. Compared with petroleum coke fuel, it can reduce the ignition temperature by about 150°C, reduce the fuel burnout temperature by about 150°C, and reduce the heat consumption of white cement clinker calcination by about 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com