evaporative burner

An evaporative, burner technology, applied in the direction of burner, combustion type, combustion method, etc., to reduce incomplete combustion, prolong life, and improve ignitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] "constitute"

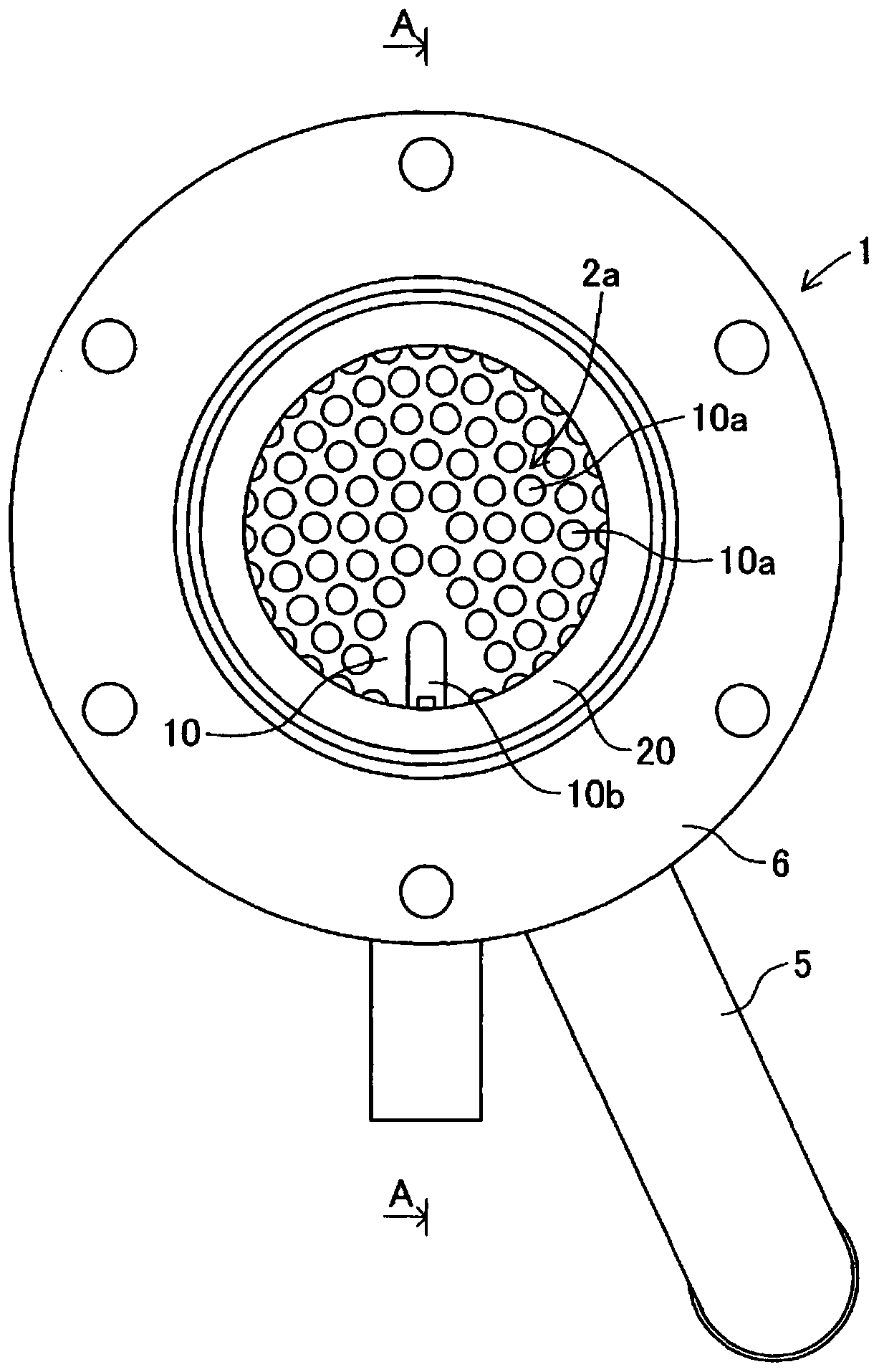

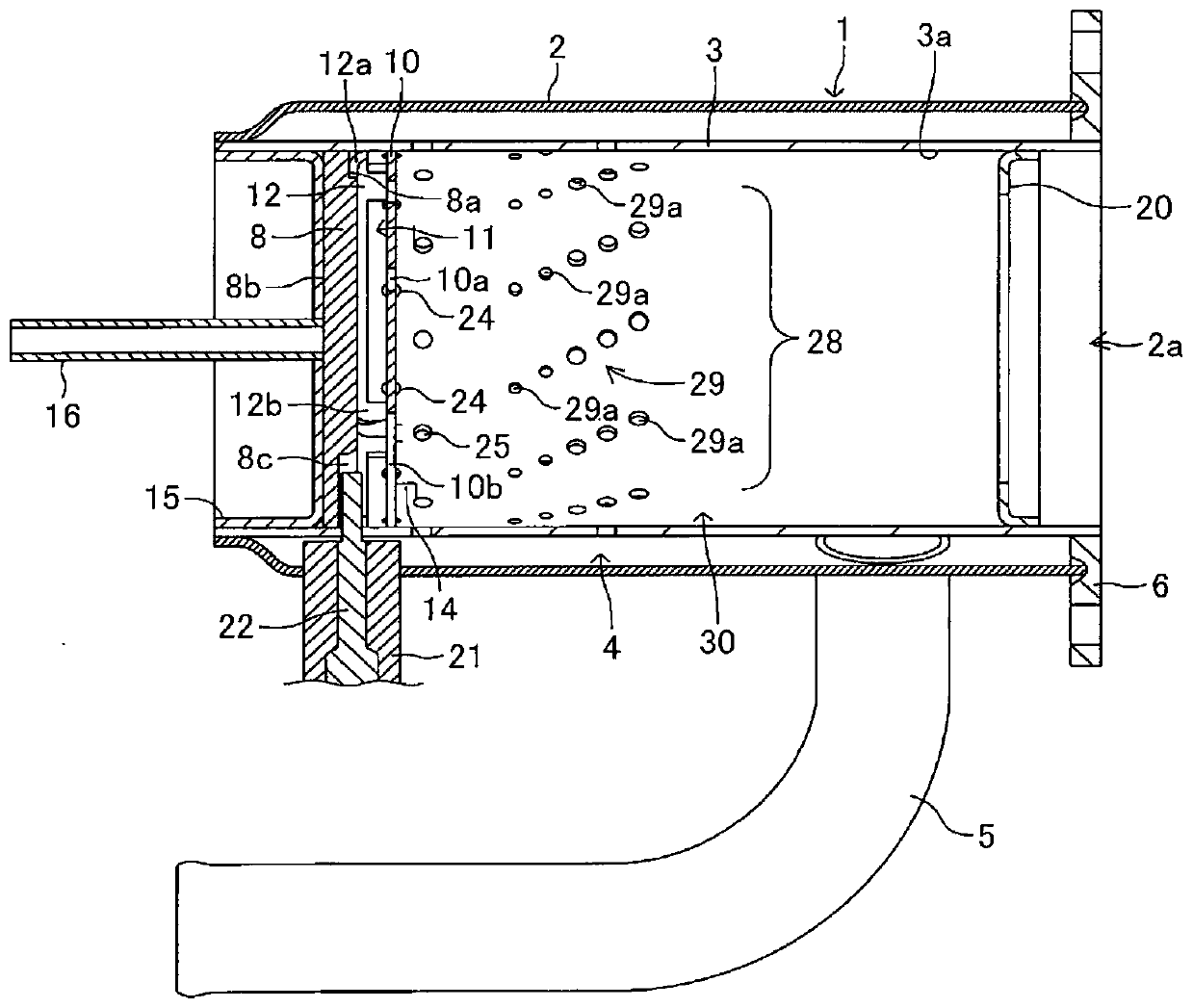

[0079] figure 1 It is a schematic diagram which shows the state which looked at the evaporative burner 1 of Example 1 of this invention from a downstream side. figure 2 Yes figure 1 A-A line sectional view. In the following description, the upper side in the vertical direction ( figure 1 as well as figure 2 The upper side of the paper surface) is referred to as "upper", and the opposite side, that is, the lower side, is referred to as "lower". In addition, towards figure 2 On the paper, let the left side be the "upstream side", and the opposite side, that is, the right side, shall be the "downstream side".

[0080]The evaporative burner 1 includes an outer casing 2 and an inner casing 3 arranged inside the outer casing 2 . The shapes of the outer casing 2 and the inner casing 3 are not particularly limited, and can be appropriately designed, for example, according to the application of the evaporative burner 1 and the use environment. In the pr...

Embodiment 2

[0144] As described above, according to the evaporative burner 1 of the first embodiment of the present invention, it is possible to simultaneously solve the first problem and the second problem, that is, the first problem is to supply an amount of air suitable for the ignition device to ignite the fuel to the ignition In order to improve the ignitability of the evaporative burner and prolong the life of the liquid wick, the second problem is to prevent the infiltration of the fuel into the liquid wick and to improve the heat transfer from the ignition mechanism to the liquid wick. Improve the ignitability of evaporative burners.

[0145] The evaporative combustor 1a of the second embodiment of the present invention described below aims to solve the third problem of reducing the air shortage that causes incomplete combustion of fuel on the downstream side of the combustion chamber.

[0146] "Structure and Action"

[0147] The evaporative combustor 1 a is characterized in that...

Embodiment 3

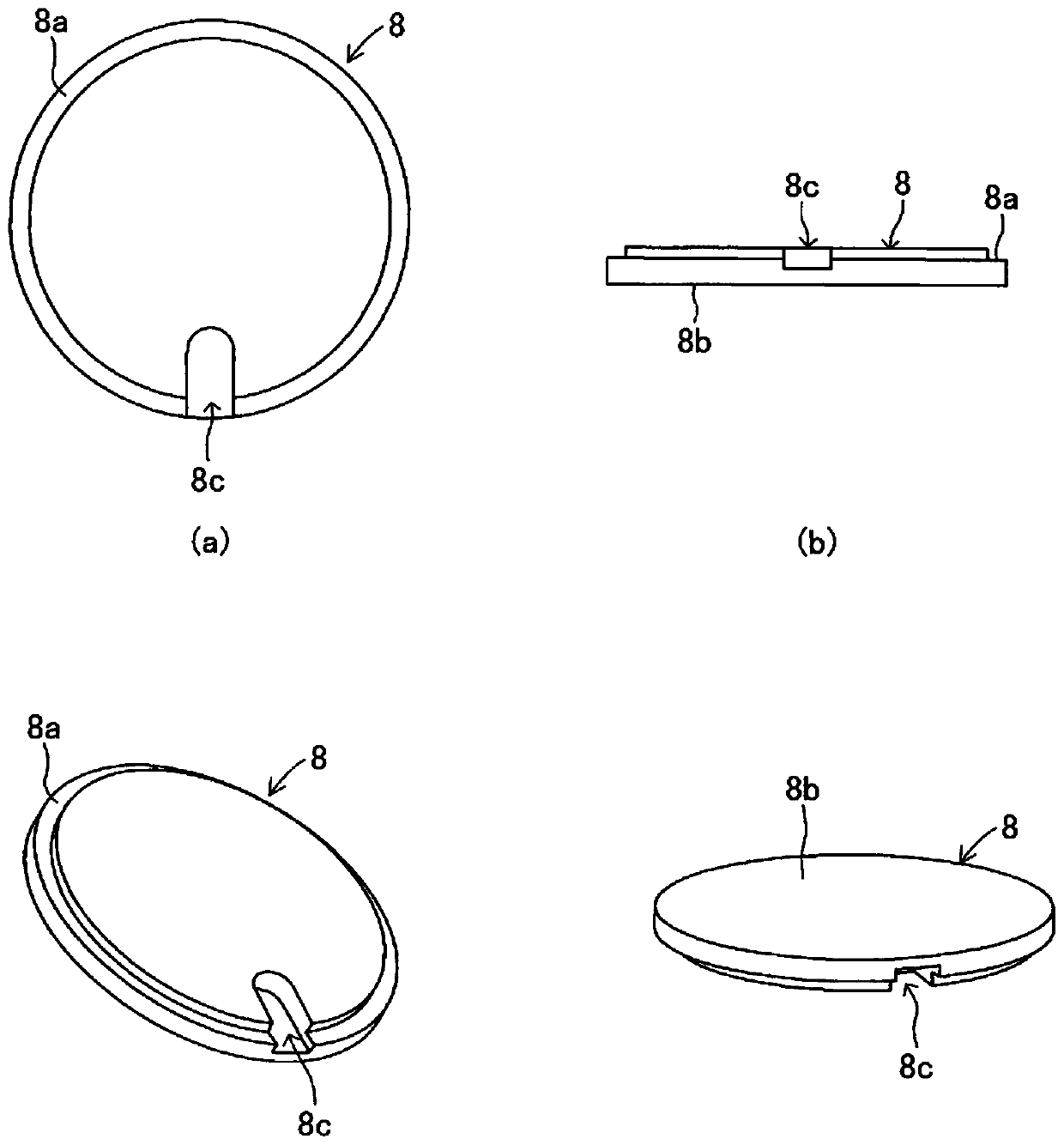

[0166] In the above-described evaporative burners 1 and 1a, the promoting member having a planar (plate-like) shape as a whole is used, except for a partial curved portion. However, in the plate-shaped promoting member, deformation (thermal deformation) of the promoting member may occur due to a temperature change accompanying the combustion of fuel. Therefore, in Example 3 of the present invention, the rigidity (section modulus) of the promotion member is increased, and the thermal deformation of the promotion member accompanying the combustion of the fuel is reduced.

[0167] "structure"

[0168] like Figure 23 As shown, in the evaporative combustor 1b according to the third embodiment of the present invention, the promoting member 50 is constituted by a plate-shaped member having a curved surface shape with a central portion protruding toward the upstream side. In addition, the impregnating member 48 is also constituted by a plate-shaped member having a curved surface sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com